PUSR Industrial IoT Gateway USR-M300: An All-Round Hub Reshaping Industrial Intelligence

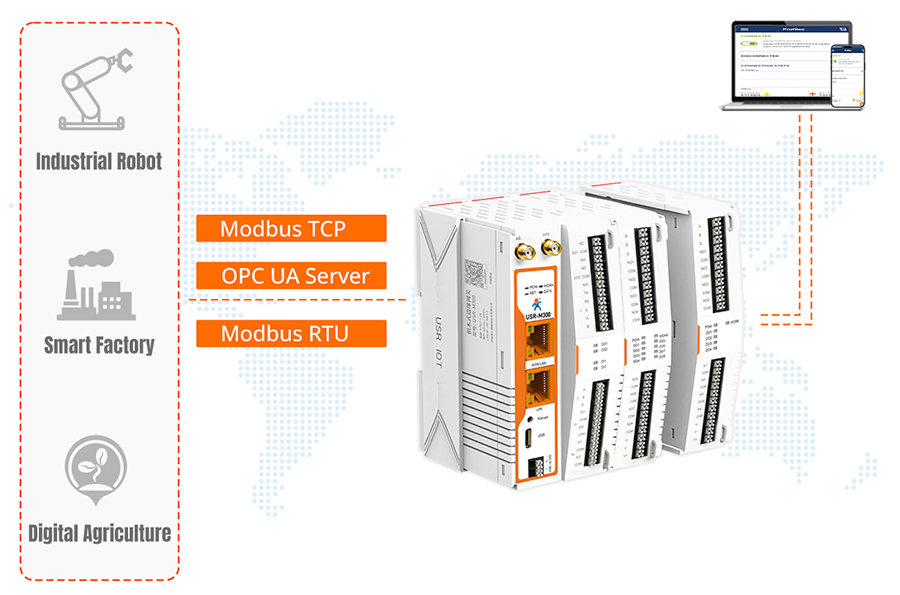

In today's world where the wave of Industry 4.0 is sweeping across the globe, the Industrial Internet of Things (IIoT) has become the core driving force for enterprise digital transformation. As a bridge connecting the physical world and the digital world, an industrial IoT gateway not only needs to undertake basic functions such as data collection and protocol conversion but also requires advanced capabilities like edge computing, flexible expansion, and secure communication. PUSR's USR-M300 industrial IoT gateway, with its "building block" design concept, a powerful edge computing core, and full-scenario protocol support, redefines the standards for industrial gateways and has become the preferred solution in fields such as smart factories, smart agriculture, and energy management.

1. What is an IoT Gateway? The Core Value of Industrial IoT Gateways

An industrial IoT gateway serves as a "digital translator" connecting industrial equipment to cloud platforms. Its core functions include:

Protocol Conversion: Transforming private protocols (such as Modbus RTU/TCP, OPC UA, and Profinet) of different industrial equipment (such as PLCs, sensors, and controllers) into standard protocols (such as MQTT and HTTP) to enable seamless communication between equipment and the cloud.

Edge Computing: Completing data preprocessing, logical judgment, and real-time control at the device end, reducing reliance on the cloud, and lowering latency and bandwidth costs.

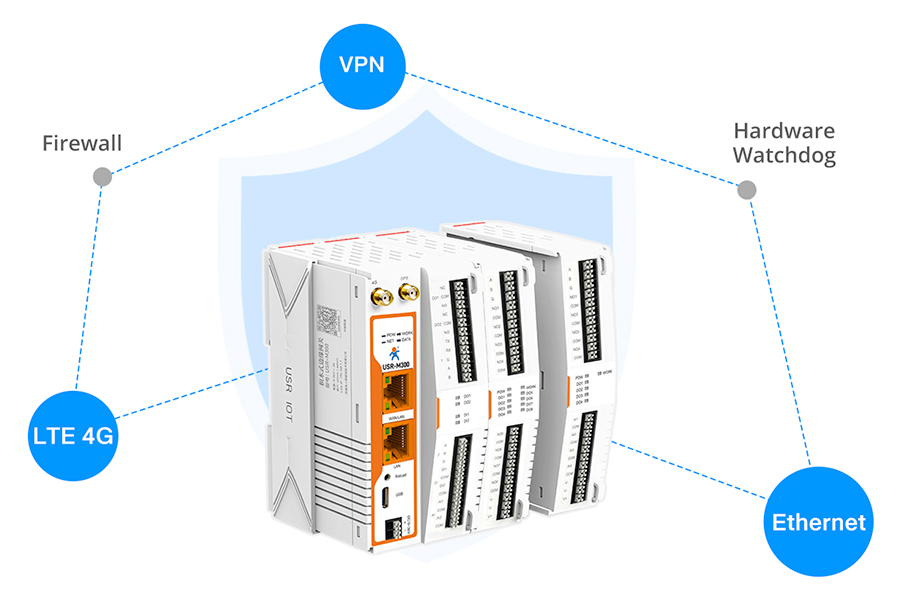

Security Protection: Ensuring the security of data during transmission through VPNs, firewalls, and encrypted transmission technologies.

Device Management: Supporting remote configuration, firmware upgrades, and fault diagnosis to reduce operation and maintenance costs.

As a high-performance industrial IoT gateway, the USR-M300 not only possesses the above basic functions but also provides enterprises with a one-stop industrial intelligence solution through its modular design, graphical programming, and ultra-strong edge computing capabilities.

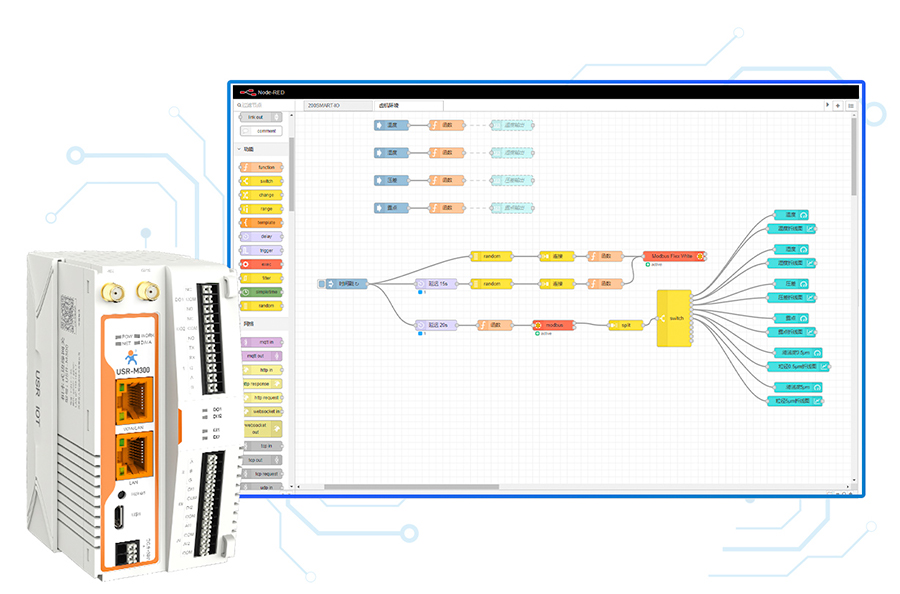

2. Node-RED: A Graphical Programming Tool for the IoT Gateway M300

2.1 What is Node-RED?

Node-RED is an open-source visual programming tool based on Node.js. It allows for the rapid construction of IoT applications without writing code by dragging and dropping nodes and connecting lines (flows). Its core advantages include:

Low-Code Development: Users can access the built-in editor via a browser to intuitively design data flow logic.

Cross-Platform Compatibility: Supports operation in various environments such as Raspberry Pi, industrial PCs, and cloud servers.

Rich Node Library: Provides hundreds of pre-built nodes covering common functions such as HTTP, MQTT, databases, and email.

Process Sharing: Supports the export/import of process files in JSON format, facilitating team collaboration and knowledge reuse.

2.2 Analysis of the Node-RED Function of the IoT Gateway M300

The IoT Gateway M300 deeply integrates Node-RED, allowing users to directly develop edge logic via the web interface:

Data Collection and Processing: Read PLC data through Modbus nodes or collect sensor signals through serial port nodes, and use function nodes for data cleaning and conversion.

Real-Time Control: Achieve conditional device (e.g., automatically starting a fan when the temperature exceeds a limit) by combining switch nodes and logical judgment nodes.

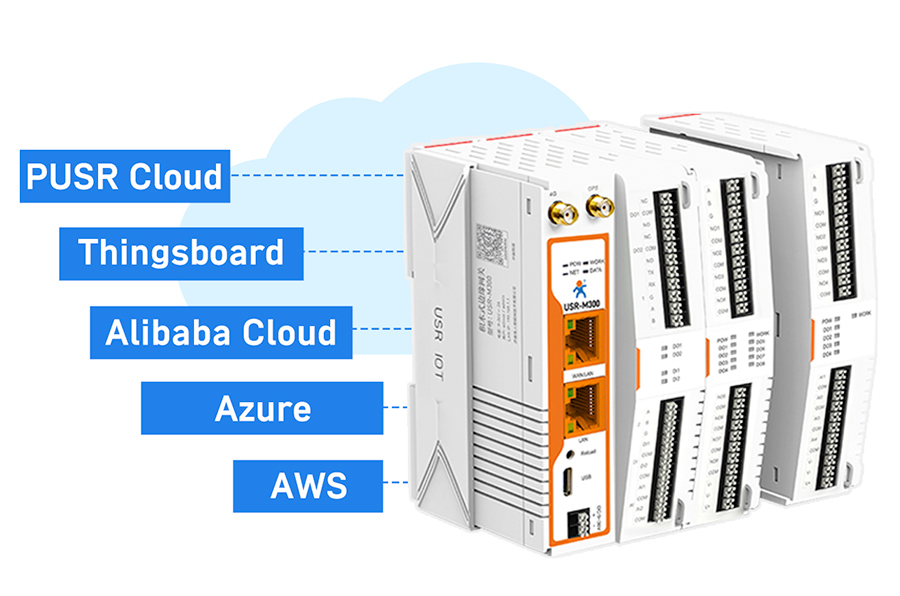

Cloud Communication: Report data to platforms such as Alibaba Cloud and AWS through MQTT nodes or call third-party APIs through HTTP nodes.

Custom Expansion: Support the installation of third-party node libraries to meet personalized needs (such as GPS positioning and image recognition).

Application Case:

In a smart farming scenario, users can design the following process using Node-RED:

Read temperature and humidity sensor data through Modbus nodes;

Use function nodes to determine whether the data exceeds the threshold;

If it does, control the ventilation equipment to start through GPIO nodes;

At the same time, report the data to the cloud through MQTT nodes to generate visual reports.

The entire process can be completed without writing a single line of code, simply by dragging and dropping nodes.

3. Ultra-Strong Edge Computing: The Core Value Brought by the Industrial IoT Gateway M300 to Enterprises

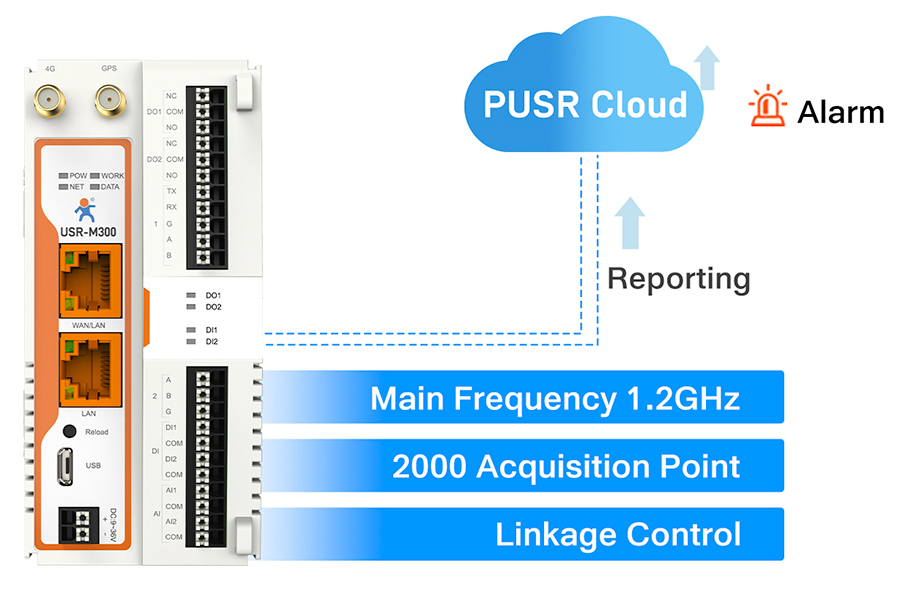

The Industrial IoT Gateway M300 is equipped with a 1.2GHz dual-core processor and supports real-time processing of up to 2000 data points. Its edge computing capabilities can bring the following advantages to enterprises:

3.1 Reducing Cloud Load and Saving Bandwidth Costs

Traditional solutions require uploading all raw data to the cloud for processing, while the Industrial IoT Gateway M300 can complete data aggregation, filtering, and preliminary analysis locally, only reporting key results. For example, in a production line monitoring scenario, the gateway can calculate the average value of 1000 temperature data points collected per second and only upload abnormal values, reducing data transmission volume by 90%.

3.2 Achieving Real-Time Response and Improving System Reliability

Edge computing enables device control without relying on cloud instructions, reducing response latency from seconds to milliseconds. In a smart factory, the Industrial IoT Gateway M300 can monitor motor vibration data in real time, judge equipment failure risks through local algorithms, and immediately trigger shutdown protection to avoid accident escalation.

3.3 Supporting Offline Operation and Ensuring Business Continuity

When the network is interrupted, the Industrial IoT Gateway M300 can continue to execute preset logic (such as data caching and local control) and automatically synchronize data after the network is restored. This function is particularly important in environments with unstable networks such as remote areas or underground mines.

4. Expandable IO Modules: The "Building Block" Design Philosophy of the Industrial IoT Gateway M300

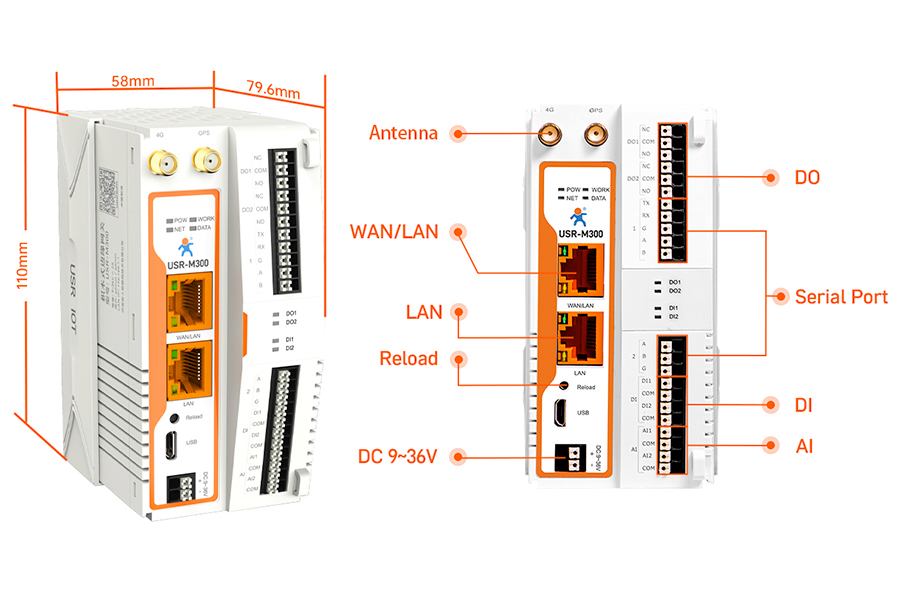

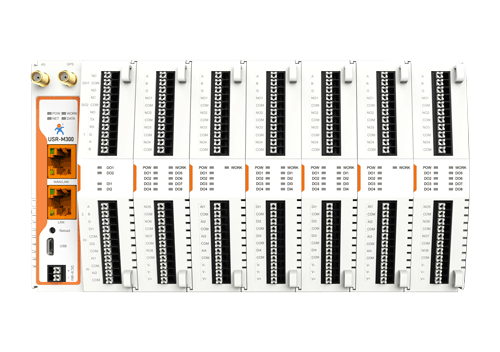

The Industrial IoT Gateway M300 adopts a modular design. The main unit comes standard with 2 digital inputs (DI), 2 digital outputs (DO), and 2 analog inputs (AI), and supports the addition of IO interfaces through expansion units:

Expansion Capability: Up to 6 expansion units can be connected, with each expansion unit providing 8 IO interfaces and supporting flexible combinations of DI, DO, AI, and analog outputs (AO).

Intelligent Identification: The gateway can automatically identify the type of the expansion unit and compare it with the pre-configuration. If the types do not match, it will alarm through indicator lights.

Application Scenarios:

Smart Factory: Connect more sensors (such as pressure, flow, and displacement sensors) and actuators (such as solenoid valves and servo motors) to achieve comprehensive monitoring and control of the production line.

Smart Agriculture: Expand sensor interfaces for soil moisture and light intensity to build a precision irrigation system.

Energy Management: Connect metering equipment such as electricity meters and water meters to achieve centralized collection and analysis of energy consumption data.

5. Can the IoT Gateway M300 Be Used as an IoT Router?

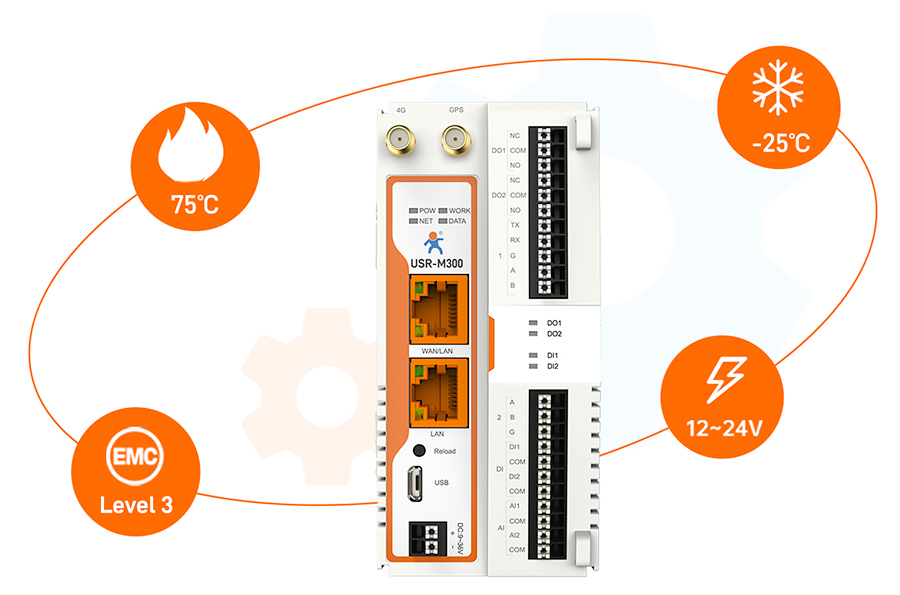

The IoT Gateway M300 is not only a gateway but also a high-performance industrial router. Its network functions include:

5.1 Multi-Network Integration to Ensure Communication Continuity

Dual-Network Online Simultaneously: Supports the simultaneous operation of Ethernet (WAN/LAN) and 4G cellular networks, automatically switching to the available network.

Link Detection: Can customize the target address and cycle for detection, monitor the network status in real time, and automatically switch to the backup network within 30 seconds if the main network fails.

VPN Support: Provides various VPN protocols such as PPTP, L2TP, and OpenVPN to ensure the security of remote access.

5.2 Typical Application Scenarios

Mobile Vehicle Monitoring: Deploy the IoT Gateway M300 in logistics vehicles to upload GPS positioning and onboard equipment data in real time through 4G networks, maintaining communication even when the vehicles enter areas without WiFi.

Remote Equipment Management: In scenarios such as wind farms and oil fields, use 4G networks to achieve remote monitoring and maintenance of equipment, reducing on-site inspection costs.

6. Modbus Gateway Function: The Protocol Conversion Expert of the IoT Gateway M300

Modbus is one of the most commonly used communication protocols in the industrial field. The Modbus Gateway function of the IoT Gateway M300 can solve the following problems:

6.1 Protocol Conversion to Break Down Equipment Barriers

Modbus RTU/TCP Interconversion: Convert the RTU protocol of serial port equipment (such as old-fashioned meters) into the TCP protocol to connect to Ethernet.

Modbus to JSON/MQTT: Encapsulate Modbus data in JSON format and report it to the cloud through the MQTT protocol, facilitating the integration of modern IoT platforms.

6.2 Typical Application Scenarios

Old Equipment Renovation: In a smart factory, the IoT Gateway M300 can connect dozens of PLCs using the Modbus RTU protocol without replacing the equipment to achieve data uploading to the cloud.

Multi-Protocol Equipment Integration: In a building automation system, connect equipment using different protocols such as Modbus, BACnet, and OPC UA and manage them uniformly through the IoT Gateway M300.

7. The IoT Gateway M300 as an "Industrial Protocol Gateway"

In addition to Modbus, the IoT Gateway M300 also supports mainstream industrial protocols such as OPC UA, Profinet, and EtherCAT. Its value is reflected in:

7.1 Cross-Brand Equipment Interconnection

In complex scenarios such as automobile manufacturing and semiconductor production, equipment from different manufacturers may use different protocols. The IoT Gateway M300 can serve as a "protocol translator" to achieve interconnection between Siemens PLCs, Mitsubishi motors, Omron sensors, and other equipment.

7.2 Typical Application Scenarios

Automated Production Line: Connect equipment such as robots, AGV trolleys, and visual inspection systems to build a unified data collection and control platform.

Energy Management System: Integrate metering equipment such as electricity meters, gas meters, and water meters to achieve real-time monitoring and optimization of energy consumption data.

8. Server-Level Functions of the Industrial Gateway Server M300

The Industrial Gateway Server M300 is not only a gateway but can also be regarded as a mini industrial server. Its server-level functions include:

Local Data Storage: Built-in with large-capacity storage space, it can cache tens of thousands of historical data records and support offline data resumption.

Local Web Service: Through the built-in web server, users can directly configure gateway parameters, view equipment status, and download data in a browser.

Multi-User Management: Supports hierarchical permission control, allowing users with different roles to access different functional modules.

PUSR's M300 industrial IoT gateway, with its "building block" design, ultra-strong edge computing, full-protocol support, and graphical programming, provides enterprises with a complete solution from device connection and data collection to intelligent control. Whether it is flexible production in smart factories, precision irrigation in smart agriculture, or energy-saving optimization in energy management, the IoT Gateway M300 can, with its powerful functions and flexible expansibility, help enterprises achieve digital transformation and seize the commanding heights of Industry 4.0. Choosing the IoT Gateway M300 is choosing a smarter, more efficient, and more reliable industrial future.