PUSR Industrial Ethernet Switch USR-ISG: Analysis of Core Equipment in Industrial Networks

Under the impetus of Industry 4.0 and the trend of intelligent manufacturing, industrial networks, serving as the "nerve center" connecting equipment, data, and systems, directly impact production efficiency and safety through their stability and reliability. PUSR's Industrial Ethernet Switch USR-ISG has emerged as an indispensable core device in industrial settings, thanks to its military-grade design, high protection performance, and intelligent management functions.

1. Industrial Ethernet Switch: The "Bridge" and "Guardian" of Industrial Networks

Industrial Ethernet switches are network devices specifically designed for harsh industrial environments. Their core function is to enable interconnection between industrial equipment (such as PLCs, sensors, robots, etc.) and control systems through high-speed, stable data transmission. Compared to traditional commercial switches, industrial switches require stronger anti-interference capabilities, wider temperature adaptability, and redundant designs to cope with complex scenarios involving electromagnetic interference, vibrations, dust, extreme temperatures, and more.

Core Values of Industrial Ethernet Switch ISG:

Data Transmission Hub: Supports high-speed, low-latency data exchange to ensure precise transmission of real-time control instructions and monitoring data.

Network Reliability Assurance: Avoid network interruptions caused by single points of failure through technologies such as ring redundancy and link aggregation.

Environmental Adaptability: Adapts to a wide temperature range from -40℃ to 75℃, resisting vibrations, humidity, and corrosive gases in industrial settings.

2. Aluminum Alloy Enclosure + DIN Rail Mounting + Industrial-Grade Temperature Design: Built for Harsh Environments

The Industrial Ethernet Switch ISG features a full aluminum alloy enclosure combined with a DIN rail mounting design, balancing heat dissipation performance with installation convenience:

Advantages of Aluminum Alloy Enclosure:

Efficient Heat Dissipation: Metal materials accelerate heat conduction, preventing component aging caused by high temperatures.

Electromagnetic Interference (EMI) Shielding: Shields against external electromagnetic interference, ensuring stable data transmission.

Durable and Robust: Resistant to impacts and corrosion, suitable for vibration-prone industrial sites (such as machinery manufacturing and rail transit).

DIN Rail Mounting:

Supports standard DIN35mm rails, enabling quick deployment inside control cabinets, saving space, and facilitating maintenance.

Suitable for compact spaces (such as power cabinets and automated production lines).

Industrial-Grade Temperature Design:

Operating temperature range extends from -40℃ to 75℃, covering extremely cold (e.g., Arctic wind farms) and hot (e.g., steel mills) environments.

Built-in temperature sensors and intelligent heat dissipation systems automatically adjust fan speeds to extend device lifespan.

Typical Application Industries:

Energy and Power: Outdoor or high-temperature environments such as wind power, photovoltaic, and substations.

Rail Transit: Train control systems for subways and high-speed rail.

Intelligent Manufacturing: High-temperature production lines such as automobile welding and stamping.

3. Industrial Lightning Protection 6000V: The "First Line of Defense" for Network Security

Industrial sites often face overvoltage threats such as lightning strikes and static electricity. The 6000V industrial lightning protection design of the Industrial Ethernet Switch ISG provides protection through the following mechanisms:

Three-Level Lightning Protection:

Power Port: 6000V lightning protection module to resist induced lightning and direct lightning strikes.

Network Port: Built-in Gas Discharge Tubes (GDTs) and TVS diodes to limit transient overvoltages.

Lightning Protection Effects:

Complies with IEC 61000-4-5 standards, capable of withstanding an impulse current of 8/20μs waveform, 6kV/3kA.

Prevents equipment damage and data loss caused by lightning strikes.

Applicable Environments:

Outdoor Base Stations: Communication towers and photovoltaic inverters in wind farms.

Mining and Metallurgy: Open-pit mining equipment and blast furnace control systems.

Traffic Signal Control: Expressway ETC systems and urban traffic lights.

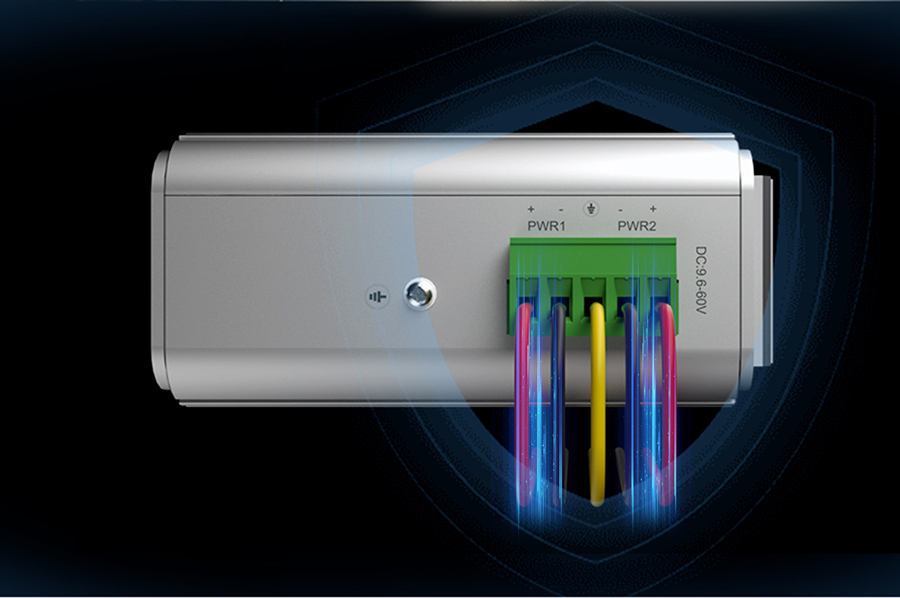

4. Multiple Power Protections + Universal GB POE: Safe Power Supply, Avoiding "Burnout" Risks

The power system of the Industrial Ethernet Switch ISG addresses industrial power supply pain points through multiple protection mechanisms and Power over Ethernet (PoE) functionality:

Power Protection Technologies:

Overvoltage/Undervoltage Protection: Automatically cuts off abnormal voltages to prevent component breakdown.

Reverse Connection Protection: Prevent short circuits caused by reversed power polarity.

Surge Suppression: Suppresses transient pulses on power lines to extend device lifespan.

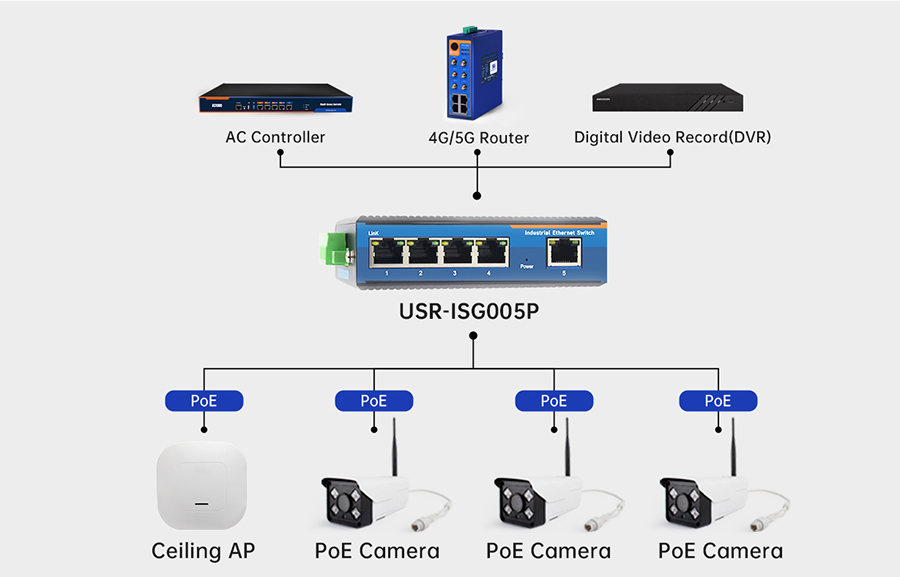

Universal GB POE:

Supports IEEE 802.3af/at standards, with a maximum output of 30W per port, compatible with GB-compliant devices.

Intelligent power distribution prevents equipment burnout caused by power overload.

Business Benefits:

Reduced Maintenance Costs: Minimizes equipment replacement and downtime losses caused by power failures.

Simplified Cabling: Transmits data and power simultaneously over network cables, saving on cabling and construction costs.

Enhanced Safety: Avoid fire risks caused by voltage mismatches in non-standard PoE devices.

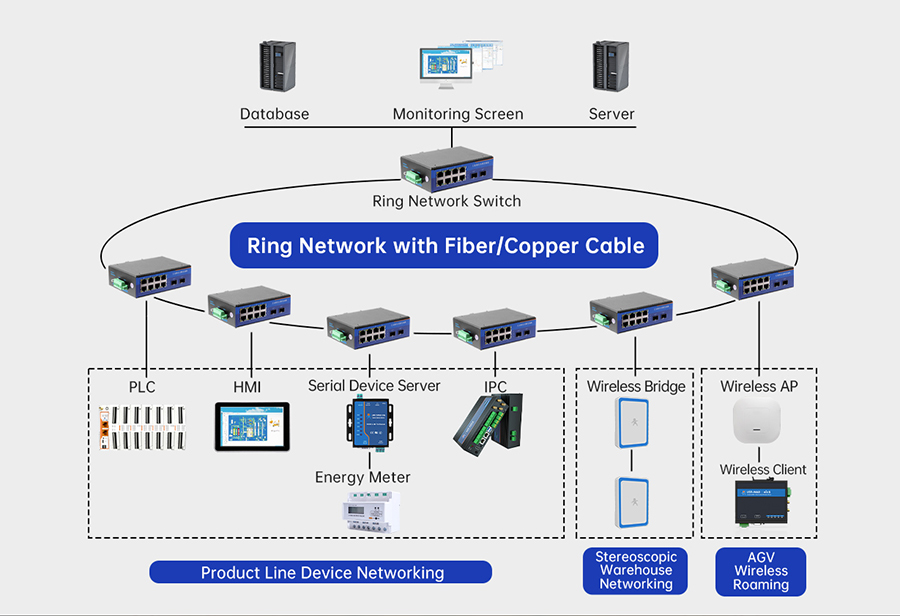

5. Ring Redundancy: Zero Communication Interruptions, Ensuring Continuity of Critical Operations

The Industrial Ethernet Switch ISG supports fast ring redundancy protocols (such as STP/RSTP/ERPS), constructing self-healing networks:

Redundancy Mechanism:

When the primary link fails, the backup link automatically switches within 20ms to ensure uninterrupted communication.

Supports various topologies such as dual primary rings and single rings to adapt to different scenario requirements.

Typical Application Industries:

Urban Rail Transit: Train signaling systems require millisecond-level responses, with redundancy designs preventing accidents.

Petrochemical Industry: Pipeline monitoring networks require 7×24 operation, with redundancy ensuring data integrity.

Smart Cities: Critical infrastructure such as traffic monitoring and environmental monitoring.

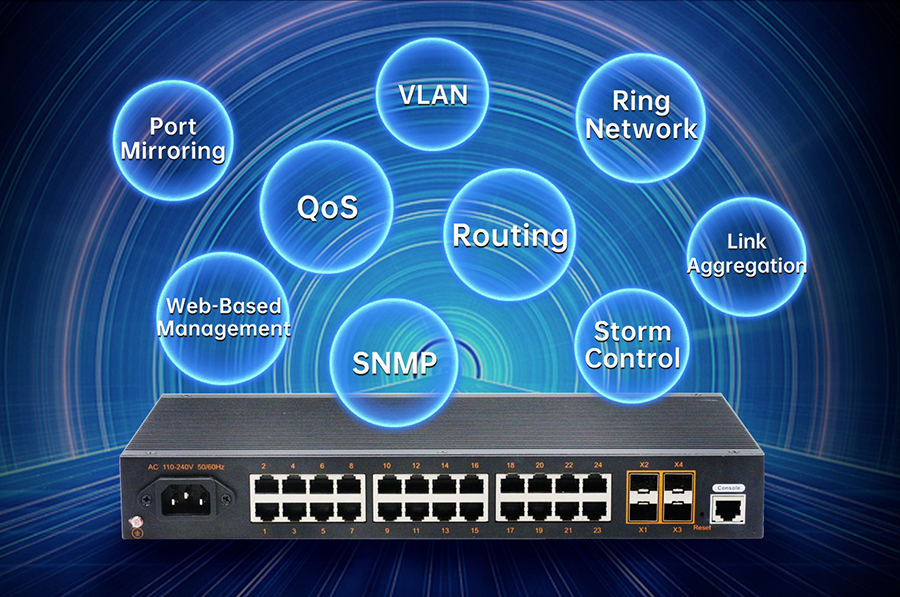

6. Rich Network Management Functions: Intelligent Operations and Maintenance, Improving Efficiency

The Industrial Ethernet Switch ISG integrates multiple network management tools to reduce operational complexity:

Network Management Functions:

Port Mirroring: Real-time monitoring of specific port data streams for troubleshooting.

Web Management: Configures device parameters via a browser without requiring dedicated software.

QoS (Quality of Service): Prioritizes bandwidth for critical services (such as video surveillance).

VLAN Segmentation: Logically isolates different departments or devices to enhance security.

Routing Functions: Supports static routing and dynamic routing protocols (such as OSPF) to optimize data forwarding paths.

Link Aggregation: Combines multiple physical links into a logical link to increase bandwidth and reliability.

Storm Suppression: Prevents broadcast and multicast storms from occupying bandwidth, ensuring network stability.

Application Scenarios:

Large Factories: Isolate production and office networks through VLANs to prevent data leakage.

Data Centers: Utilize link aggregation to increase bandwidth between core switches and servers.

7. Rich Interface Options: Meeting Diverse Scenario Requirements

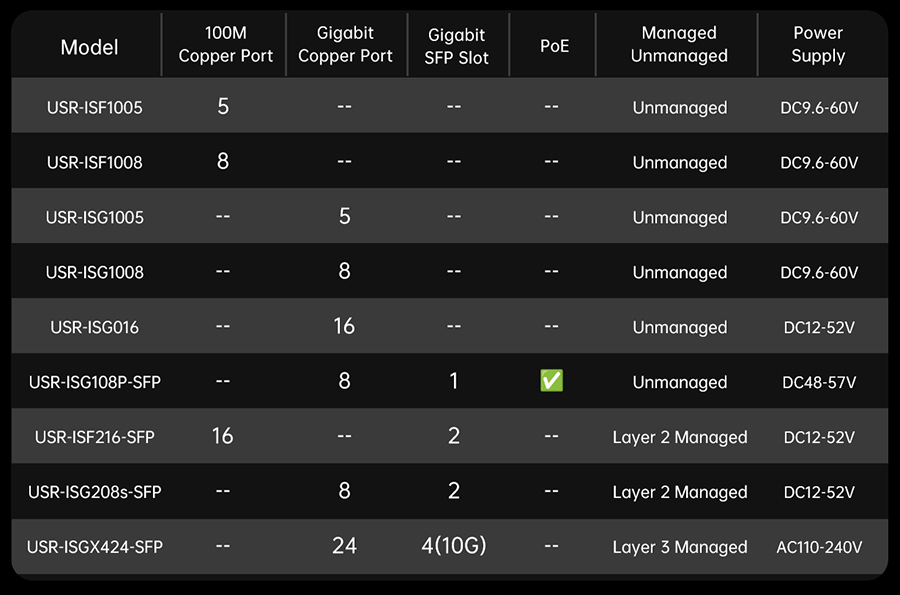

The Industrial Ethernet Switch ISG offers various models with 5, 8, 16, and 24 ports, supporting 100Mbps/1000Mbps speeds and combinations of electrical and optical ports:

7.1 Classification by Port Quantity: Flexibly Adapting to Network Scale

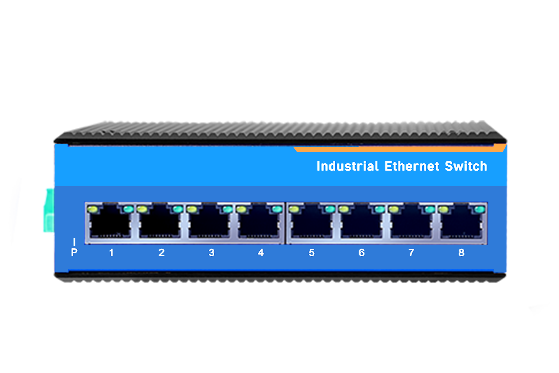

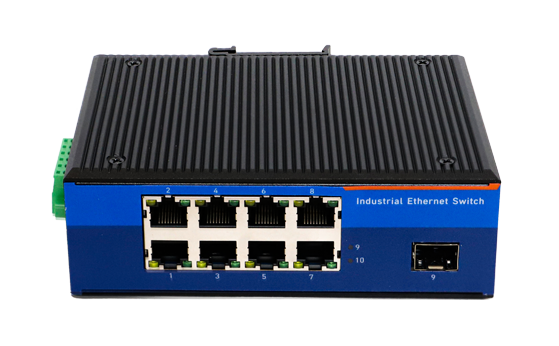

5-Port/8-Port Industrial Switches

Application Scenarios: Small equipment rooms, branch networks, or terminal access layers.

Typical Industries:

Retail Stores: Connect cash register systems, surveillance cameras, and POS machines, requiring compact layouts and low costs.

Workstations: Connect PLCs, sensors, and other few devices, with limited space and simple cabling.

Smart Homes: Network automation equipment in home factories or small laboratories.

Advantages: Compact size, supports DIN rail mounting, saves space; low cost, suitable for budget-sensitive scenarios.

16-Port/24-Port Industrial Switches

Application Scenarios: Core layers of medium to large networks or equipment-dense environments.

Typical Industries:

Factory Headquarters: Connect dozens of devices such as production lines, robots, and AGVs, requiring high-density ports.

Data Centers: Serve as aggregation layer devices, connecting multiple access switches and servers.

Smart Parks: Cover network interconnections across multiple areas such as office buildings, factories, and warehouses.

Advantages: Support more device access, reduce network layers; feature ring redundancy functions to enhance reliability.

7.2 Classification by Speed: Meeting Different Bandwidth Requirements

100Mbps Industrial Switches (10/100Mbps)

Application Scenarios: Traditional industrial settings with low bandwidth requirements.

Typical Industries:

Old Factory Upgrades: Upgrade existing networks, compatible with old equipment (such as non-intelligent sensors).

Environmental Monitoring: Connect weather stations and water quality monitoring devices, with small data volumes and low transmission frequencies.

Security Surveillance: Ordinary camera networks, without requiring high-definition video streams.

Advantages: Low cost, low power consumption, suitable for budget-limited or low-bandwidth scenarios.

1000Mbps Industrial Switches (10/100/1000Mbps)

Application Scenarios: High-bandwidth scenarios requiring high-definition video transmission and real-time processing of large data volumes.

Typical Industries:

Intelligent Manufacturing: Connect industrial cameras and robot vision systems, requiring high-speed data transmission.

Intelligent Transportation: Traffic signal control and vehicle identification systems, requiring low-latency responses.

Energy Monitoring: Power system data acquisition, requiring real-time transmission of large amounts of sensor data.

Advantages: Support gigabit speeds, avoid bandwidth bottlenecks; some models support PoE++ (up to 90W), capable of powering high-definition cameras.

7.3 Classification by Interface Type: Differentiated Applications of Electrical and Optical Port Industrial Switches

Electrical Ports (RJ45)

Transmission Distance: Up to 100 meters (Category 5e/6 network cables).

Application Scenarios:

Short-Distance Connections: Networking equipment within workshops (such as between PLCs and HMIs).

Low-Cost Deployments: Scenarios with limited budgets and no need for long-distance transmission.

PoE Power Supply: Power IP cameras and wireless APs through network cables, simplifying cabling.

Typical Models: USR-ISG1005 (5-port 100Mbps electrical ports), USR-ISG2008 (8-port gigabit electrical ports + PoE).

Optical Ports (SFP)

Transmission Distance: 2 kilometers to 120 kilometers (single-mode/multimode optical fibers).

Application Scenarios:

Cross-Factory/Building Connections: Network interconnections between different workshops within a factory or between headquarters and branches.

Outdoor Deployments: Equipment networking in remote areas such as wind farms and photovoltaic power stations.

Electromagnetic Interference Resistance: Strong electromagnetic environments such as power substations and rail transit.

Typical Models: USR-ISG4016 (16-port gigabit electrical ports + 4-port SFP optical ports), USR-ISG8024 (24-port gigabit electrical ports + 8-port SFP optical ports).

7.4 Industry Application Cases and Selection Recommendations

Manufacturing Industry

Requirements: Connect production equipment, robots, and AGVs, requiring high-density ports and low latency.

Selection: 24-port gigabit electrical port switch (such as USR-ISG8024), supporting ring redundancy.

Advantages: Avoid single points of failure, ensuring 7×24 operation of production lines.

Energy Industry

Requirements: Outdoor equipment networking in wind farms and photovoltaic power stations, requiring lightning protection and long-distance transmission.

Selection: 8-port gigabit electrical port + 4-port SFP optical port switch (such as USR-ISG4008), supporting 6000V lightning protection.

Advantages: Withstand harsh weather conditions, enabling cross-regional data transmission via optical fibers.

Intelligent Transportation

Requirements: Traffic signal control and vehicle identification systems, requiring real-time performance and high reliability.

Selection: 16-port gigabit electrical port switch (such as USR-ISG4016), supporting fast ring redundancy (20ms switching).

Advantages: Prevent traffic paralysis, improving urban traffic efficiency.

Environmental Monitoring

Requirements: Connect weather stations and water quality monitoring devices, requiring low costs and low power consumption.

Selection: 5-port 100Mbps electrical port switch (such as USR-ISG1005), supporting wide temperature operation (-40℃ to 75℃).

Advantages: Adapt to extreme outdoor temperatures, reducing deployment costs.

8. Layer 2 and Layer 3 Switches: Selecting Based on Needs to Optimize Network Architecture

The Industrial Switch ISG is available in Layer 2 and Layer 3 models, adapting to different network scales and complexities:

Layer 2 Switches:

Functions: Forward data based on MAC addresses, supporting basic functions such as VLAN and QoS.

Applicable Scenarios: Small networks or terminal access layers (such as workshop equipment networking).

Layer 3 Switches:

Functions: Support IP routing, enabling cross-subnet communication and policy routing.

Applicable Scenarios: Core layers of large networks or distributed architectures (such as interconnections between data centers across factory sites).

Selection Recommendations:

Simple Networks: Choose Layer 2 switches to reduce costs.

Complex Networks: Choose Layer 3 switches to enhance scalability and management efficiency.

Industrial Switch USR-ISG—The "All-Round Warrior" of Industrial Networks

The PUSR Industrial Switch USR-ISG series of industrial Ethernet switches provides reliable network infrastructure for industries such as energy, transportation, and manufacturing through military-grade hardware design, high protection performance, and intelligent management. Its aluminum alloy enclosure, 6000V lightning protection, ring redundancy, and other technologies directly address pain points in industrial scenarios; while its rich interface options and Layer 2/Layer 3 models meet diverse requirements ranging from simple to complex. In the era of Industry 4.0, the Industrial Switch USR-ISG is not just a "bridge" for data transmission but also an "invisible guardian" ensuring production safety and efficiency.