In smart manufacturing workshops, as robotic arms complete their 100,000th precise weld, edge computing gateways make 12 critical decisions within 0.1 seconds: Is vibration frequency abnormal? Does current fluctuation exceed limits? Does the weld quality captured by vision systems meet standards? This silver box hidden in control cabinets leverages its superpower of processing 500 industrial protocol data points per second to reshape the nerve endings of the Industrial IoT.

In traditional industrial IoT architectures, gateways acted like "courier hubs": simply packaging raw device data for 4G/5G cloud delivery. Yet in industrial scenarios where 10 milliseconds can determine equipment failure, this "mail-then-process" model falls short.

Modern edge gateways have evolved into "smart actuaries":

This evolution compresses processing cycles from seconds to milliseconds, akin to equipping industrial robots with "reflexive nervous systems."

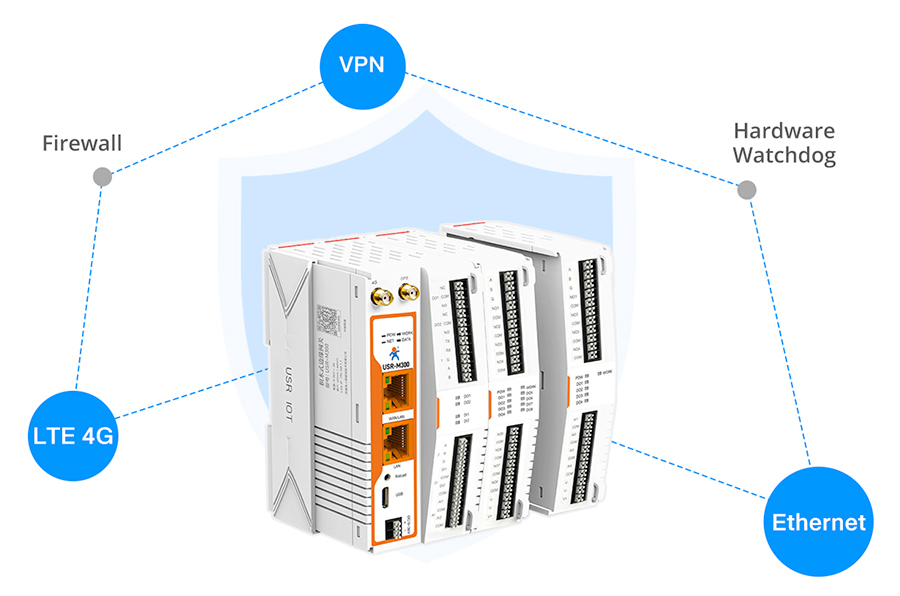

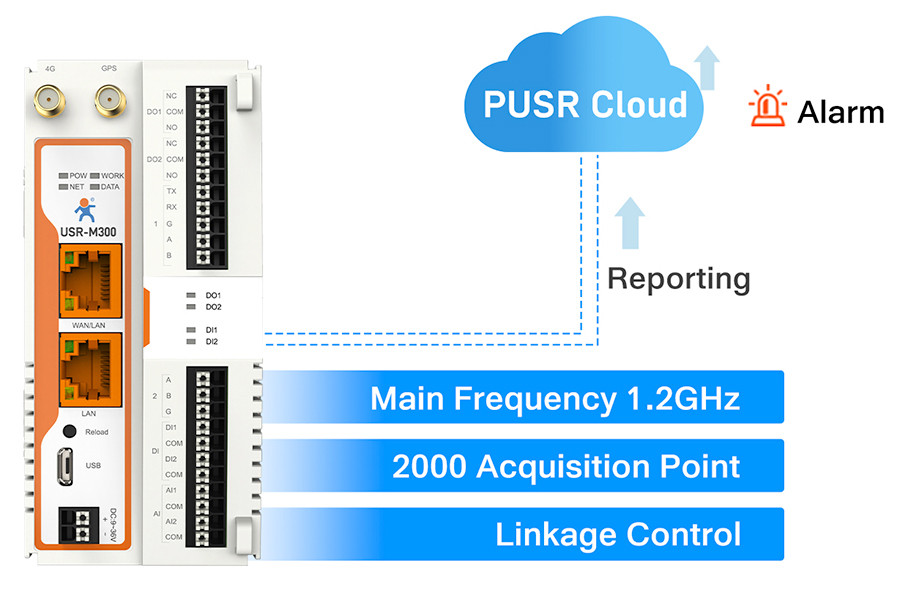

Inside industrial-grade gateways' metal casings lie three layers of technical secrets:

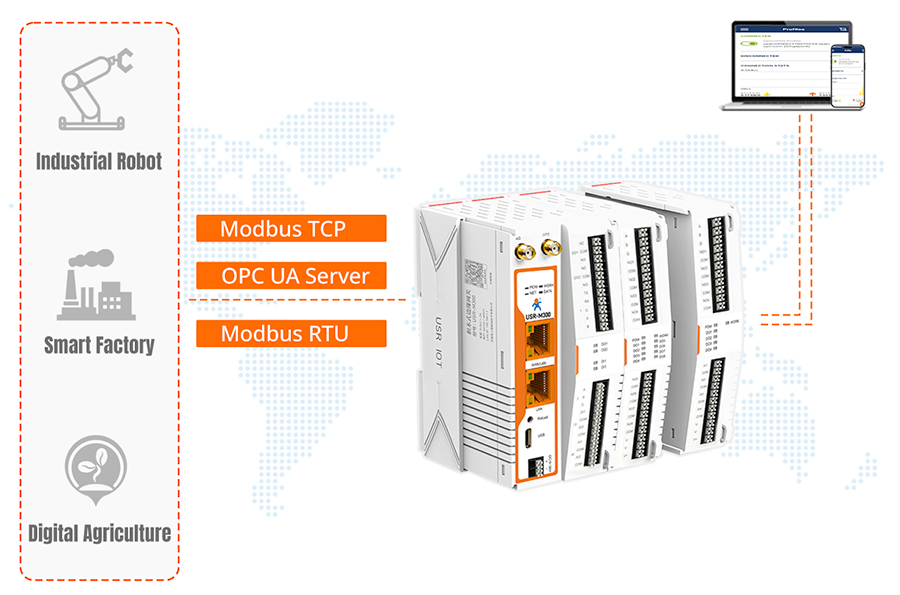

Seamlessly converts 20+ industrial protocols like Modbus RTU and OPC UA, acting as multilingual translators enabling dialogue between 1980s machinery and digital twins. A automotive plant reduced data interoperability costs by 40% using protocol conversion modules to integrate 12 suppliers' heterogeneous equipment.

Employs lightweight rule engines with Lua script customization. On glass production lines, gateways automatically adjust process parameters 8x faster than traditional SCADA systems when infrared thermometer fluctuations exceed ±3℃.

Hosts lightweight AI models for local anomaly detection and predictive maintenance. A wind farm's edge gateway pre-empted gearbox failures 2 weeks in advance through vibration analysis, preventing million-dollar downtime losses.

In steel rolling scenarios, shape defect detection data no longer travels 200km to the cloud. Local processing boosts closed-loop control response speed by 10x, reducing defect rates by 35%.

Biopharmaceutical plants upload only desensitized statistical values after local data cleaning, satisfying compliance while protecting trade secrets—reducing data leakage risks by 90%.

In underground mining operations, edge gateways create "autonomous micro-units" maintaining local control logic during 5G outages, ensuring production continuity.

As edge computing converges with digital twins and AR maintenance, gateways are becoming Industrial Metaverse "nerve nodes." A leading construction machinery enterprise's smart gateways now handle equipment monitoring, AR remote assistance, and process optimization simultaneously—like dedicated "smart butlers" for every machine.

Looking back from the crest of Industry 4.0, edge gateway evolution represents a "data gravity" shift: from centralized cloud processing to emergent edge intelligence. This transformation not only redefines industrial data architectures but also spawns new commercial value networks. For those riding the Industrial IoT wave, understanding gateway "alchemy" means holding the key to unlocking the industrial intelligence era.