In the wave of Industry 4.0 and digital transformation, Internet of Things (IoT) technology is reshaping core scenarios such as production, logistics, and energy management. According to IDC predictions, the number of global IoT device connections will exceed 41 billion by 2025, with industrial devices accounting for over 30%. However, the integration of massive devices, the flow of heterogeneous data, and real-time requirements pose stringent challenges to the reliability, security, and processing efficiency of IoT networks.

As the core hub connecting the perception layer (devices) and the network layer (cloud/local platforms), the IoT gateway is not just a "bridge" for data transmission but also a "firewall" for security protection and a "decision-making center" for edge intelligence. This article will deeply analyze how IoT gateways become the "triangular cornerstone" of industrial IoT from three dimensions: key functions, security enhancement mechanisms, and data processing logic, and explore their practical value in scenarios such as smart manufacturing and energy management.

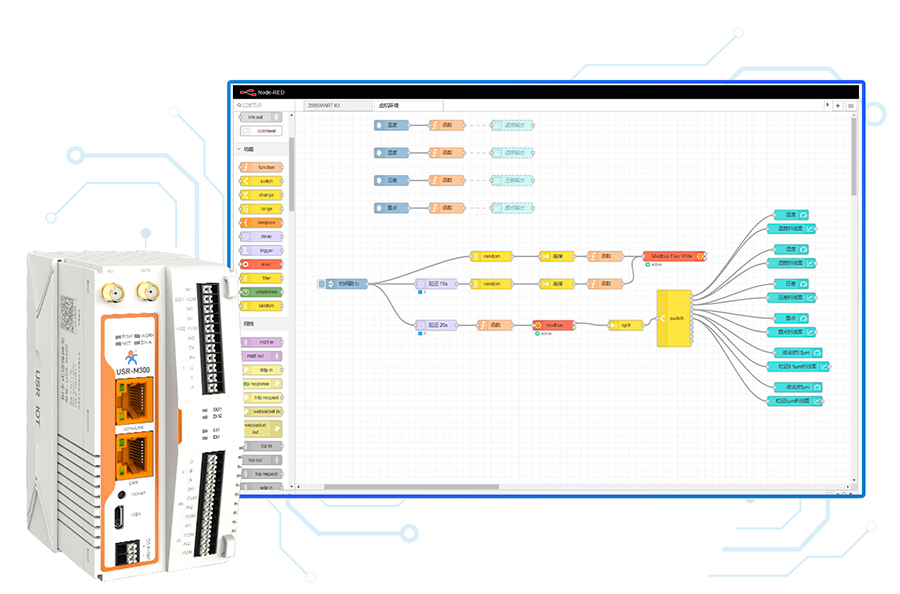

In industrial scenarios, device protocol fragmentation is the primary challenge. For example, PLCs may use Modbus, sensors rely on MQTT, and robot controllers adopt OPC UA. One of the core functions of an IoT gateway is protocol conversion, enabling seamless interconnection of heterogeneous devices through built-in protocol libraries (supporting over 200 industrial protocols) and custom development capabilities.

Technical Implementation:

Hardware Interfaces: Integration of RS485/232, Ethernet, Wi-Fi, LoRa, etc., covering short-range and long-range communication needs.

Software Engine: Rule-based protocol parsing and dynamic mapping, such as converting Modbus register data into JSON format for cloud parsing.

Case Study: In an automotive production line, the gateway connects over 300 devices (including welding robots, AGVs, and sensors), uploading data to the MES system through unified protocols to achieve visualization of the production process.

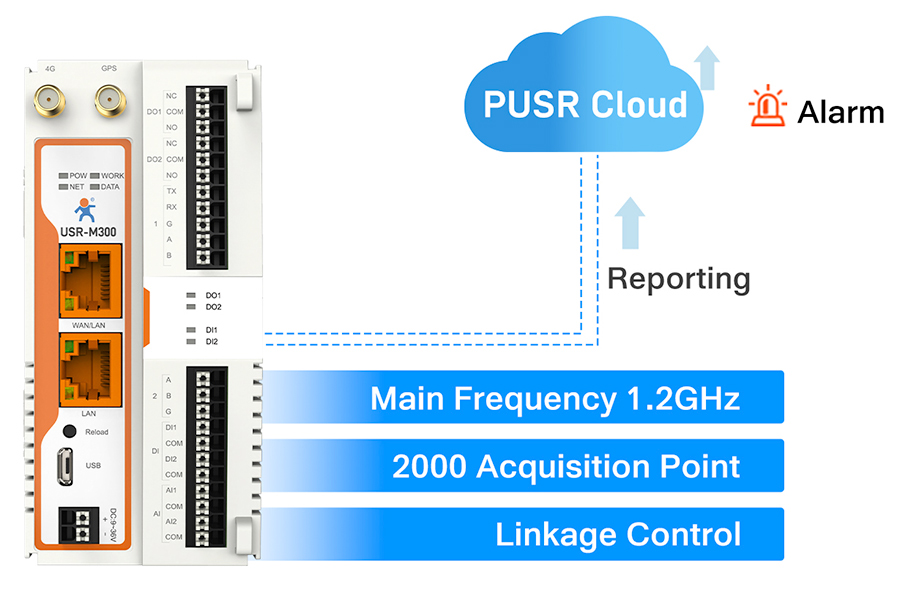

Traditional gateways only handle data forwarding, while modern industrial gateways, through edge computing capabilities, can execute logical control and real-time decision-making locally, reducing reliance on the cloud.

Core Functions:

Rule Engine: Supports "IF-THEN" logical programming (e.g., "if temperature > 80°C, trigger an alarm and start the cooling system").

Lightweight AI: Integrates TensorFlow Lite or ONNX Runtime to deploy pre-trained models (e.g., vibration analysis for predicting equipment failures).

Time-Sensitive Networking (TSN): Combined with 5G to meet deterministic low-latency requirements in industrial scenarios (e.g., robot collaborative control).

Value: In energy management scenarios, the gateway can analyze inverter data from photovoltaic power plants in real-time, dynamically adjusting output power to improve generation efficiency by 5%-10%.

Industrial devices are widely distributed, and on-site maintenance costs are high. Gateways enable "contactless" operations through remote configuration, firmware upgrades, and fault diagnosis functions.

Technical Implementation:

OTA (Over-the-Air) Updates: Supports secure remote firmware updates for devices, avoiding downtime.

Digital Twins: The gateway serves as a "digital mirror" of physical devices, mapping device status in real-time and supporting remote debugging.

Case Study: In a smart logistics warehouse, the gateway manages over 200 AGVs, reducing operations and maintenance costs by 30% through remote path planning and fault warnings.

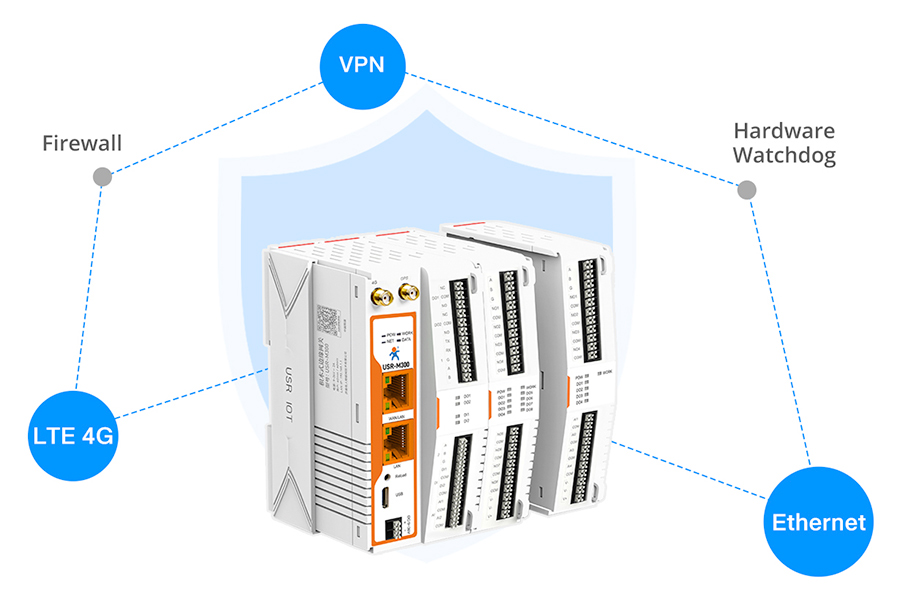

Industrial data (such as process parameters and device status) is highly sensitive and requires full encryption during transmission. Gateways support end-to-end encryption and secure protocol stacks to prevent data theft or tampering.

Technical Implementation:

Transport Layer Encryption: Supports TLS 1.3 and DTLS (for UDP scenarios) to ensure data integrity.

Application Layer Encryption: Encrypts key fields (such as device ID and timestamp) with AES-256, making it impossible for attackers to parse complete data even if keys are leaked.

Secure Tunnels: Establish virtual private networks (VPNs) through IPsec or WireGuard to isolate public network threats.

Case Study: In smart grids, the gateway encrypts and transmits telemetry data from substations, meeting IEC 62351 security standards and resisting APT attacks.

Traditional firewalls rely on static rules and struggle to cope with zero-day vulnerabilities and advanced persistent threats (APTs). Modern gateways integrate AI-driven intrusion detection systems (IDS) to analyze network traffic and device behavior in real-time, identifying abnormal patterns.

Technical Means:

Behavior Baseline Modeling: Establish normal device behavior models (such as communication frequency and data range) through machine learning to detect behaviors deviating from the baseline (e.g., sudden increases in sensor data).

Threat Intelligence Integration: Share attack signature libraries with cloud security platforms to update detection rules in real-time.

Microsegmentation: Divide the network into multiple security domains and automatically isolate infected devices upon detecting an attack to prevent lateral spread.

Case Study: In a smart manufacturing scenario, the gateway detected abnormal communication frequency from a PLC through traffic analysis and immediately cut off its network connection, avoiding production line downtime.

Data generated by industrial devices is characterized by high noise and redundancy. Gateways extract valuable information through data cleaning, filtering, and conversion, reducing cloud processing pressure.

Core Functions:

Noise Filtering: Remove invalid data (e.g., repeated readings from sensors in a stationary state).

Data Completion: Fill in missing values through interpolation algorithms (e.g., data lost by temperature sensors due to communication interruptions).

Unit Conversion: Unify data formats (e.g., convert Fahrenheit to Celsius) for easier cloud analysis.

Case Study: In a wind farm, the gateway performs smoothing processing on raw data from wind speed sensors, eliminating short-term fluctuations and improving the accuracy of power generation forecasts.

Directly uploading massive device data to the cloud can lead to bandwidth congestion and soaring storage costs. Gateways compress data volume while retaining key features through temporal and spatial aggregation.

Technical Implementation:

Temporal Aggregation: Summarize data by minute/hour (e.g., calculate average vibration values of devices).

Spatial Aggregation: Group and statistically analyze data from multiple devices in the same area (e.g., calculate the average temperature in a workshop).

Feature Extraction: Extract key dimensions from data through PCA (Principal Component Analysis) or autoencoders (e.g., dominant frequency components in vibration spectra).

Case Study: In a smart city, the gateway aggregates data from over 1,000 traffic sensors, reducing daily data volume from 10TB to 100GB and lowering cloud storage costs by 90%.

With the popularization of AI technology, gateways are evolving from "data transfer stations" to "edge intelligence nodes," enabling real-time decision-making through localized model inference.

Application Scenarios:

Predictive Maintenance: Deploy vibration analysis models to predict bearing failures 30 days in advance, avoiding unplanned downtime.

Quality Inspection: Detect product defects on the production line through image recognition models, reducing scrap rates.

Energy Optimization: Dynamically adjust device operating parameters (e.g., air conditioning temperature) based on reinforcement learning models to reduce energy consumption.

Technical Challenges:

Resource Constraints: Industrial gateways have limited computing power and memory, requiring optimization of model size (e.g., quantization and pruning).

Real-Time Requirements: Some scenarios (e.g., robot control) require model inference latency <10ms, necessitating hardware acceleration (e.g., NPU chips).

Case Study: In semiconductor manufacturing, the gateway deploys defect detection models, replacing manual visual inspection with AI automatic detection and improving product yield by 2%.

IoT gateways are not just "connectors" between devices and the cloud but also "fortresses" for security protection and "carriers" for edge intelligence. Through key functions such as protocol conversion, edge control, and device management, they solve heterogeneous interconnection challenges in industrial scenarios; through security mechanisms such as device authentication, data encryption, and intrusion detection, they safeguard the stability of production systems; through data preprocessing, aggregation, and edge AI, they enhance data value and decision-making efficiency.

In the future, with the integration of 5G, TSN, and AI technologies, IoT gateways will evolve toward greater intelligence, security, and low-carbon efficiency, becoming an indispensable "digital cornerstone" in the Industry 4.0 era. For enterprises, choosing a gateway with high reliability, strong security, and edge computing capabilities is not just an investment in hardware but also a solid foundation for future intelligent upgrades and digital transformation.