In today's era of deep integration between Industry 4.0 and the Internet of Things (IoT), the compatibility issue between traditional serial devices and modern network systems has become a core pain point restricting intelligent upgrades. The 8 Port Serial to Ethernet Converter N580 launched by PUSR serves as a bridge connecting legacy devices to cloud platforms, thanks to its eight independent serial ports, edge computing capabilities, multi-protocol support, and industrial-grade protection design.

1. Core Product Functions: Solving the "Last Mile" Challenge in Industrial Communication

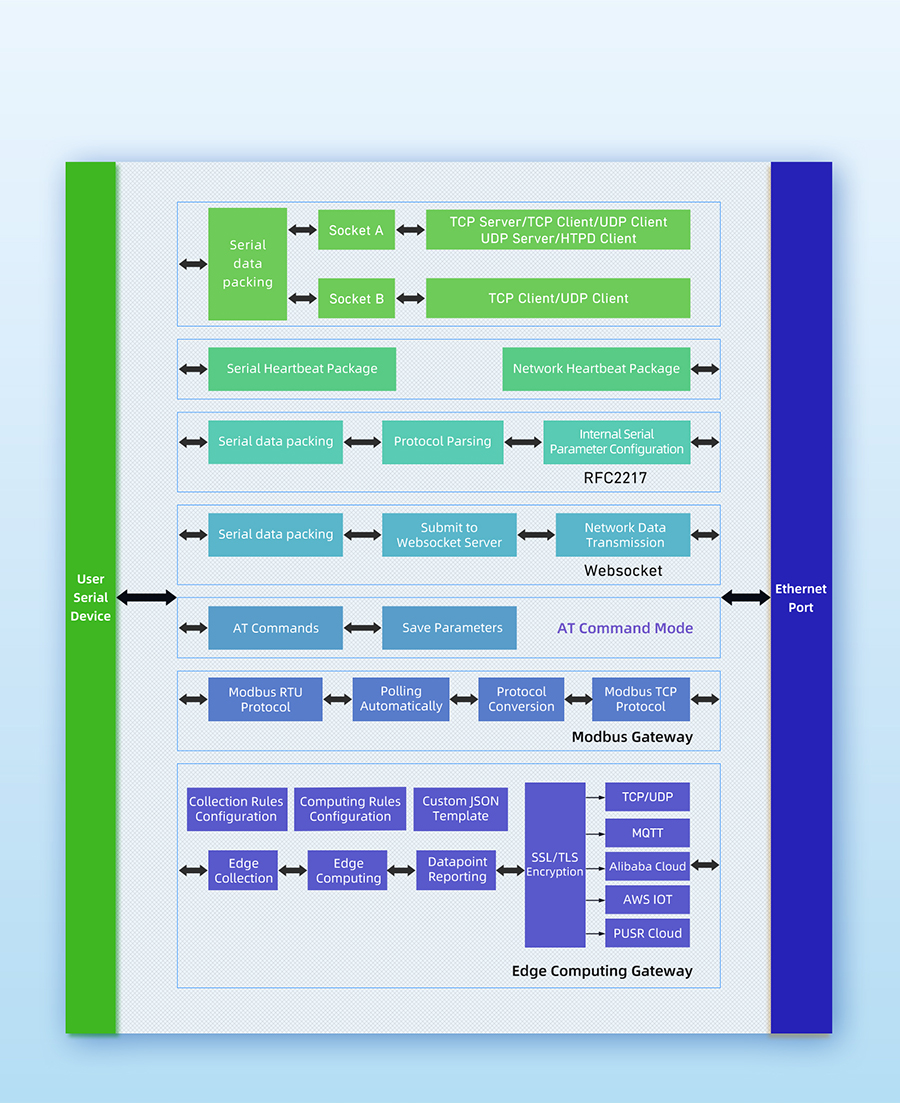

1.1 Multi-Protocol Conversion Hub

The 8 Port Serial to Ethernet Converter N580 supports bidirectional transparent transmission between eight RS485/RS232 serial ports and Ethernet, enabling simultaneous connection to eight industrial devices with different protocols (such as PLCs, sensors, and meters). It encapsulates serial data into IP packets through its built-in TCP/IP protocol stack, achieving seamless integration between devices and cloud platforms. For example, in a smart factory, eight legacy RS485 temperature sensors can be directly connected to the MES system via the 8 Port Serial to Ethernet Converter N580 without the need for hardware replacement.

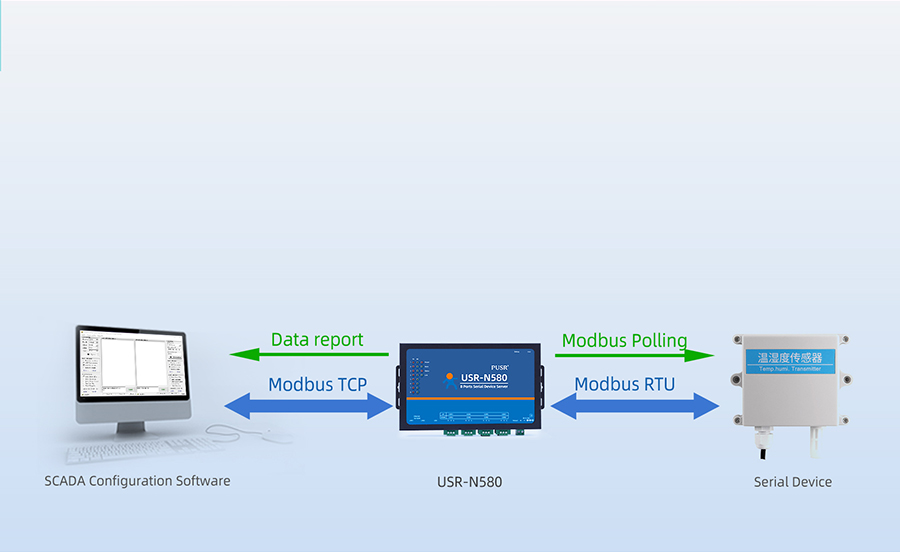

1.2 Breakthrough in Protocol Compatibility

Modbus RTU/TCP Dual Protocol Support: Built-in Modbus gateway functionality automatically converts between Modbus RTU (serial) and Modbus TCP (network) protocols, resolving polling conflicts among multiple hosts. For instance, in an electric power monitoring system, the N580 can simultaneously respond to polling requests from three SCADA master stations, supporting the collection and address mapping of 128 data points.

Deep Integration of MQTT Protocol: Supports standard MQTT protocol connections to mainstream platforms such as Alibaba Cloud and AWS IoT, enabling direct publication of device data to cloud topics and reducing reliance on intermediate servers. Test data shows that MQTT transmission latency is below 50ms at a baud rate of 115200bps, meeting real-time monitoring requirements.

1.3 Edge Computing Empowering Lightweight Decision-Making

The 8 Port Serial to Ethernet Converter N580 is equipped with an Arm Cortex-M7 processor (480MHz clock speed), enabling local data preprocessing capabilities:

Data Aggregation: Real-time summation and average calculation of data from eight sensors, uploading only key indicators to the cloud.

Rule Engine: Configurable threshold alarms (e.g., triggering an alert when temperature exceeds 80°C) to reduce cloud computing pressure.

Automatic JSON Generation: Converts binary serial data into standard JSON format according to preset templates, such as mapping Modbus register values to {"device_id": "N580_01", "temp": 25.5, "status": "normal"}, simplifying cloud parsing processes.

2. Typical Application Scenarios and Device Access Solutions

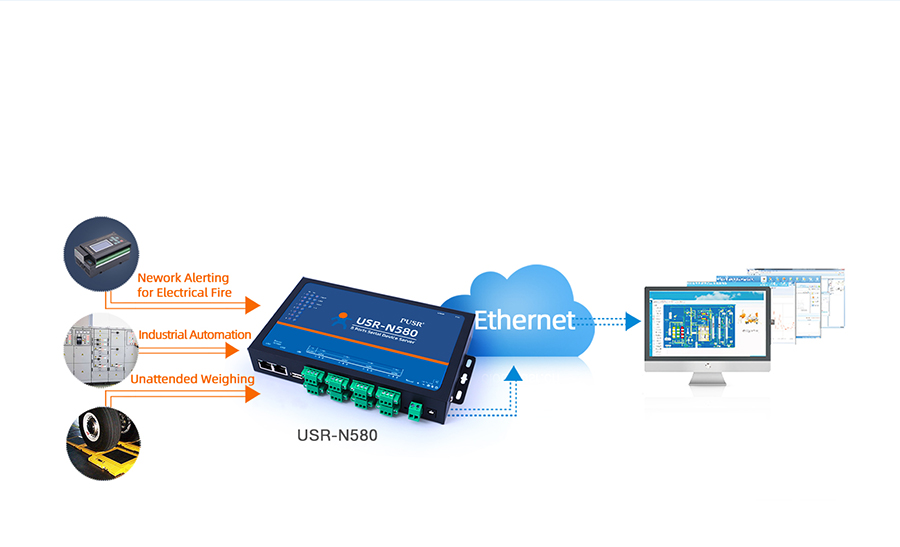

Scenario 1: Industrial Automation Network Monitoring (RS485 Application)

Connected Devices: PLCs, frequency converters, smart meters, temperature and humidity sensors

Case Study: An automobile manufacturing plant uses the 8 Port Serial to Ethernet Converter N580 to connect eight Siemens S7-1200 PLCs, enabling real-time production data collection via the Modbus TCP protocol. The cascading functionality of the N580 (dual Ethernet ports supporting switch mode) expands network coverage, allowing a single device to manage over 50 nodes.

Value Points:

Eliminates protocol silos and unifies data outlets

Reduces cloud load by 30% through edge computing

Industrial-grade protection (EFT/surge/ESD Level 3 protection) adapts to electromagnetic interference environments

Scenario 2: Unattended Weighing System (RS232 Application)

Connected Devices: Weighing instruments, barrier gate controllers, RFID readers, LED displays

Case Study: A logistics park deploys the 8 Port Serial to Ethernet Converter N580 to automate the entire weighing process:

Vehicle RFID cards trigger the N580 to read weighing instrument data

The edge computing module validates data (e.g., weight fluctuation thresholds)

Data is pushed to the cloud management system via MQTT

Controls barrier gate switching and LED display results

Value Points:

Eight serial ports operate independently to avoid device conflicts

JSON format data directly interfaces with ERP systems

SSL/TLS encryption ensures transaction data security

Scenario 3: Electrical Fire Networked Alarm (High Reliability Requirements)

Connected Devices: Electrical fire detectors, smoke sensors, audible and visual alarms

Case Study: A commercial complex uses the N580 to build a fire warning network:

Eight RS485 interfaces connect detectors from different brands (supporting multi-protocol adaptation)

The edge computing module analyzes current/temperature anomalies in real time

MQTT protocol ensures reliable delivery of alarm information at QoS Level 2

Cloud-based (coordination) with fire emergency plans

Value Points:

600W surge protection handles power grid fluctuations

Dual power redundancy design (DC9-48V wide input voltage range)

7×24-hour hardware watchdog ensures system stability

3. In-Depth Analysis of Core Functions

3.1 MQTT Protocol Transmission: A Lightweight IoT Communication Tool

Technical Advantages:

Supports MQTT versions 3.1/3.1.1/5.0

Two-way certificate authentication (TLS 1.2)

Retained Message and Last Will functionalities

Applicable Scenarios:

Remote device management (e.g., monitoring inverter stations in photovoltaic power plants)

Mobile asset tracking (data backhaul from vehicle-mounted sensors)

Narrowband network environments (integration with 4G Cat.1 modules)

User Profiles:

IoT platform operators

Device manufacturers (OEM/ODM)

System integrators (SI)

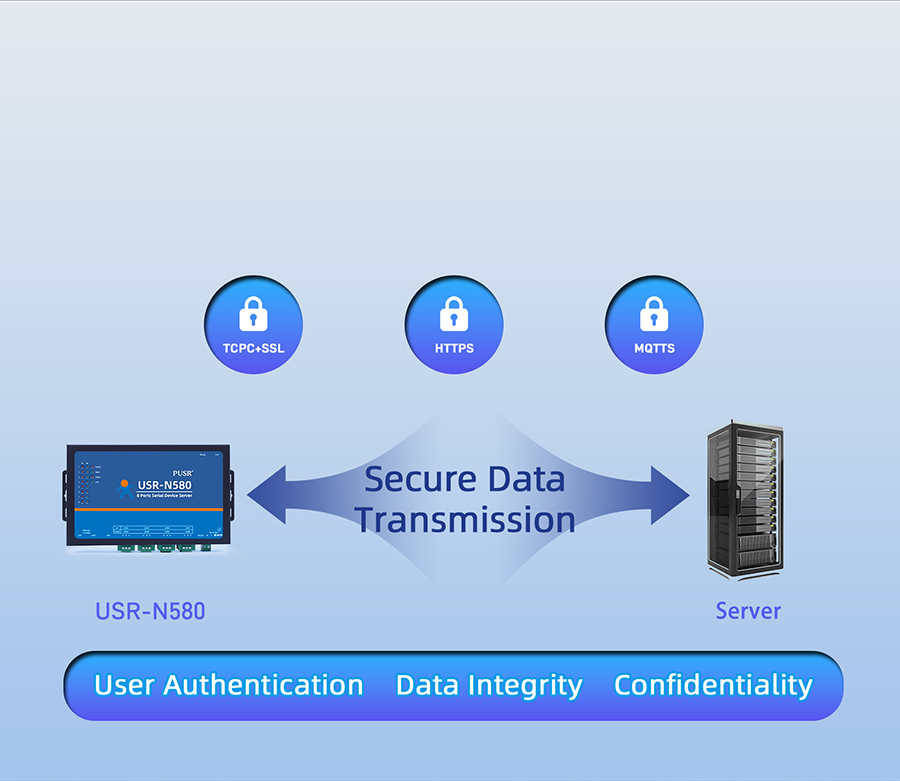

3.2 Data Encryption Transmission: Safeguarding Industrial Control Security

Encryption Schemes:

TCP/UDP mode: SSL/TLS 1.2 encryption

HTTP mode: HTTPS forced redirection

MQTT mode: X.509 certificate two-way authentication

Typical Applications:

Energy management system (EMS) data collection

Smart water SCADA systems

Remote maintenance of medical equipment

Security Certifications:

Complies with IEC 62443-4-2 industrial cybersecurity standards

Meets GDPR data privacy protection requirements

3.3 Modbus Gateway: Solving Multi-Host Communication Challenges

Functional Characteristics:

Supports simultaneous connection of 32 Modbus TCP clients

Configurable automatic polling intervals (10ms-10s)

Data caching mechanism (offline retransmission)

Application Case:

In a steel plant's blast furnace monitoring system, the 8 Port Serial to Ethernet Converter N580 connects eight pressure transmitters, simultaneously responding to requests from DCS and energy management systems via Modbus multi-host functionality to avoid data conflicts.

Test data shows that a single 8 Port Serial to Ethernet Converter N580 can stably support 2,000 register read/write operations per second in a 100Mbps network environment.

4.Technical Specifications and Deployment Recommendations

Key Indicators

Parameter Item | Specification Description |

Processor | Arm Cortex-M7 (480MHz) |

Memory | 1MB RAM + 4MB Flash |

Serial Port Type | 8×RS485 (optional RS232/RS422) |

Baud Rate | 600-921600bps (adaptive) |

Network Interface | 2×10/100Mbps Ethernet (supports cascading) |

Operating Temperature | -40°C~85°C (industrial grade) |

MTBF | >50,000 hours |

Deployment Topology Recommendations

Star Topology: Suitable for centralized device scenarios (e.g., computer room monitoring), with a single 8 Port Serial to Ethernet Converter N580 serving as the central node connecting all devices.

Chain Topology: Extended via dual Ethernet port cascading, suitable for long-distance distributed deployments (e.g., oil pipeline monitoring).

Hybrid Topology: Combines star and chain topologies to build redundant networks (e.g., intelligent traffic signal control systems).

5.Industry Value and Future Evolution

The launch of the

8 Port Serial to Ethernet Converter N580 marks a transition of industrial communication devices from "simple conversion" to "intelligent gateways." Its core value is reflected in:

Cost Optimization: A single device replaces eight traditional serial servers, saving 70% in hardware costs.

Efficiency Improvement: Edge computing reduces cloud data volume, lowering bandwidth consumption by 40%.

Security Enhancement: End-to-end encryption meets Level 3 requirements of the Cybersecurity Classification Protection 2.0 standard.

In the future, the 8 Port Serial to Ethernet Converter N580 will support new technologies such as 5G NR and TSN (Time-Sensitive Networking) through OTA upgrades, continuously empowering the evolution of industrial IoT toward deterministic networks. For enterprises seeking digital transformation, choosing the N580 is not merely selecting a hardware product but making a strategic investment in building future-ready factory communication infrastructure.