How Industrial Panel PCs Reshape Carbon Footprint Tracking and Emission Reduction in Energy Storage Systems Under the Global Goal of Carbon Neutrality

Driven by the global goal of carbon neutrality, energy storage systems, as the core carrier of energy transition, are undergoing a paradigm shift from "scale expansion" to "intelligent low-carbon". According to the International Energy Agency's forecast, the global installed energy storage capacity will exceed 1.5 TW by 2030. However, traditional energy storage systems face challenges in accurately tracking carbon footprints and achieving dynamic emission reductions due to issues such as isolated equipment, fragmented data, and delayed control. Against this backdrop, industrial panel PCs, with their full-link capabilities of "connection-sensing-decision-making-execution," are reshaping the technological ecosystem of energy storage systems and becoming key infrastructure for achieving carbon neutrality goals.

Tracking the carbon footprint of energy storage systems requires covering the entire lifecycle, from raw material extraction, manufacturing, transportation, and installation to operation and maintenance. However, traditional energy storage systems generally face three major technological bottlenecks:

Through a "cloud-edge-end" collaborative architecture, industrial panel PCs have built a "digital nervous system" for carbon footprint tracking and emission reduction in energy storage systems, with core value manifested in four key areas:

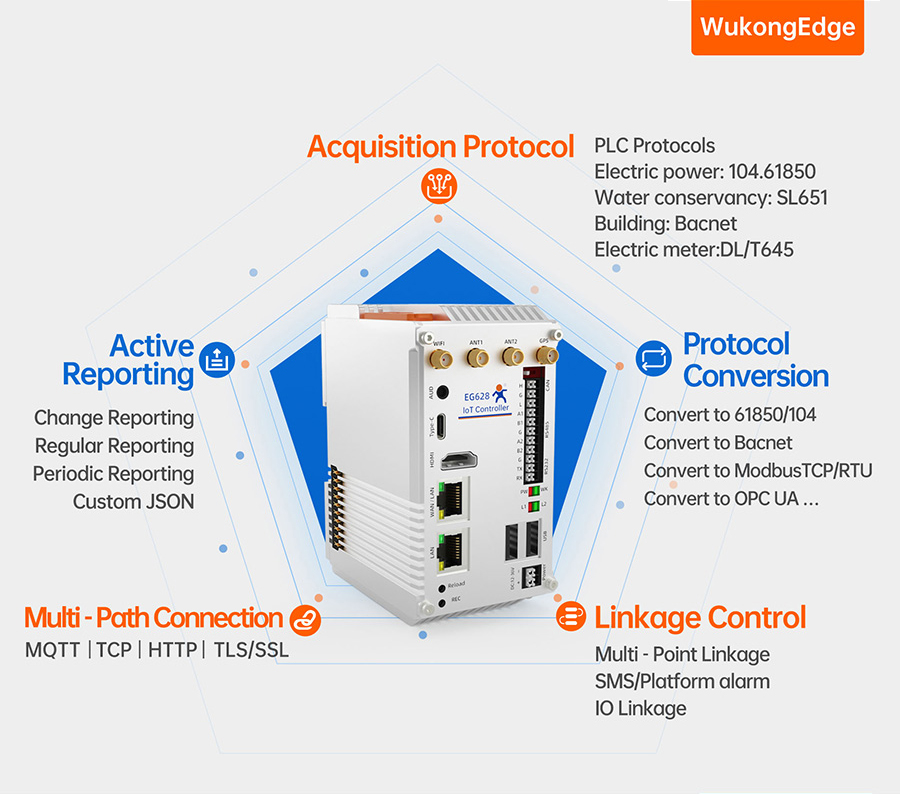

Industrial panel PCs support over 30 industrial protocols, including MQTT, CoAP, and OPC UA, enabling seamless integration with energy storage equipment from different manufacturers. For example, the USR-EG628 controller adopts a Hardware Abstraction Layer (HAL) design, allowing functions like serial communication and GPIO control to be implemented through API calls without requiring attention to low-level register configurations. An energy storage manufacturer developed a BMS data collection module based on this controller, completing protocol integration with a certain brand of batteries in just two weeks, improving development efficiency by 80% compared to traditional methods.

Additionally, industrial panel PCs can achieve dynamic protocol conversion through edge computing engines. For example, an energy storage power station used the protocol conversion plugin of the open-source platform ThingsBoard to convert non-standard protocols into MQTT format, improving data upload efficiency by 70% without requiring additional gateway program development.

By integrating AI algorithms and digital twin technology, industrial panel PCs have constructed dynamic carbon footprint models for energy storage systems. For example, a zero-carbon industrial park's energy storage system, based on real-time data collected by an industrial panel PC and combined with an LSTM neural network prediction model, can dynamically calculate carbon emission intensity under different charging/discharging strategies. When excess photovoltaic power is generated, the system automatically prioritizes the "photovoltaic-energy storage-load" path to avoid indirect carbon emissions from reverse power flow to the grid. When grid carbon intensity is low, the system increases electricity purchases from the grid through demand response programs to achieve "low-carbon electricity consumption."

In the industrial sector, an energy storage system at a steel plant integrated grid electrical partitioning technology through an industrial panel PC to analyze carbon emission intensity at each node in the power system. Based on real-time carbon price data, the system dynamically adjusted the proportion of self-generated green electricity and purchased electricity, increasing carbon trading revenue by 27% year-on-year.

Through open APIs and standardized interfaces, industrial panel PCs enable deep collaboration between energy storage systems, renewable energy generation, load-side equipment, and carbon trading markets. For example, an industrial and commercial energy storage project built a collaborative control module for "photovoltaic-energy storage-charging piles-electric vehicles" based on an industrial panel PC: when photovoltaic power generation exceeds load demand, the system automatically stores excess electricity in energy storage batteries and prioritizes charging electric vehicles; when the battery's State of Charge (SOC) drops below 30%, the system purchases electricity from the grid through demand response programs while participating in carbon trading markets to generate revenue.

In the transportation sector, a logistics company achieved collaboration between its energy storage system and electric truck fleet through an industrial panel PC: the system optimized charging plans based on data such as truck routes, cargo loads, and battery status, reducing the fleet's average daily carbon emissions by 18%.

Equipment failures in energy storage systems not only result in direct economic losses but also increase indirect carbon emissions through energy consumption and spare part transportation during maintenance. Industrial panel PCs continuously monitor key parameters such as battery temperature, voltage, and internal resistance, and use machine learning algorithms to predict equipment lifespans, providing 30-day advance warnings of potential failures. For example, after adopting an industrial panel PC, an energy storage power station reduced unplanned downtime by 40% and equipment maintenance costs by 25%, indirectly reducing carbon emissions by approximately 120 tons per year.

A zero-carbon technology park deployed over 2,000 IoT sensor nodes to collect real-time energy consumption data from photovoltaic power generation, energy storage equipment, and air conditioning systems. Through collaboration between an industrial panel PC and a big data platform, the park constructed a three-dimensional visual carbon flow atlas: red represents high-carbon emission areas (e.g., data centers), green represents carbon absorption areas (e.g., rooftop photovoltaics), and dynamic arrows indicate the direction of energy flow and carbon emission intensity. Based on an LSTM neural network prediction model, the system can predict the park's carbon emission trends seven days in advance, providing decision-making support for managers. For example, during an extreme weather warning, the system adjusted the energy storage system's charging/discharging strategy in advance, avoiding increased grid electricity purchases due to a sudden drop in photovoltaic power generation and indirectly reducing carbon emissions by approximately 50 tons.

A high-energy-consuming manufacturing enterprise developed an analysis module that links equipment energy consumption with production processes based on an industrial panel PC. The system collected data such as welding robot current and stamping machine pressure to establish a dynamic balance model between energy consumption and production capacity. When abnormal energy consumption is detected in a device, the system automatically adjusts the production plan and stores excess electricity in energy storage batteries for use during subsequent peak production periods. This model reduced the enterprise's energy consumption per unit of product by 15% and annual carbon emissions by approximately 800 tons.

A smart home manufacturer launched an IoT energy storage controller that integrates home photovoltaic power generation, energy storage batteries, and electric vehicle charging piles. The system automatically optimizes equipment operation strategies based on data such as electricity price fluctuations, carbon emission intensity, and user habits. For example, when electricity prices are low and grid carbon intensity is low, the system prioritizes charging electric vehicles; when sunlight is abundant, the system stores excess electricity in batteries and shuts off municipal power supply. This model reduced the average annual household electricity bill by 30% and carbon emissions by 40%.

As AI, digital twins, blockchain, and other technologies deepen their integration with industrial panel PCs, carbon footprint tracking and emission reduction in energy storage systems will advance to a higher stage:

On the journey toward global carbon neutrality, industrial panel PCs have evolved from "technical tools" to "strategic assets." They not only solve the "data silo" problem in carbon footprint tracking for energy storage systems but also unlock their low-carbon potential through capabilities such as dynamic optimization, cross-system collaboration, and predictive maintenance. In the future, as the technological ecosystem continues to evolve, industrial panel PCs will become the "digital engine" driving the energy storage industry toward the "dual carbon" goals, promoting the energy system toward a smarter, greener, and more sustainable direction.