In industrial scenarios such as smart manufacturing, energy management, and intelligent logistics, the efficiency of device interconnection and data flow directly determines production effectiveness and safety levels. However, the industrial environment features diverse device protocols, large data volumes, and high real-time requirements, making it difficult for traditional gateways to meet complex demands. As a "bridge" connecting devices to the cloud, Industrial IoT Gateways, especially industrial-grade gateways with edge computing capabilities, are becoming key infrastructure for enterprise digital transformation. This article will explore the core value of Industrial IoT Gateways from technical analysis to scenario applications.

An Industrial IoT Gateway is a combination of hardware and software located between the perception and network layers of the IoT. It undertakes multiple roles, including data collection, protocol conversion, edge computing, and security protection. In industrial scenarios, its value is more evident in its compatibility with heterogeneous devices, low-latency response capabilities, and localized data processing to reduce cloud dependency.

● Protocol Compatibility: Support industrial protocols such as Modbus, OPC UA, and Profinet, as well as cloud protocols like MQTT and HTTP.

● Edge Computing: Enable data preprocessing, logic control, and AI inference at the gateway to reduce cloud transmission delays.

● High Reliability: Adapt to harsh environments with high temperatures, vibrations, and electromagnetic interference, supporting 7×24-hour stable operation.

● Security Protection: Resist cyberattacks through device authentication, data encryption, firewalls, and other technologies.

● Easy Operation and Maintenance: Support remote configuration, firmware upgrades, and fault diagnosis to reduce on-site maintenance costs.

Processor: Utilize high-performance ARM Cortex-A series chips (e.g., dual-core 1GHz) to balance computing power and energy efficiency.

Communication Interfaces: Integrate Ethernet, RS485/232, Wi-Fi, and 4G/5G to support multi-link redundancy backup.

Industrial-Grade Design: Feature fanless cooling, IP65 protection rating, and a wide operating temperature range (-40°C to 85°C) to suit outdoor or workshop deployments.

Operating System: Based on a lightweight Linux system, support containerized deployment to isolate different business modules.

Edge Computing Framework:

Data Preprocessing: Filter redundant data and aggregate key metrics (e.g., calculate the average vibration value of equipment).

Logic Control: Implement localized linkage through a rule engine (e.g., automatically start the cooling system when the temperature exceeds the limit).

AI Inference: Integrate TensorFlow Lite or ONNX Runtime to support lightweight model deployment (e.g., equipment failure prediction).

Protocol Conversion Engine: Built-in with 200+ industrial protocol libraries and support custom protocol development to lower integration thresholds.

TSN (Time-Sensitive Networking): Combined with 5G, it meets the deterministic low-latency requirements of industrial scenarios (e.g., robot collaborative control).

Digital Twin: The gateway serves as a "digital mirror" of physical devices, supporting real-time data mapping and remote debugging.

AI Empowerment: Upgrade from "data forwarding" to "intelligent decision-making," such as predicting bearing life through vibration analysis.

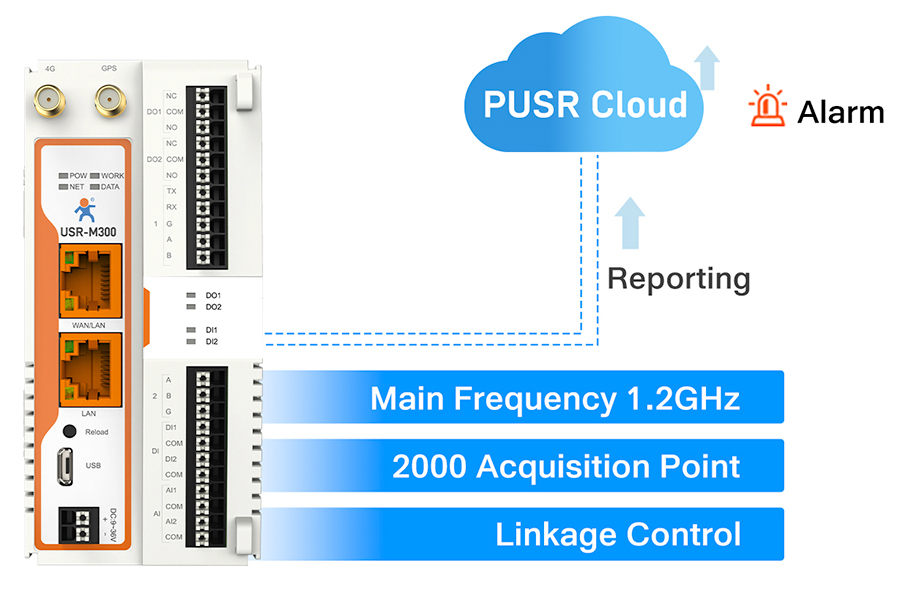

Scenario Example: In an automotive welding production line, the USR-M300 gateway connects PLCs, sensors, and robots. Through edge computing, it analyzes welding current fluctuations in real time and automatically adjusts parameters to avoid cold solder joints while uploading key data to the cloud for quality traceability.

Value: Reduce manual intervention, improve product yield, and minimize downtime.

Scenario Example: In a photovoltaic power station, the gateway aggregates data from inverters, electricity meters, and environmental monitoring stations. Through edge computing, it optimizes power generation efficiency (e.g., dynamically adjusting inverter output based on light intensity) and sends real-time alerts for abnormal data (e.g., excessively high component temperatures) to the operation and maintenance platform.

Value: Increase power generation, extend equipment lifespan, and reduce operation and maintenance costs.

Scenario Example: In an automated warehouse, the gateway connects AGV trolleys, stacker cranes, and the WMS system. Through edge computing, it implements path planning and obstacle avoidance decisions while synchronizing inventory data to the cloud for dynamic scheduling.

Value: Improve warehouse turnover rates and reduce manual operation errors.

| Parameter | Basic Gateway | Edge Computing Gateway (e.g., USR-M300) |

| Processor | Single-core ARM Cortex-M | Dual-core ARM Cortex-A (1GHz+) |

| Edge Capabilities | Data filtering only | Support rule engine and AI model inference |

| Protocol Support | 10-20 industrial protocols | 200+ protocol libraries, support custom development |

| Industrial Design | IP40 (indoor) | IP65 (dustproof and waterproof), wide operating temperature |

● Edge Computing Capabilities:

Built-in rule engine supports "IF-THEN" logic programming (e.g., "If temperature > 80°C and humidity > 70%, start the fan").

Integrate TensorFlow Lite to deploy pre-trained vibration analysis models for real-time equipment anomaly detection.

Data Aggregation: Support minute-level aggregation of data from 1,000+ sensors to reduce cloud transmission volume.

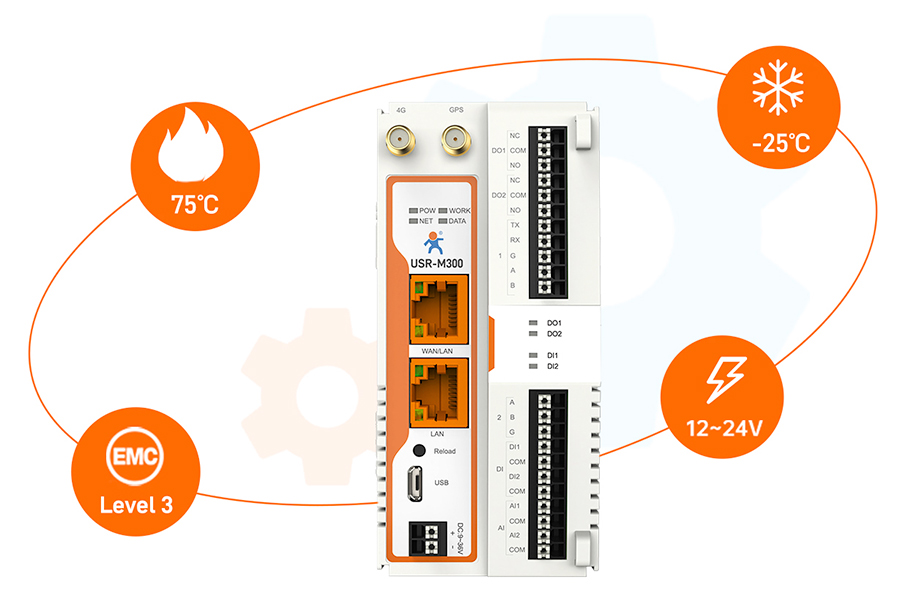

● Industrial-Grade Design:

Fanless cooling adapts to environments from -40°C to 85°C and passes EMC Level 3 certification for electromagnetic interference resistance.

Support dual 4G/5G redundant communication to ensure reliable data transmission.

● Ease of Use:

Provide a visual configuration tool for protocol conversion and rule setting without programming.

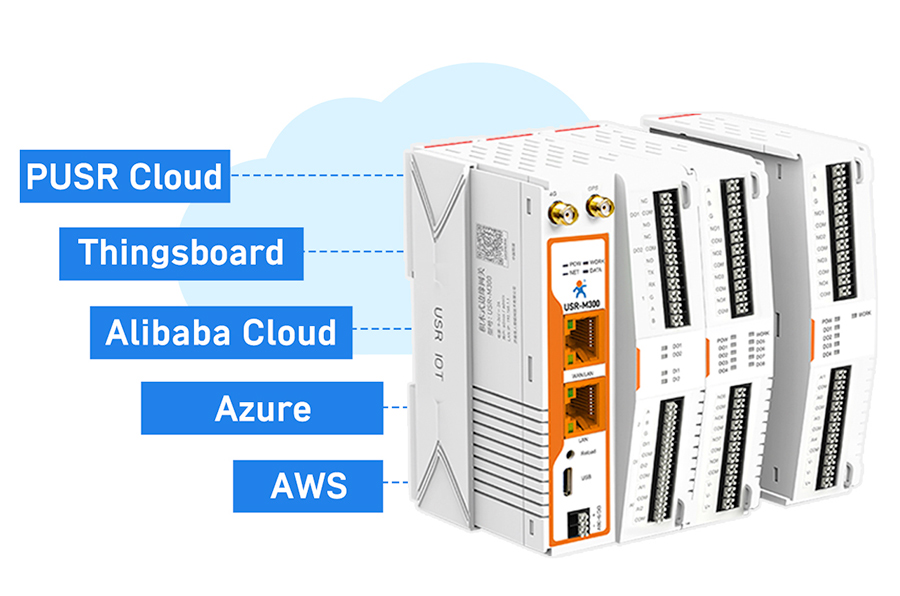

Support integration with mainstream platforms such as Alibaba Cloud, Huawei Cloud, and AWS to lower integration costs.

Avoid "Pseudo-Edge": Some gateways only support simple data filtering and cannot implement localized decision-making. Clarify requirements before purchase.

Focus on Ecosystem Compatibility: Choose gateways that support open protocols (e.g., MQTT over TLS) and mainstream cloud platforms to avoid vendor lock-in.

Value Long-Term Service: Industrial scenarios require a 5-10 year lifecycle. Prioritize vendors offering long-term firmware updates and technical support.

AI-Native Gateways: Future gateways will integrate dedicated AI chips (e.g., NPUs) for more complex local inference (e.g., visual defect detection).

Self-Organizing Networks: Use AI to dynamically optimize communication paths and enhance network robustness in complex industrial environments.

Low Carbonization: Edge computing reduces cloud data transmission, lowering overall energy consumption and supporting "dual carbon" goals.

Gateway: The "Last Mile" of Industrial Intelligence

In the wave of Industry 4.0, Industrial IoT Gateways have evolved from "data channels" to "intelligent hubs." Edge computing gateways like the USR-M300 are helping enterprises overcome challenges such as data silos, response delays, and operation and maintenance costs through localized decision-making capabilities and industrial-grade reliability. Choosing a suitable gateway is not just an investment in hardware but also a foundation for future intelligent upgrades.