In the architecture of the Industrial Internet of Things (IIoT), the connectivity layer serves as the "nerve center" for collaboration between devices and the cloud, as well as between edge and central systems. As core devices at the connectivity layer, 4G industrial routers and 4G industrial modems both undertake data transmission tasks but exhibit significant differences in technical architecture, functional positioning, and application scenarios.

According to IDC forecasts, the number of connected devices in the global IIoT will exceed 50 billion by 2025, with over 60% of connectivity demands relying on dedicated devices that offer high reliability, low latency, and robust security. Leveraging capabilities such as protocol conversion, edge computing, and security encryption, 4G industrial routers have become the preferred choice for scenarios like smart factories and intelligent energy systems. Meanwhile, 4G industrial modems, with their low cost, high flexibility, and transparent transmission features, have carved out a niche in areas such as environmental monitoring and logistics tracking.

This article provides an in-depth analysis of the core differences between 4G industrial routers and 4G industrial modems from three dimensions—technical principles, functional comparisons, and scenario adaptability—while incorporating real-world product characteristics and enterprise case studies to offer decision-making guidance for equipment selection.

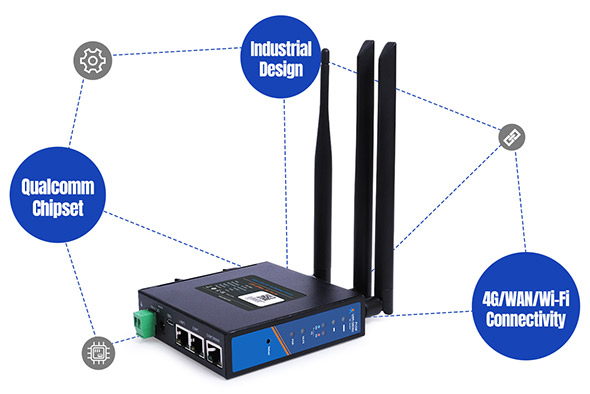

The core function of a 4G industrial router is protocol conversion and network management, with its technical architecture comprising the following key modules:

● Protocol Stack Support:

Supports industrial protocols such as Modbus TCP/RTU, OPC UA, Profinet, and MQTT, as well as internet protocols like TCP/IP, HTTP, and CoAP, enabling interconnection of heterogeneous devices.

● Network Management:

Integrates features such as VPN (IPsec/L2TP), APN/VPDN private networks, and dual-SIM redundancy to ensure secure and reliable data transmission.

● Edge Computing:

Incorporates lightweight AI models and rule engines for data preprocessing and real-time decision-making (e.g., equipment failure prediction, production parameter optimization).

● Hardware Design:

Utilizes industrial-grade chips (e.g., ARM Cortex-A series), wide-temperature operation (-40°C to 85°C), and dustproof/shockproof enclosures to withstand harsh industrial environments.

Case Study: In a smart transformation project at a steel plant, the USR-G816 5G/4G industrial router unified Modbus RTU data from 300 PLCs into MQTT format for cloud upload, leveraging its multi-protocol support. Simultaneously, its edge computing module deployed a vibration analysis model for predictive maintenance of rolling mill bearings, achieving a 95% accuracy rate in failure prediction. The router's 5G low-latency feature (<10ms) ensured real-time remote control, mitigating operational delay risks associated with traditional 4G networks.

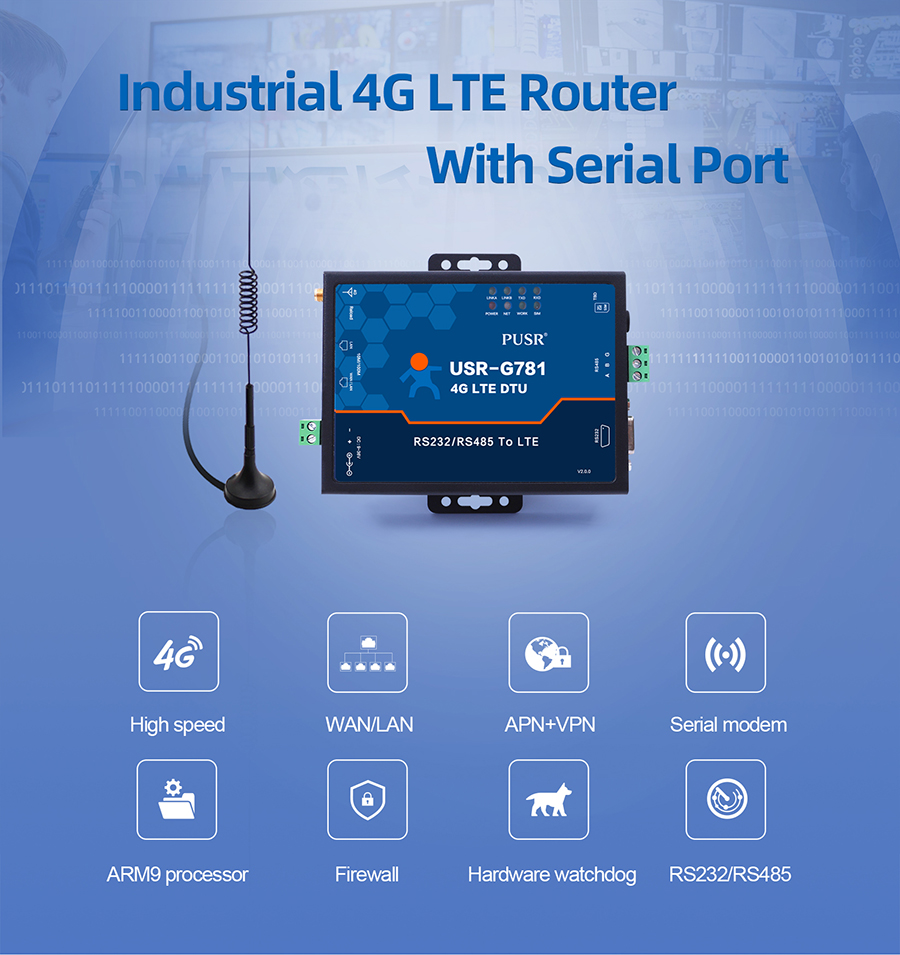

The core function of a 4G industrial modem is data transparent transmission, with its technical architecture focusing on the following characteristics:

● Simplified Interfaces:

Typically provides only serial (RS232/RS485) or Ethernet interfaces for connecting terminal devices like sensors and meters.

● Protocol Adaptation:

Supports TCP/UDP/HTTP protocols, with some high-end models offering lightweight protocols like MQTT and CoAP, but weaker protocol conversion capabilities compared to routers.

● Low-Power Design:

Employs low-power chips (e.g., STM32 series) with standby power consumption <1W, suitable for battery-powered scenarios (e.g., environmental monitoring terminals).

● Rapid Deployment:

Configures parameters via AT commands or configuration tools without complex programming, ideal for large-scale distributed deployments.

Case Study: In a charging station monitoring project, the USR-G786 4G industrial modem connected electric meters via an RS485 interface, transparently transmitting charging data and voltage readings to a cloud platform for remote billing and fault diagnosis. Its "plug-and-play" feature reduced deployment time to just one day per site, while cutting equipment costs by 60% compared to routers, making it a cost-effective choice for distributed scenarios.

| Functional Dimension | 4G Industrial Router | 4G Industrial Modem |

| Protocol Support | Supports 20+ industrial/internet protocols | Typically supports 3-5 basic protocols |

| Network Management | VPN, dual-SIM redundancy, QoS bandwidth optimization | Basic network connectivity, no advanced management functions |

| Edge Computing | Supports AI model inference and rule engines | No computing capabilities, only transparent data transmission |

| Security Protection | Firewall, national cryptographic encryption, intrusion detection | Basic AES encryption, no active defense capabilities |

| Interface Expansibility | Supports WAN/LAN, Wi-Fi, and 4G/5G multi-network integration | Limited to serial or basic Ethernet interfaces |

| Deployment Complexity | Requires configuration of IP addresses, subnet masks, gateways, etc. | Only requires server IP and port settings |

● Protocol Conversion Capability: Routers enable multi-level protocol conversion (e.g., "Modbus RTU → MQTT → OPC UA"), while modems typically support only single-level conversion (e.g., "serial → TCP").

● Security Level: Routers meet Class III requirements of China's Information Security Technology - Classification Protection of Information Systems (GB/T 22239-2019) through VPN tunnels and SM4 encryption, whereas modems comply only with basic Class I standards.

● Cost Structure: Routers generally cost 2-3 times more than modems but offer lower long-term operational costs (e.g., lower failure rates, better scalability).

Pain Points: Fragmented protocols across production line equipment (e.g., PLCs using Modbus, robots using EtherCAT) and stringent real-time control requirements (latency <10ms).

Solutions: Routers enable device interconnection through protocol conversion, with edge computing modules executing real-time control logic (e.g., AGV path planning). 5G networks ensure low-latency transmission.

Product Recommendations: For factories with 5G private networks, the USR-G816 5G industrial router provides end-to-end latency <1ms and supports 20 concurrent device connections, meeting high-density production line demands. For budget-constrained 4G-based projects, the USR-G806W 4G industrial router offers similar functionality at a lower cost.

Pain Points: Widely distributed wind farms and photovoltaic power stations require remote monitoring of equipment status (e.g., inverter temperature, wind turbine vibration).

Solutions: Routers transmit encrypted data via VPN private networks, with edge computing modules performing preliminary analysis (e.g., vibration spectrum analysis). Cloud-based AI models further optimize maintenance strategies.

Case Study: After deploying the USR-G816, a wind farm improved equipment failure prediction accuracy from 70% to 92%, reducing annual maintenance costs by RMB 3 million. Its IP65 protection rating and -40°C to 85°C wide-temperature operation make it suitable for harsh outdoor environments.

Pain Points: Scattered monitoring points (e.g., water quality sensors, weather stations), small data volumes (hourly sampling), and limited budgets.

Solutions: 4G industrial modems connect sensors via serial interfaces and transparently transmit data to the cloud in low-power mode, supporting solar power and LoRaWAN narrowband communication.

Product Recommendations: The USR-G786 4G industrial modem features dual RS485/RS232 interfaces for connecting multiple sensors (e.g., temperature, humidity, PM2.5). Its "zero-configuration" transparent transmission mode reduces single-point deployment time from 2 hours to 10 minutes, making it the top choice for environmental monitoring projects.

Pain Points: Cold chain transportation requires real-time monitoring of temperature and humidity, but vehicle space is limited, necessitating compact devices.

Solutions: 4G industrial modems integrate temperature/humidity sensors and 4G modules, uploading data to the cloud via MQTT protocol while supporting GPS positioning and anomaly alerts.

Product Recommendations: For projects requiring routing capabilities (e.g., onboard device interconnection), the USR-G781 4G industrial modem with routing functionality offers Wi-Fi hotspots and LAN interfaces for local networking of vehicle-mounted devices (e.g., surveillance cameras, electronic displays), while uploading core data to the cloud via 4G.

Router-Modem Integration: Some manufacturers now offer "industrial gateways" that combine the protocol conversion capabilities of routers with the transparent transmission functions of modems, catering to small-to-medium-sized scenarios. For example, the USR-G781 can switch between "routing mode" and "modem mode" via software configuration, adapting to project needs at different stages.

AI Empowerment of the Connectivity Layer: Both routers and modems are beginning to incorporate lightweight AI models for localized anomaly detection (e.g., excessive equipment vibration, network attacks). The USR-G816 already supports edge-based filtering of abnormal data, reducing (invalid) cloud transmissions by 30%.

Cloud Platform Integration: Both routers and modems support seamless integration with platforms like Alibaba Cloud and Huawei Cloud for device management, data analysis, and visualization. USR series devices have obtained Huawei Cloud IoT certification, enabling rapid integration into existing enterprise systems.

Standardization of Industry Protocols: The promotion of new standards such as OPC UA over TSN and 5G LAN will enhance protocol compatibility for routers and modems, reducing integration costs for enterprises.

The difference between 4G industrial routers and 4G industrial modems essentially boils down to a trade-off between "comprehensive solutions for complex scenarios" and "极致 (ultimate) cost-effectiveness for simple scenarios." Enterprises should follow these principles when selecting equipment:

Protocol Complexity:

If devices use diverse protocols (e.g., connecting PLCs, robots, and sensors simultaneously), prioritize routers like the USR-G816.

Real-Time Requirements:

For low-latency control applications (e.g., AGV coordination, remote surgery), routers are the only viable option.

Budget Constraints:

If single-device costs are a critical factor (e.g., environmental monitoring, agricultural irrigation), modems like the USR-G786 offer greater advantages.

Security Level:

For applications involving core data (e.g., power monitoring, financial terminals), routers represent the compliance baseline.

In the vast expanse of the IIoT, routers and modems are not competitors but complementary ecosystem partners. Only by precisely matching equipment to scenario requirements can enterprises unlock the maximum value of the connectivity layer.