The data collection system for the equipment in the automatic production line mainly applies to the data collection in different production sites, which is highly accurate and is able to conduct unified management to the collection equipment. The data is transferred to the database through IOT devices(such as serial to Ethernet converters) and will have a complete management to the working process, procedure parameters, device type, device parameters of the whole production line.

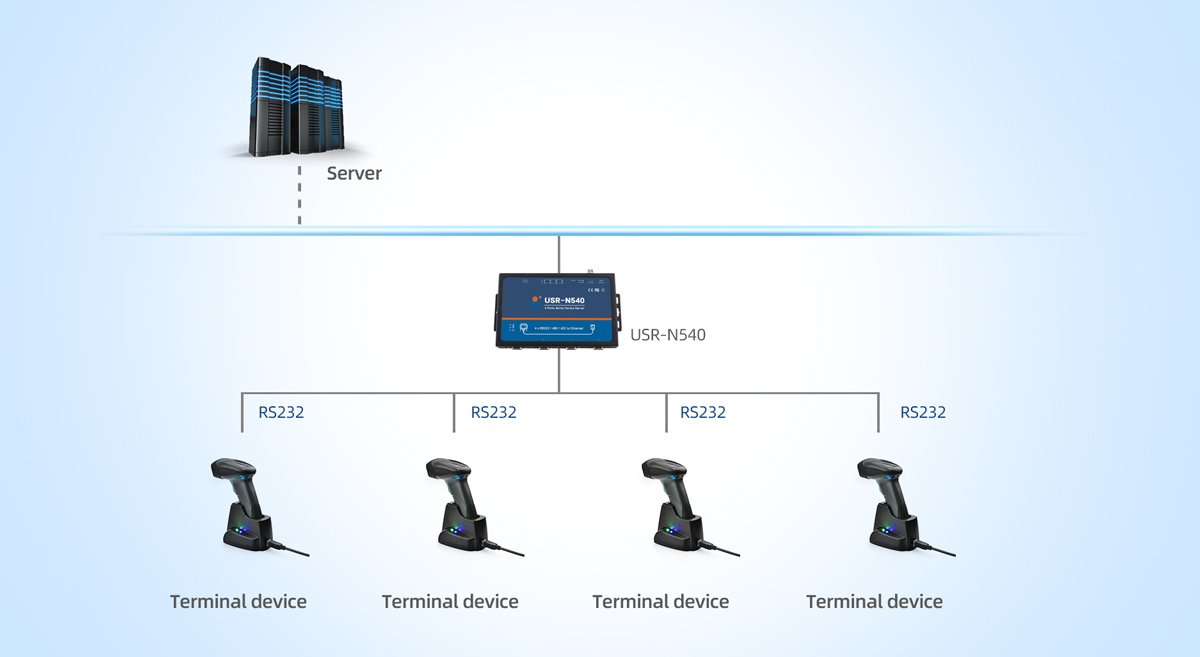

1. Serial to Ethernet converter with four serial ports means the data of the four RS232 equipment can transfer to the sever simultaneously.

2. The serial to Ethernet converters are connected to the equipment in the production line like QR code scanner. The four serial ports work independently without affecting each other.

3. The other end of the serial-to-Ethernet converter is connected to the network through an RJ45 network cable. Serial data is packaged and sent to the IP channel through the internal TCP/IP protocol stack and then is converted to network data.

4. According to the needs of the site conditions, serial to Ethernet converter with different port numbers is chosen and connected to the network directly to collect data.

1. Easy maintenance and strong scalability.

2. Save costs and improve system reliability.

3. Improve production line management efficiency and automation.

4. No need to eliminate the original serial device.

Serial to Ethernet converter USR-N540

USR-N540 is an Industrial Serial to Ethernet Converter to realize bi-directional transparent transmission between RS232/RS485/RS422 and network with function of modbus gateway.

4 serial ports, each one can select RS232/ RS485/RS422

Hardware Watchdog, keep to work stable

Modbus RTU -TCP, Customized webpage, websocket

Serial ports can work simultaneously