At the dawn of Industry 4.0 sweeping across the globe, core pain points in enterprise digital transformation are gradually emerging: How to achieve efficient interconnection of heterogeneous devices? How to ensure the security of data transmission? How to lower the technical barriers for system integration? PUSR's open source API gateway USR-EG118 provides a groundbreaking solution for the industrial IoT field with its innovative concept of "open architecture + modular design."

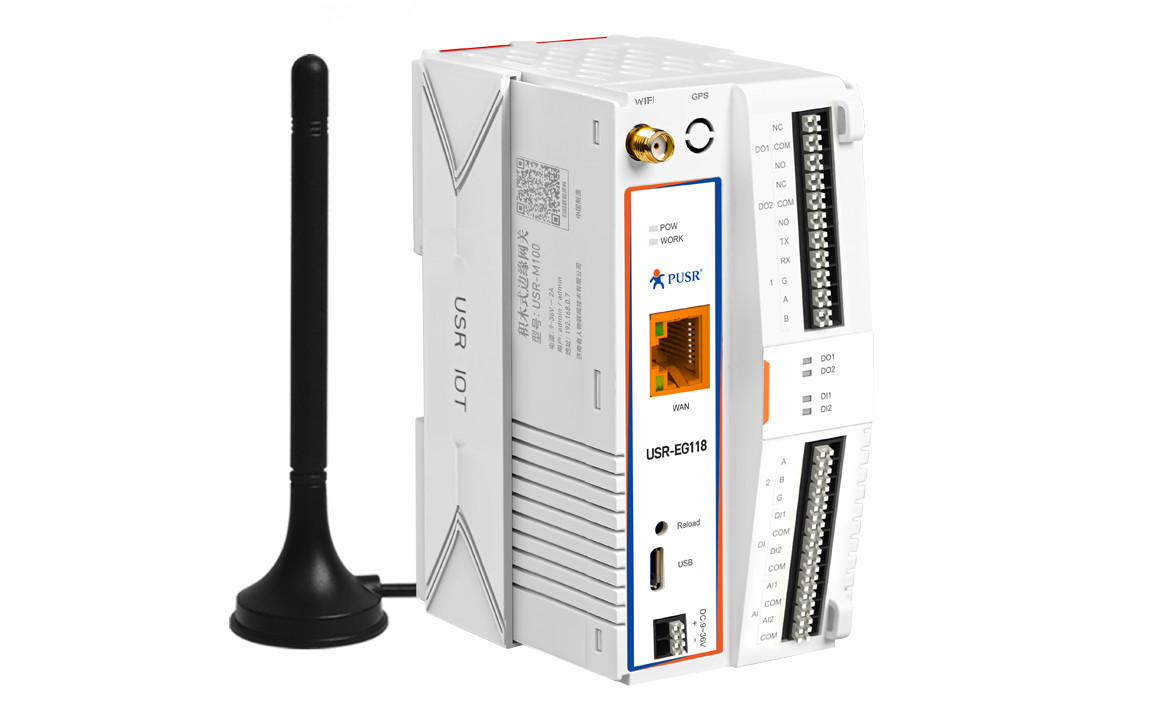

This open-source hardware based on the ESP32 chip not only supports dual development modes of Arduino IDE and ESP-IDF but also redefines the technical standards for industrial gateways through core functions such as AWS cloud platform integration and Modbus protocol conversion.

1. The Essence of Open Source API Gateway Technology: The Key to Breaking Data Silos

The essence of an open source API gateway is to construct an open industrial data transit station, with its core value lying in enabling seamless communication between devices using different protocols through standardized interfaces. In traditional industrial scenarios, devices such as PLCs, sensors, and actuators often adopt proprietary protocols like RS485, Modbus, and CAN, leading to high system integration costs. The open source API gateway USR-EG118 can simultaneously handle bidirectional conversion between Internet protocols such as TCP/IP, MQTT, and HTTP and industrial protocols through its built-in protocol conversion engine, forming a three-tier data pathway of "device - gateway - cloud."

Taking the application in a sewage treatment plant as an example, the open source API gateway EG118 can simultaneously connect:

PH sensors accessed via RS485 interfaces (Modbus RTU protocol)

Flow meters accessed via Ethernet (Modbus TCP protocol)

Frequency converters accessed via WiFi (OPC UA protocol)

Mobile inspection terminals accessed via BLE

All device data is uniformly processed by the gateway and uploaded to AWS IoT Core using the MQTT protocol, enabling real-time monitoring and intelligent control. This protocol transparency processing capability allows enterprises to complete digital upgrades without replacing existing equipment.

2. Technical Advantages of the Open Source API Gateway EG118: Redefining Industrial Gateway Standards

2.1 Breakthrough in Hardware Performance

Equipped with an ESP32-WROVER-E dual-core processor (240MHz main frequency) and a luxurious storage configuration of 8MB PSRAM and 4MB SPI Flash, the open source API gateway EG118 achieves industry-leading data throughput capabilities. Measured data shows that it can stably process 2,000 device instructions per second, with latency controlled within 50ms, meeting the real-time requirements of smart manufacturing scenarios.

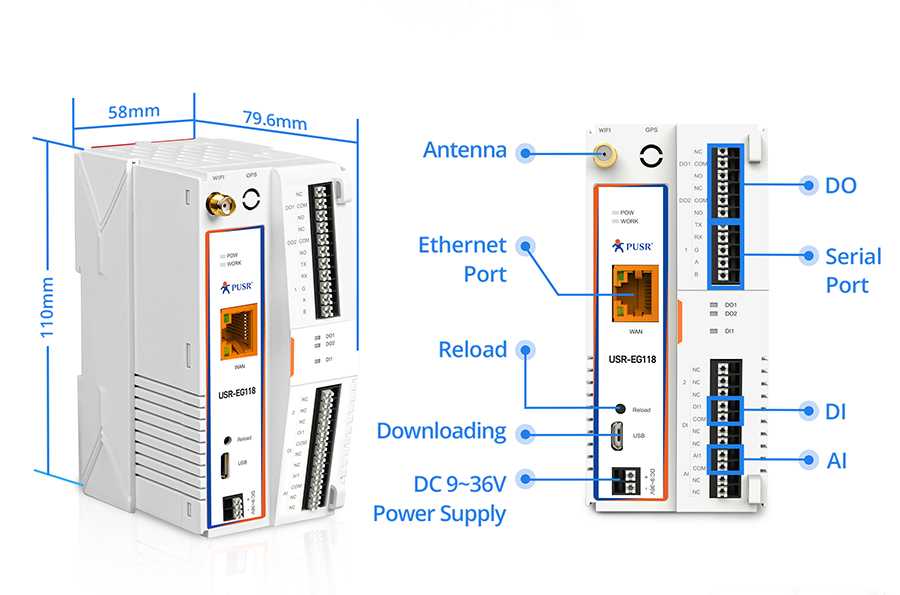

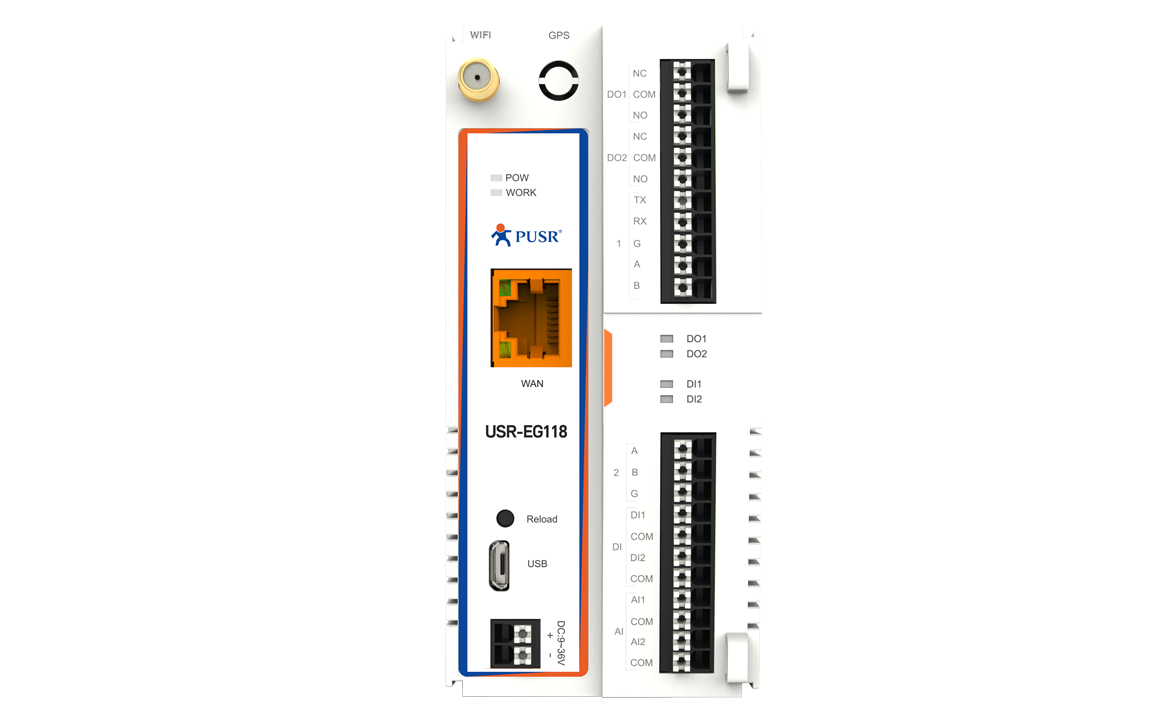

The hardware interface design fully reflects industrial-grade considerations:

Isolated RS485 interfaces (15kV ESD protection)

Optocoupler-isolated digital inputs (DI)

12-bit ADC analog inputs (AI)

Industrial-grade Ethernet interfaces (supporting POE power supply)

Dual-band WiFi (2.4G/5G) and BLE5.0 wireless modules

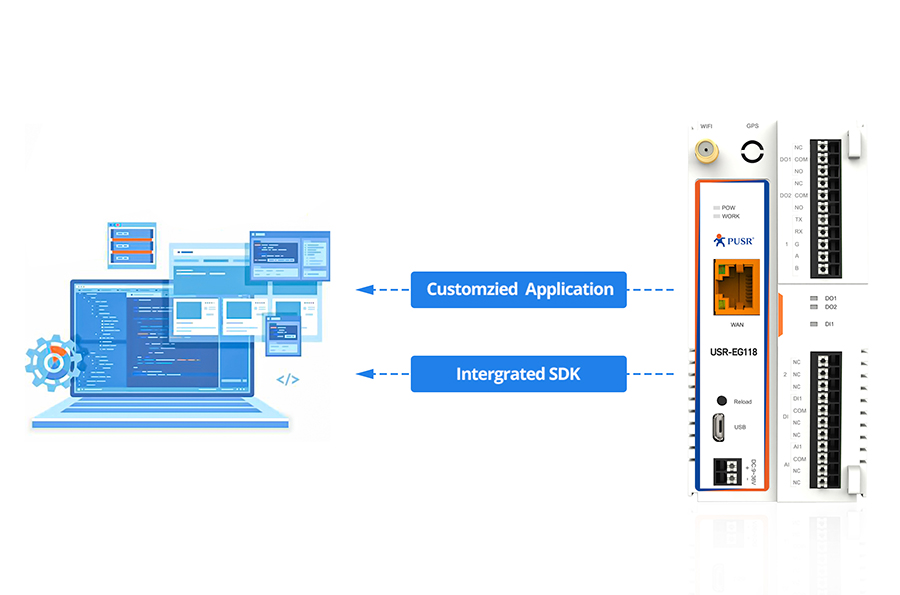

2.2 Revolutionary Innovation in the Development Ecosystem

As the first industrial gateway to support Arduino IDE, the open source API gateway EG118 significantly lowers the barriers to embedded development. Developers can quickly implement function development using Arduino syntax, similar to C language, without mastering complex RTOS system programming. The official library files provided cover:

Modbus master/slave protocol stacks

AWS IoT device SDK

MQTT client implementation

OTA firmware upgrade modules

Web server frameworks

Typical development processes show that function realization only takes 3 hours from environment setup:

Install Arduino IDE and add support for the ESP32 development board

Import core libraries such as USR_IO and AWS_IOT

Modify device parameters and cloud platform configurations in the Demo

Burn firmware using a USB-to-TTL downloader

2.3 Deep Integration of Cloud-Edge Collaboration

In response to the cloud management needs of industrial scenarios, the open source API gateway EG118 provides a complete AWS integration solution. Through pre-configured AWS IoT Core connection templates, users only need to modify authentication credentials to achieve:

Device Shadow synchronization

Rules Engine triggering

Greengrass edge computing

S3 bucket data archiving

A practice in a solar power plant shows that after adopting USR-EG118, the data upload latency of photovoltaic inverters decreased from 3 seconds to 200ms, and cloud analysis efficiency improved by 40%.

3. Core Function Analysis: Six Capability Matrices for Industrial IoT

3.1 Multi-Protocol Conversion Engine

Supports 12 industrial protocols such as Modbus RTU/TCP, OPC UA, CANopen, and BACnet, enabling:

Transparent transmission of serial devices to TCP/IP networks

Data mapping between devices using different protocols

Custom parsing and encapsulation of protocol messages

3.2 Edge Computing Container

Built-in lightweight Lua scripting engine, supporting the execution of the following on the gateway side:

Data preprocessing (filtering, normalization)

Local control strategies (PID regulation, threshold alarms)

Customization of protocol conversion rules

Offline caching and breakpoint resumption

3.3 Security Protection System

Constructs a five-layer security protection:

Hardware level: Built-in encryption engine in the ESP32 chip (AES-256/SHA-2)

Transport layer: TLS 1.3 encrypted channels

Access control: JWT-based API authentication

Device authentication: X.509 digital certificates

Firmware security: Secure Boot and encrypted upgrades

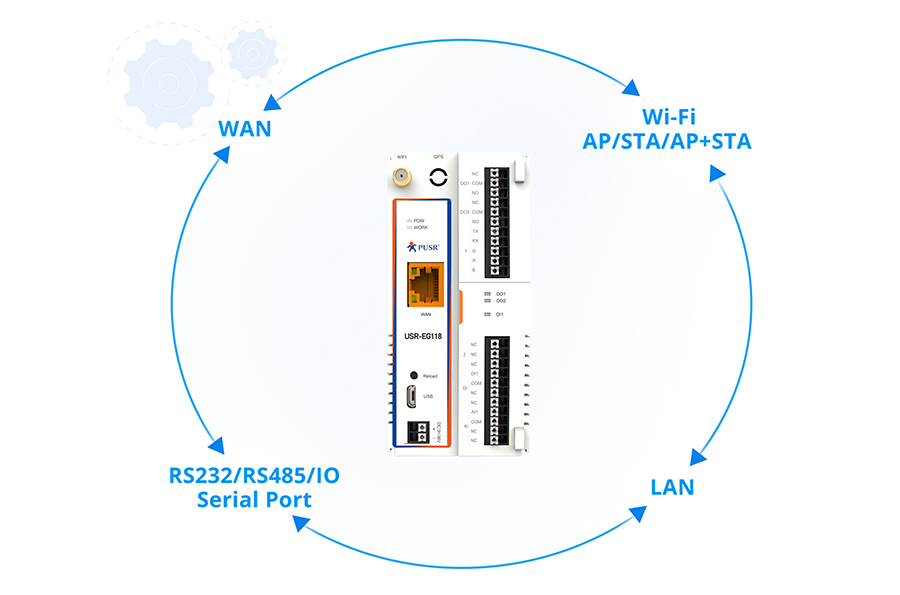

3.4 Wireless Networking Solutions

Provides three industrial-grade wireless networking modes:

AP mode: Serving as a hotspot for mobile terminal access

STA mode: Connecting to existing WiFi networks

Mesh self-organizing networks: Supporting multi-node relay transmission

In agricultural irrigation scenarios, Mesh networking can extend signal coverage to 2 kilometers, addressing wireless communication blind spots in farmland.

3.5 Remote Management Platform

The accompanying PUSR Cloud platform provides:

Bulk device configuration

OTA firmware upgrades

Operating log analysis

Fault warning notifications

Performance dashboard display

3.6 Industrial Interface Expansion

Reserves 20 programmable IOs, supporting:

Digital inputs (dry contacts/wet contacts)

Digital outputs (relays/NPN)

Analog inputs (0-10V/4-20mA)

Pulse counting inputs

4. Who Needs the Open Source API Gateway EG118?

4.1 Industrial System Integrators

Demand: Rapidly retrofitting legacy equipment for networking

Case: An automotive parts manufacturer connected 200 injection molding machines to an MES system using the open source API gateway EG118, reducing the retrofitting cycle from 6 months to 2 months

4.2 Equipment Manufacturers

Demand: Adding IoT capabilities to products

Case: After integrating the open source API gateway EG118, a water pump manufacturer increased product added value by 30%, with remote operation and maintenance revenue accounting for 15%

4.3 Smart City Operators

Demand: Building city-level IoT infrastructure

Case: A smart park adopted the open source API gateway EG118 as an edge computing node, enabling unified management of subsystems such as lighting, air conditioning, and security

4.4 Scientific Research and Educational Institutions

Demand: IoT teaching and experimental platforms

Case: A university incorporated the open source API gateway EG118 into its IoT curriculum, allowing students to complete the entire process from hardware programming to cloud deployment

5. Typical Application Scenarios: Value Verification from Laboratory to Production Line

5.1 Intelligent Monitoring of Sewage Treatment

At a sewage treatment plant in Jiangsu, the open source API gateway EG118 connects:

Liquid level meters (RS485)

Dissolved oxygen meters (Modbus TCP)

Blowers (OPC UA)

Video surveillance (ONVIF)

Through a water quality prediction model trained with AWS SageMaker, dynamic adjustment of chemical dosing is achieved, reducing chemical consumption by 18%.

5.2 Precision Control of Agricultural Irrigation

At a cotton planting base in Xinjiang, the following are deployed:

Soil moisture sensors (LoRa)

Meteorological stations (4G)

Solenoid valves (RS485)

Solar power supply systems

The edge computing function of the open source API gateway EG118 executes irrigation strategies, achieving a water-saving rate of 35% and a 12% increase in cotton yield per unit area.

5.3 Optimization of Photovoltaic Power Plant Operation and Maintenance

At a 50MW photovoltaic power plant in Qinghai, the following are adopted:

Inverters (CAN bus)

Combiner boxes (Modbus RTU)

Meteorological stations (RS232)

Drone inspections (5G)

Through protocol conversion and data aggregation by the gateway, real-time optimization of power generation efficiency is achieved, with a 2.3 percentage point increase in the PR (Performance Ratio) value.

6. Six Reasons to Choose the Open Source API Gateway EG118

6.1 Technical Autonomy and Controllability

Fully open-source hardware design and software code support secondary development by enterprises, avoiding lock-in by a single supplier.

6.2 Cost-Effectiveness

Compared to similar products, the hardware cost of the open source API gateway EG118 is reduced by 40%, and the development cycle is shortened by 60%.

6.3 Industrial-Grade Reliability

Passes -40℃~85℃ wide temperature tests and EMC Level 3 certification, with an MTBF (Mean Time Between Failures) of 50,000 hours.

6.4 Ecosystem Integrity

Provides full-chain support from hardware development to cloud deployment, including:

3D printed enclosure design files

Circuit schematics and PCB layouts

Complete technical documentation systems

7x24-hour technical support

6.5 Continuous Evolution Capability

Based on Arduino's modular design, it supports the realization of the following through expansion boards:

LoRa wireless communication

4G/5G cellular networks

Zigbee 3.0 networking

Beidou/GPS positioning

6.6 Global Certification System

Obtains international certifications such as CE, FCC, and RoHS, supporting exports to European and American markets.

Ushering in an Open Era for Industrial IoT

The emergence of USR-EG118 marks a paradigm shift in industrial gateways from "black box devices" to "open platforms." Its core value lies not only in leading technical parameters but also in constructing an extensible, customizable, and evolvable industrial IoT ecosystem. For enterprises seeking to take the initiative in digital transformation, USR-EG118 provides not just a hardware product but an open gateway to Industry 4.0. When the spirit of open source meets industrial demands, a silent technological revolution is underway.