Cellular Router-Based Remote Networking: Reconstructing the Communication Foundation for Cross-Regional Collaboration

Driven by the dual forces of globalization and digital transformation, the operational boundaries of enterprises are extending from single physical spaces to three-dimensional networks spanning regions and scenarios. From nationwide store management in chain retail to distributed power plant monitoring in the energy sector, and global supply chain collaboration in manufacturing, achieving efficient interconnection of devices, systems, and personnel across different geographical locations has become a core proposition for enhancing corporate competitiveness. As a technical solution that integrates dispersed networks into a unified logical network through technological means, remote networking is emerging as a key infrastructure for digital transformation in the industrial sector, thanks to its advantages in breaking down geographical barriers, improving collaboration efficiency, and reducing operational costs. Cellular routers, as the core devices for remote networking, are redefining cross-regional communication standards in industrial scenarios through their powerful network adaptation capabilities, robust security mechanisms, and flexible deployment characteristics.

The essence of remote networking (Wide Area Network, WAN) is to connect Local Area Networks (LANs) dispersed across different geographical locations into a logically unified network environment through technologies such as Virtual Private Networks (VPNs) and Software-Defined Networking (SDN). Its core value is reflected in three aspects:

Resource Integration: Enables cross-regional data sharing, application collaboration, and device control. For example, chain enterprises can uniformly manage POS systems and inventory data across all stores nationwide through remote networking.

Efficiency Enhancement: Supports scenarios such as remote work and mobile operations and maintenance, reducing personnel travel costs. For instance, energy enterprises can remotely monitor and diagnose faults in remote power plants through remote networking.

Risk Mitigation: Improves business continuity through multi-node data backup and disaster recovery mechanisms. For example, manufacturing enterprises can synchronize production data to remote data centers in real time to prevent data loss caused by single-point failures.

From traditional dedicated line networking to modern software-defined networking, remote networking technology has undergone three key iterations:

Dedicated Line Era (Before 2000): Relied on physical dedicated lines (such as DDN and Frame Relay) for point-to-point connections, characterized by high costs and poor scalability, suitable only for industries with extremely high security requirements such as finance and telecommunications.

VPN Era (2000-2015): Built encrypted tunnels over the public internet using protocols such as IPSec and SSL, significantly reducing networking costs. However, it struggled to meet the real-time requirements of industrial scenarios due to fluctuations in public internet bandwidth.

SD-WAN Era (2015-Present): Combined software-defined networking with wide area network optimization technologies to achieve intelligent link scheduling, application priority management, and other functions. For example, an automobile manufacturer reduced the synchronization delay of design data across global R&D centers from seconds to milliseconds using SD-WAN.

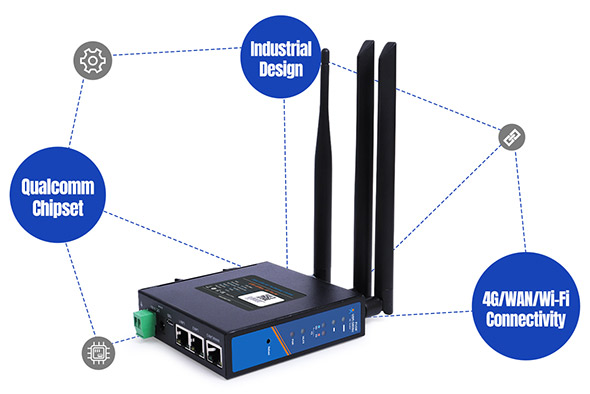

Compared to traditional enterprise-grade routers, cellular routers are specifically optimized for the demanding requirements of industrial scenarios:

Environmental Adaptability: Supports wide temperature operation from -40°C to 85°C, wide voltage input from 9-36V, and features dustproof and waterproof (IP67) and electromagnetic interference (EMC) resistance. For example, in photovoltaic power plants, cellular routers can withstand temperatures as low as -30°C and sandstorms.

Protocol Compatibility: Supports over 20 industrial protocols such as Modbus TCP, OPC UA, and Profinet, enabling seamless integration with devices such as PLCs, sensors, and robots. For instance, in smart manufacturing workshops, cellular routers can simultaneously connect Siemens S7-1200 PLCs and KUKA robot controllers.

Security Protection: Integrates firewalls, intrusion detection, and data encryption (AES-256) functions, meeting the requirements of Level 3 of the Cybersecurity Classification Protection 2.0. For example, in power monitoring systems, cellular routers communicate with master station systems through VPN tunnels to prevent data tampering.

Cellular routers achieve remote networking through the following technologies:

VPN Tunneling Technology: Supports protocols such as IPSec, OpenVPN, and L2TP to build end-to-end encrypted channels. For example, the USR-G809s cellular router adopts a dual-VPN redundancy design, automatically switching to a backup link when the primary link fails to ensure uninterrupted monitoring data transmission.

Intelligent Traffic Scheduling: Dynamically allocates bandwidth based on parameters such as application priority and link quality. For example, in video surveillance scenarios, cellular routers can prioritize the transmission of high-definition streams from 4K cameras while limiting bandwidth usage for non-critical devices.

Edge Computing Capabilities: Built-in with lightweight operating systems, supporting Python scripting and local data processing. For example, in smart warehousing scenarios, cellular routers can perform preliminary data cleaning on data collected by RFID readers before uploading it to the cloud, reducing cloud computing load by 30%.

In an automobile welding workshop, cellular routers achieve the following functions through remote networking:

Data Acquisition: Connect to welding robot controllers via RS485 interfaces to collect parameters such as current, voltage, and welding time in real time, and transmit the data back to the MES system via 4G networks.

Device Control: Support millimeter-level collaboration between AGV trolleys and robotic arms through WiFi 6 networks, ensuring welding accuracy of ±0.1mm for car bodies.

System Collaboration: Divide production line subnets using VLAN functionality to avoid broadcast storms while ensuring the security of R&D data through VPN-encrypted channels.

After deploying the USR-G809s, a home appliance enterprise reduced production line data acquisition delay from seconds to milliseconds, improved Overall Equipment Effectiveness (OEE) by 18%, and decreased annual maintenance costs by RMB 2 million.

In a photovoltaic power plant in Qinghai, cellular routers solve the following challenges through remote networking:

Private Network Encrypted Transmission: Encrypt and transmit electricity meter data and environmental monitoring information back to the control center through an APN private network, achieving financial-grade data transmission security.

Dual-Link Backup: 4G and WiFi 6 networks serve as backups for each other, automatically switching when a single link fails to ensure continuous communication.

Remote Operations and Maintenance: Operations and maintenance personnel can remotely upgrade firmware and configure parameters through a cloud platform, reducing on-site inspection frequencies.

After adopting this solution, the power plant reduced annual operations and maintenance costs by 40% and increased data acquisition completeness to 99.9%.

In a smart street project in Hangzhou, cellular routers achieve the following functions through remote networking:

Low-Power Design: Support timed on/off functionality and, when paired with solar power systems, consume less than 10 kWh of electricity per node annually.

Large-Scale Networking: Expand to thousands of nodes through Mesh self-organizing network technology, covering entire urban areas.

Open Protocol Support: Compatible with IoT protocols such as MQTT and CoAP, enabling seamless integration with urban brain platforms.

After project deployment, the response time for streetlight failures was reduced from 2 hours to 10 minutes, achieving annual energy savings of over 30%.

In JD.com's Asia No. 1 warehouse, cellular routers achieve the following functions through remote networking:

Device Interconnection: Connect RFID readers, cameras, AGV trolleys, and other devices through WiFi 6 to enable real-time cargo tracking and automated inventory management.

Edge Computing: Perform target detection on video streams locally and upload only abnormal events (such as cargo falls) to the cloud, reducing bandwidth usage by 70%.

Hybrid Cloud Management: Interface with Alibaba Cloud IoT platforms through VPN tunnels to enable device status monitoring and remote configuration.

After deployment, the warehouse improved sorting efficiency by 40% and reduced labor costs by 25%.

In a multinational manufacturing enterprise, cellular routers achieve the following functions through remote networking:

Secure Access: Employees remotely access the corporate intranet through SSL VPNs, with two-factor authentication (password + SMS verification code) for identity verification.

Application Optimization: Prioritize bandwidth for critical applications such as ERP and CRM using SD-WAN technology to ensure a seamless remote work experience.

Data Backup: Automatically synchronize employee local files to remote data centers to prevent data loss.

After adopting this solution, the enterprise improved remote work efficiency by 35% and reduced travel costs by 50%.

Implementing remote networking requires the following steps:

Requirements Analysis: Clarify key parameters such as business scenarios (e.g., real-time monitoring, remote control), data volume (e.g., 100 MB per second), and latency requirements (e.g., <50 ms).

Topology Design: Select star, ring, or mesh topologies based on the scenario. For example, mesh topologies are used in distributed energy scenarios to improve network fault tolerance.

Device Selection: Choose cellular routers that support required protocols (e.g., Modbus TCP), interfaces (e.g., RS485), and protection levels (e.g., IP67).

Taking the USR-G809s as an example, the deployment process is as follows:

Hardware Installation: Secure the router inside a control cabinet using DIN rails and connect power, antennas, network cables, etc.

Network Configuration: Set VPN parameters (e.g., IPSec pre-shared keys), VLAN divisions, firewall rules, etc., in the web management interface.

Application Integration: Interface with systems such as MES and SCADA through API interfaces to enable automatic data acquisition and remote device control.

During the operations and maintenance phase, the following aspects require focused attention:

Real-Time Monitoring: Monitor router CPU utilization, bandwidth usage, and other indicators through the SNMP protocol, setting threshold alerts.

Fault Troubleshooting: Use log analysis tools to locate the causes of network interruptions, such as analyzing VPN tunnel abnormalities through Wireshark packet captures.

Performance Optimization: Adjust QoS strategies based on business changes, such as prioritizing PLC communication bandwidth during peak production seasons.

As 5G, AI, edge computing, and other technologies mature, cellular router-based remote networking will evolve in the following directions:

5G + Cellular Routers: Leverage 5G's low latency (<1 ms) and high reliability (99.999%) to enable ultra-real-time scenarios such as motion control and remote surgery.

AI-Driven Self-Optimization: Use machine learning models to predict network traffic peaks and automatically adjust bandwidth allocation strategies.

TSN and WiFi 6 Integration: Build deterministic networks in industrial settings to ensure time delay jitter of <1 μs for multi-device collaboration.

From smart manufacturing to smart cities, and from energy management to remote work, cellular router-based remote networking is redefining communication paradigms in industrial scenarios with its core advantages of "wireless connectivity, high bandwidth, low latency, and robust security." It is not merely a tool for connecting devices but an ecological hub that drives data flow and empowers intelligent decision-making. As technology continues to evolve, this communication powerhouse is poised to unlock even greater value, propelling global industry toward higher levels of digitalization and intelligence.