Driven by the wave of Industry 4.0 and intelligent manufacturing, traditional industrial equipment is undergoing a profound transformation from "single-function" to "intelligent interconnection." As the core carrier of industrial automation and edge computing, the PUSR embedded industrial PC EG828, with its high performance, high reliability, and open ecosystem, has become the "industrial brain" connecting the physical and digital worlds. This article will comprehensively analyze the core value of this product from four dimensions: technical essence, functional characteristics, application scenarios, and competitive advantages.

1. What is an Embedded Industrial PC?

An embedded industrial computer is a computing device specifically designed for industrial environments. Its core characteristics include:

Environmental Adaptability: It adapts to extreme conditions such as high temperatures in workshops, low temperatures outdoors, and electromagnetic interference through structural optimizations like wide-temperature design (-10℃~70℃), vibration resistance, dust prevention, and moisture resistance.

Stability Priority: It adopts fanless cooling and low-power design, supporting 7×24-hour continuous operation with a failure rate much lower than that of commercial PCs.

Compact Integration: It is small in size (e.g., the embedded industrial PC EG828 measures 230×219×84mm) and can be embedded inside equipment, saving space and simplifying wiring.

Customized Functionality: It supports multi-protocol compatibility (e.g., Modbus, MQTT) and multi-interface expansion (RS232/RS485/CAN/Ethernet), meeting the needs of industrial automation, data acquisition, motion control, and other scenarios.

In intelligent manufacturing production lines, embedded industrial computers need to simultaneously process sensor data, control PLC equipment, run AI algorithms, and upload data to the cloud. Their performance and reliability directly impact production efficiency. For example, a certain automotive parts factory improved the accuracy of equipment failure prediction to 98% and reduced downtime by 40% by deploying the embedded industrial PC EG828.

2. Core Functions of the Embedded Industrial PC EG828: From Edge Computing to AI Empowerment

2.1 High-Performance Computing Core

The embedded industrial PC EG828 is equipped with a Rockchip RK3568 quad-core 64-bit Cortex-A55 processor with a main frequency of up to 2.0GHz, coupled with 4GB DDR4 memory and 32GB eMMC storage, building an industrial-grade computing platform. Its built-in ARM G52 2EE GPU supports 4K60fps video decoding and 1080P100fps encoding, enabling it to simultaneously handle multiple video streams such as industrial vision inspection and high-definition surveillance.

Typical Application:

In an electronics manufacturing production line, the embedded industrial PC EG828 connects to a 4K industrial camera via an HDMI 2.0 interface to analyze PCB board soldering defects in real-time, achieving a detection speed of 30 frames per second, which is three times more efficient than traditional solutions.

2.2 Breakthrough in AI Computing Power: Empowered by 1.0TOPS NPU

The embedded industrial PC EG828 integrates an NPU neural network processor with 1.0TOPS INT8 computing power, supporting mainstream AI frameworks such as Caffe and TensorFlow Lite. It can run edge AI models such as facial recognition, defect detection, and voice interaction.

Case Verification:

In a smart grid project, the AI quality inspection module of the embedded industrial PC EG828 was used to detect cracks in transmission line insulators, achieving an identification accuracy of 99.2% and a false detection rate of less than 0.5%, which is 10 times more efficient than manual inspections.

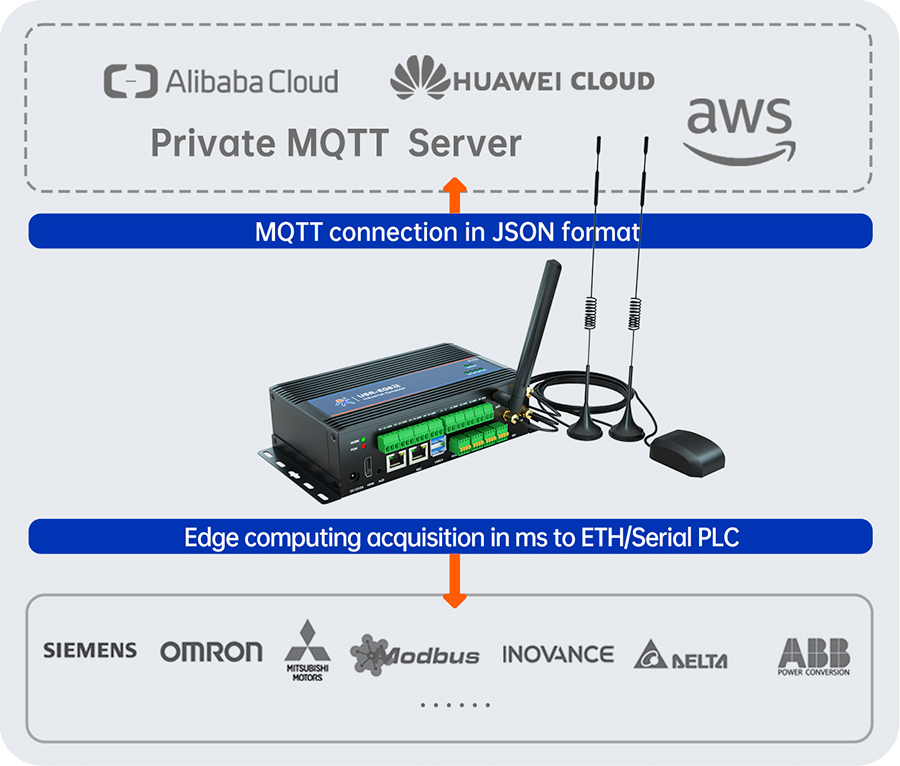

2.3 Industrial Protocol Compatibility and Data Acquisition

The device is built with the "M300" edge service, supporting industrial protocols such as Modbus TCP/RTU, OPC UA, and MQTT. It can directly interface with PLCs from brands such as Siemens and Omron, enabling millisecond-level data acquisition and local联动(local interaction).

Scenario Example:

In the control of a chemical reaction kettle, the embedded industrial PC EG828 simultaneously connects to over 200 temperature and pressure sensors via an RS485 interface, controlling data upload delays within 50ms to ensure real-time adjustment of process parameters.

2.4 Multimodal Interface Expansion

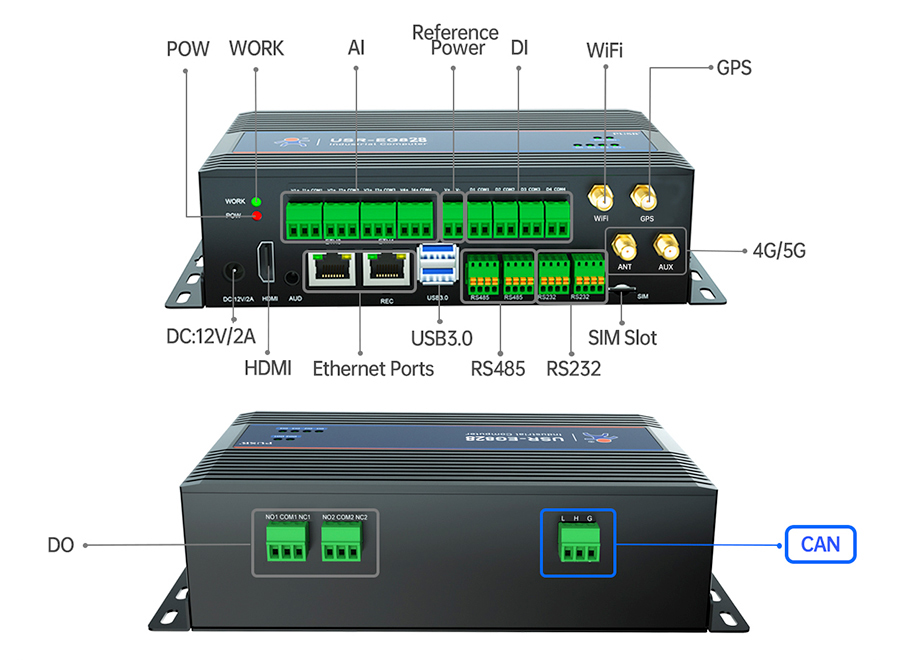

The embedded industrial PC EG828 offers a rich set of hardware interfaces:

Communication Interfaces: 2 RS232 ports, 2 RS485 ports, CAN bus, and 2 Gigabit Ethernet ports, compatible with sensors, frequency converters, and other equipment.

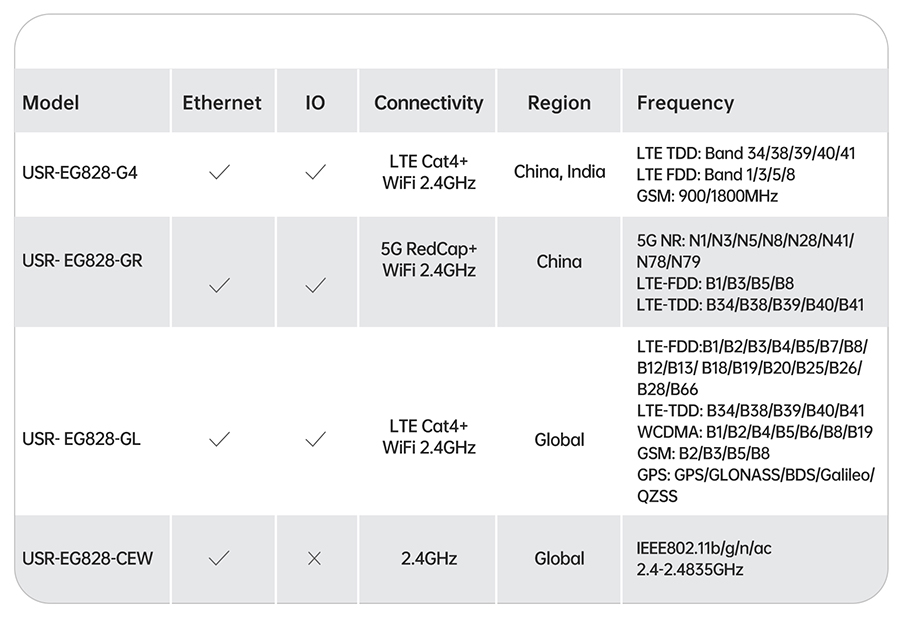

Wireless Communication: 4G/5G RedCap (optional), 2.4GHz WiFi, and GPS/Beidou positioning, meeting the needs of mobile scenarios and remote networking.

Display Interfaces: HDMI 2.0 (4K output), eDP, MIPI, and LVDS, supporting multi-screen displays and industrial touchscreens.

Application Scenario:

In an AGV logistics robot, the embedded industrial PC EG828 receives lidar data via a CAN bus, uploads it to a cloud-based scheduling system via WiFi, and simultaneously displays task instructions via an HDMI interface, achieving integrated control of navigation, obstacle avoidance, and path planning.

3. ARM Architecture: The Perfect Balance of Low Power Consumption and High Energy Efficiency

The embedded industrial PC EG828 is also an ARM industrial PC. What are the benefits of the ARM architecture?

3.1 Core Advantages of ARM Architecture

Outstanding Energy Efficiency: The Cortex-A55 architecture adopts dynamic voltage and frequency scaling (DVFS), reducing power consumption by 60% compared to x86 architectures, making it suitable for fanless cooling industrial environments.

Real-Time Performance Guarantee: The deterministic execution characteristics of the ARM architecture ensure millisecond-level response to industrial control instructions.

Open Ecosystem: The Linux+ARM combination supports Docker containerized deployment, enabling developers to quickly develop applications through low-code platforms like Node-Red.

3.2 Comparison with x86 Architecture

Dimension | ARM Architecture (EG828) | x86 Architecture |

Power Consumption | 10W~15W (typical load) | 35W~65W (same performance level) |

Temperature Adaptability | -10℃~70℃ | 0℃~50℃ (requires additional cooling) |

Startup Speed | Within 5 seconds (Linux system) | Over 30 seconds (Windows system) |

Cost | Lower (no licensing fees) | Higher (Intel/AMD chips) |

Conclusion: The ARM architecture offers better cost-effectiveness in industrial edge scenarios, especially for embedded applications sensitive to power consumption and size.

4. Linux System Development: Open Ecosystem Empowering Industry Customization

4.1 System Support and Development Flexibility

The embedded industrial PC EG828 comes pre-installed with the Ubuntu 20.04 LTS system, supporting:

Visual Development: Quickly build industrial HMI interfaces through the Qt framework.

Containerized Deployment: Docker supports microservice architectures, enabling independent operation of AI models, databases, and control logic.

Multi-System Compatibility: Optional Android system, compatible with interactive devices such as smart vending machines and medical touchscreens.

4.2 Typical Application Scenarios

Industrial Control: Implement PID control algorithms with an accuracy of ±0.1% based on the Linux real-time kernel (PREEMPT-RT).

Medical Image Analysis: Deploy AI-assisted diagnostic modules on the Linux system to locally preprocess CT/MRI images, reducing diagnosis time from 15 minutes to 2 minutes.

Energy Management: Develop energy consumption analysis algorithms through Python scripts to monitor factory electricity usage in real-time and generate optimization reports.

5. Video AI Models: Full-Link Coverage from Detection to Decision-Making

5.1 Functional Implementation Path

The EG828 supports lightweight AI frameworks such as ONNX Runtime and TensorFlow Lite and can deploy the following models:

Object Detection: YOLOv5-tiny (identifies workpiece positions on production lines with an accuracy of 95%).

Behavior Analysis: OpenPose (monitors whether operator actions comply with regulations).

Anomaly Detection: LSTM neural network (predicts equipment vibration data trends and provides 72-hour advance warning of failures).

5.2 Industry Implementation Cases

Smart Retail: Deploy facial recognition payment models in unmanned vending cabinets, reducing cargo loss rates by 80%.

Intelligent Transportation: Serve as a vehicle gateway, analyzing road signs through video AI to support autonomous driving decisions.

Security Monitoring: Deploy smoke and fire detection models in chemical parks, with a false alarm rate of less than 0.1%.

6. Five Reasons to Choose the Embedded Industrial PC EG828

6.1 Industrial-Grade Reliability

Certified to the MIL-STD-810G standard, it is shock-resistant and salt-spray-resistant, suitable for extreme environments such as offshore platforms and mines.

6.2 Full-Scenario Coverage

From data acquisition and edge computing to AI inference, a single device meets the full-link needs of industrial automation.

6.3 Rapid Development Support

Provides complete API documentation and SDKs, allowing developers to call standardized interfaces such as GPIO and AI computing power, lowering the threshold for secondary development.

6.4 Long-Term Service Guarantee

PUSR offers a 5-year warranty and remote OTA upgrade services, ensuring technical compatibility throughout the device's lifecycle.

6.5 Cost Advantage

Compared to x86 industrial computers, the embedded industrial PC EG828 reduces overall costs by 40% and eliminates the need for Windows system licensing fees.

7. The "Smallest Complete Unit" of Industrial Intelligence

The PUSR embedded industrial PC EG828, with its core of "ARM architecture + Linux ecosystem + AI computing power," redefines the technological boundaries of industrial controllers. Whether for rapidly deployable standard solutions or customized industry applications, the EG828 can serve as the core engine for enterprise intelligent transformation with its high performance, high reliability, and open ecosystem.

Experience it now: Visit the PUSR official website to access technical documentation and industry solutions, and make the embedded industrial PC EG828 the intelligent hub for your industrial scenarios.