1. What is RS485 to Ethernet

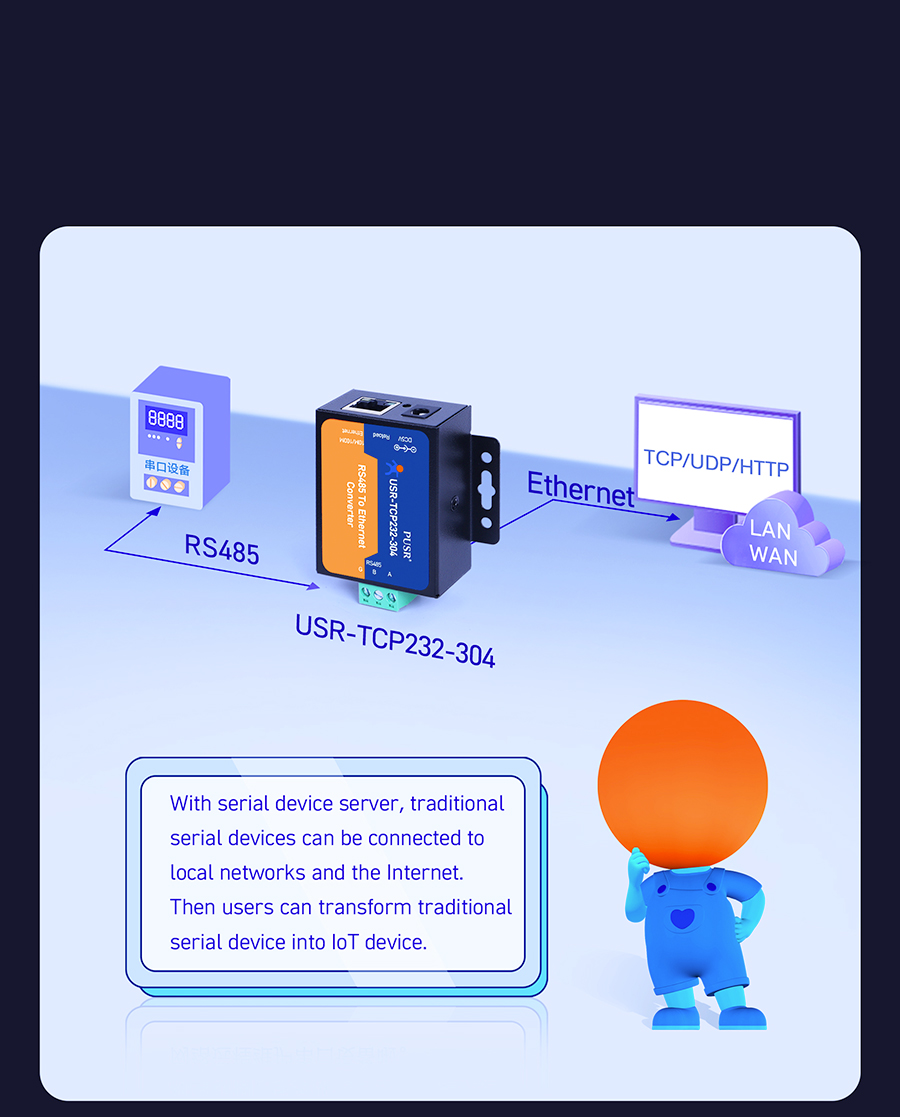

In the context of the rapid development of industrial automation and the Internet of Things (IoT), interconnection and intercommunication among devices have become a core requirement.

However, traditional industrial equipment predominantly adopts the RS485 serial communication protocol, while modern network systems rely on Ethernet (TCP/IP) for efficient data transmission. This protocol difference, akin to the barrier between "dialects" and "Mandarin," prevents direct communication between devices.

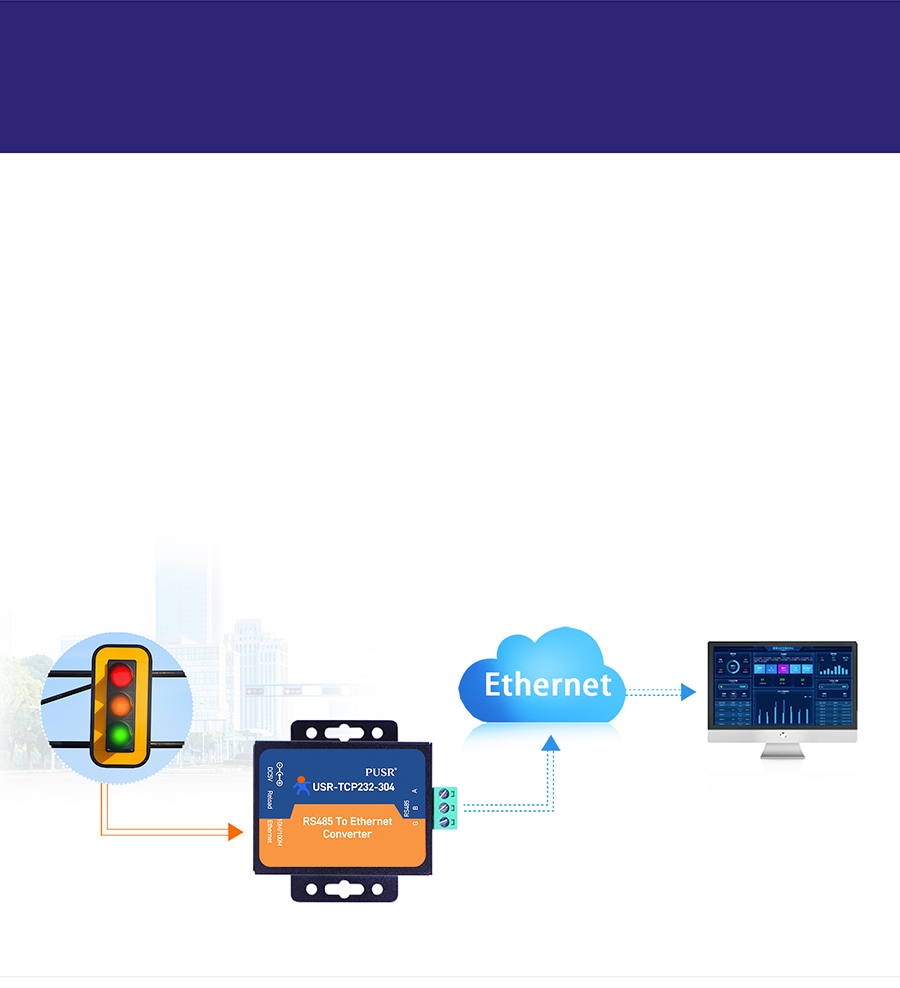

The RS485 to Ethernet technology is precisely the key to solving this problem. It converts the serial data of RS485 devices into TCP/IP packets that are recognizable by Ethernet through hardware converters, enabling cross-protocol communication. For example, an RS485-enabled sensor can be connected to a local area network via a converter, allowing a remote monitoring system to read its data in real-time without modifying the original equipment. This technology not only extends the lifespan of traditional equipment but also significantly reduces the deployment costs of industrial IoT.

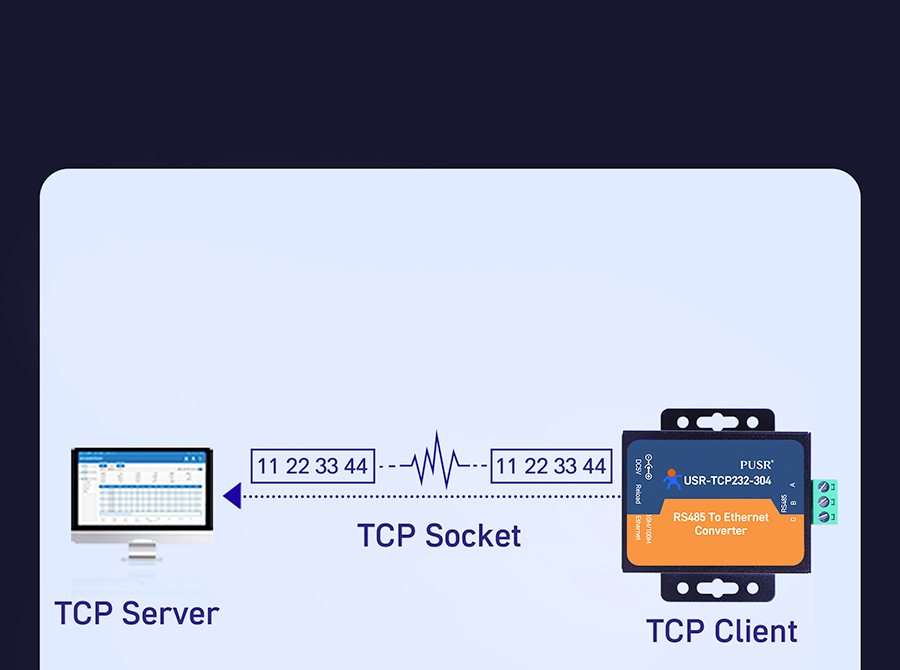

Taking the RS485 to Ethernet converter USR-TCP232-304 as an example, its core value lies in "transparent transmission"—devices do not need to modify their original protocols, and the converter automatically completes data format conversion to ensure data integrity and real-time performance. This feature makes it the preferred solution for connecting industrial field devices.

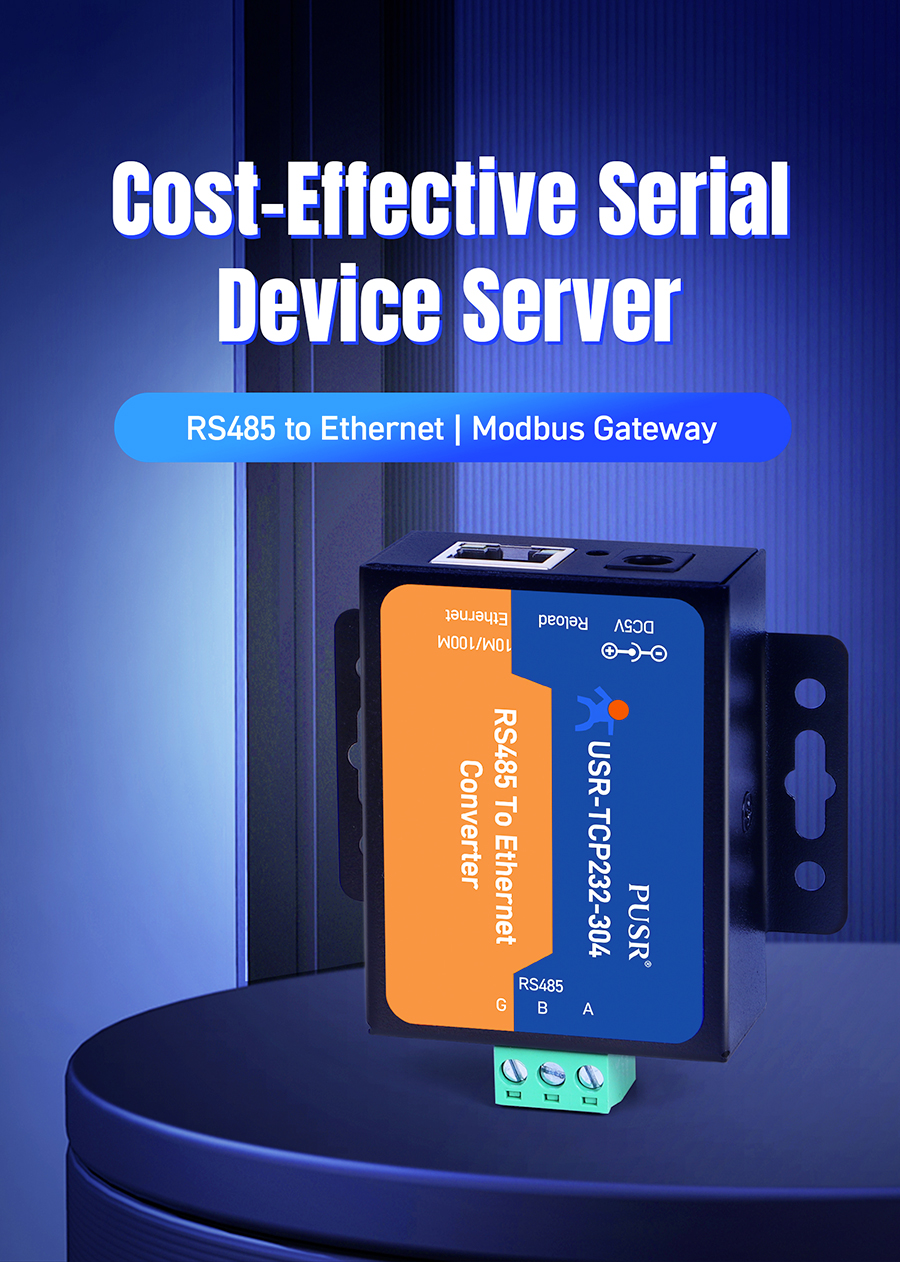

2. RS485 to Ethernet Converter USR-TCP232-304: A Compact, Low-Cost "All-Rounder"

2.1 Compact Design, Flexible Deployment

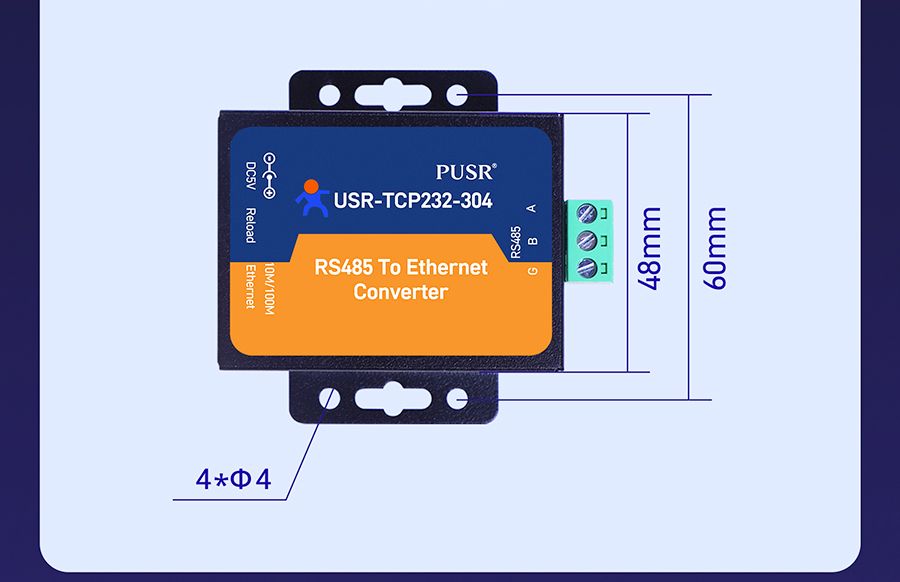

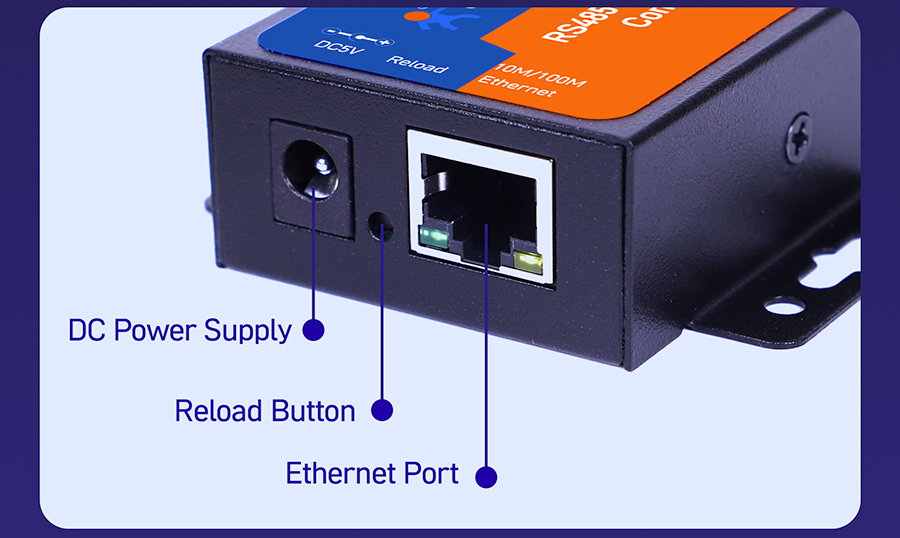

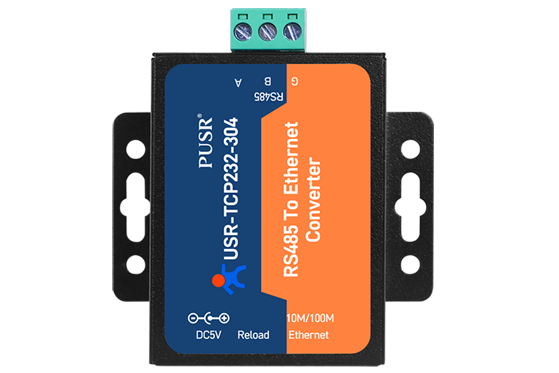

The RS485 to Ethernet converter USR-TCP232-304 features a miniature size of 76mm × 52mm × 22mm and weighs only 80g, allowing it to be easily embedded in confined spaces or mobile devices. Its DIN rail mounting design further simplifies cabinet deployment, making it particularly suitable for industrial sites with limited space. For instance, in the distribution boxes of intelligent buildings, the device can be concealed while connecting multiple RS485 meters to enable centralized collection of energy consumption data.

2.2 Cost Advantage, King of Cost-Effectiveness

Compared to similar products, the RS485 to Ethernet converter USR-TCP232-304 reduces prices by over 30% without compromising functionality. It supports 10/100Mbps adaptive Ethernet, is compatible with Modbus RTU/TCP protocols, and incorporates a built-in web server configuration interface, enabling users to set parameters without professional software. This "low-cost + high-integration" characteristic makes it an ideal choice for small and medium-sized enterprises undergoing industrial IoT transformation.

2.3 Typical Application Scenarios

Smart Factories: Connect RS485 devices such as PLCs and frequency converters to enable real-time upload of production data to MES systems.

Agricultural IoT: Deployed in greenhouses to network soil moisture sensors, CO₂ concentration meters, and other devices, supporting remote irrigation control.

Energy Management: Connect electricity and water meters to transmit data to cloud platforms via Ethernet, generating visual energy consumption reports.

3. Edge Computing: Enabling Devices to "Think"

3.1 Core Value of Edge Computing

The edge computing functionality of the RS485 to Ethernet converter USR-TCP232-304 completes data preprocessing, protocol conversion, and simple logical operations at the device level through its built-in processor. For example, on an automated production line, the converter can analyze sensor data in real-time and only upload alarm information when the temperature exceeds a threshold, rather than continuously transmitting massive amounts of raw data. This "data slimming" strategy significantly reduces network load and cloud server pressure.

3.2 Typical Application Scenarios

Predictive Maintenance: In wind turbine monitoring, the converter analyzes vibration data through edge algorithms to identify bearing wear in advance, avoiding unplanned downtime.

Local Decision-Making: In unattended pump stations, the converter can automatically start and stop pumps based on liquid level sensor data without cloud intervention.

Security Isolation: In financial outlets, the converter locally encrypts video surveillance data and only uploads summary information to protect sensitive data.

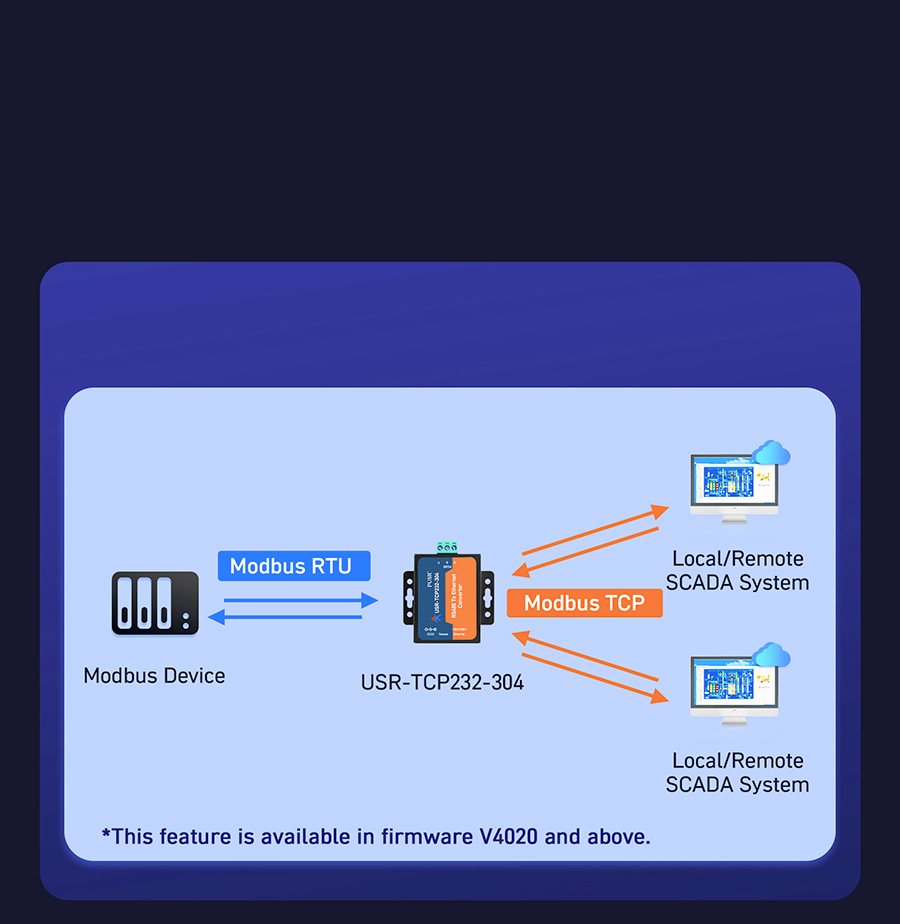

4. Modbus Gateway: Breaking Protocol Barriers

4.1 Compatibility Challenges of Modbus Protocol

Modbus is one of the most commonly used communication protocols in the industrial sector, but it exists in two versions: RTU (serial) and TCP (Ethernet). The Modbus gateway functionality of the RS485 to Ethernet converter USR-TCP232-304 enables seamless conversion between these two protocols. For example, an old device that only supports Modbus RTU can be directly connected to a SCADA system supporting Modbus TCP via the converter without replacing the hardware.

4.2 Typical Application Scenarios

Multi-Protocol Device Interconnection: In chemical plants, where Modbus RTU meters and TCP controllers coexist, the converter acts as a "protocol translator" for unified management.

Remote Debugging: Engineers can remotely modify parameters of Modbus RTU devices via Ethernet without on-site operations.

System Integration: In smart city projects, Modbus devices from different manufacturers are integrated into a unified platform to enhance data interoperability.

5. MQTT Protocol: The "Messenger" of Lightweight IoT

5.1 Advantages of MQTT in IoT

MQTT is a lightweight protocol based on the publish/subscribe model, designed for low-bandwidth, high-latency, or unreliable networks. The RS485 to Ethernet converter USR-TCP232-304 supports MQTT client functionality, allowing it to encapsulate RS485 device data into MQTT messages and transmit them globally via brokers (such as AWS IoT and Alibaba Cloud). For example, in the monitoring of oil and gas pipelines in remote areas, the converter can stably upload pressure data to the cloud via MQTT, ensuring data integrity even with frequent network interruptions.

5.2 Typical Application Scenarios

Mobile Asset Tracking: In logistics vehicles, the converter connects GPS modules to report location information in real-time via MQTT.

Large-Scale Device Management: In smart agriculture, thousands of soil sensors report data centrally via MQTT, enabling efficient processing by cloud platforms.

Low-Power Applications: In solar-powered field monitoring stations, the extremely small data packet size of MQTT extends device battery life.

6. Five Reasons to Choose the RS485 to Ethernet Converter USR-TCP232-304

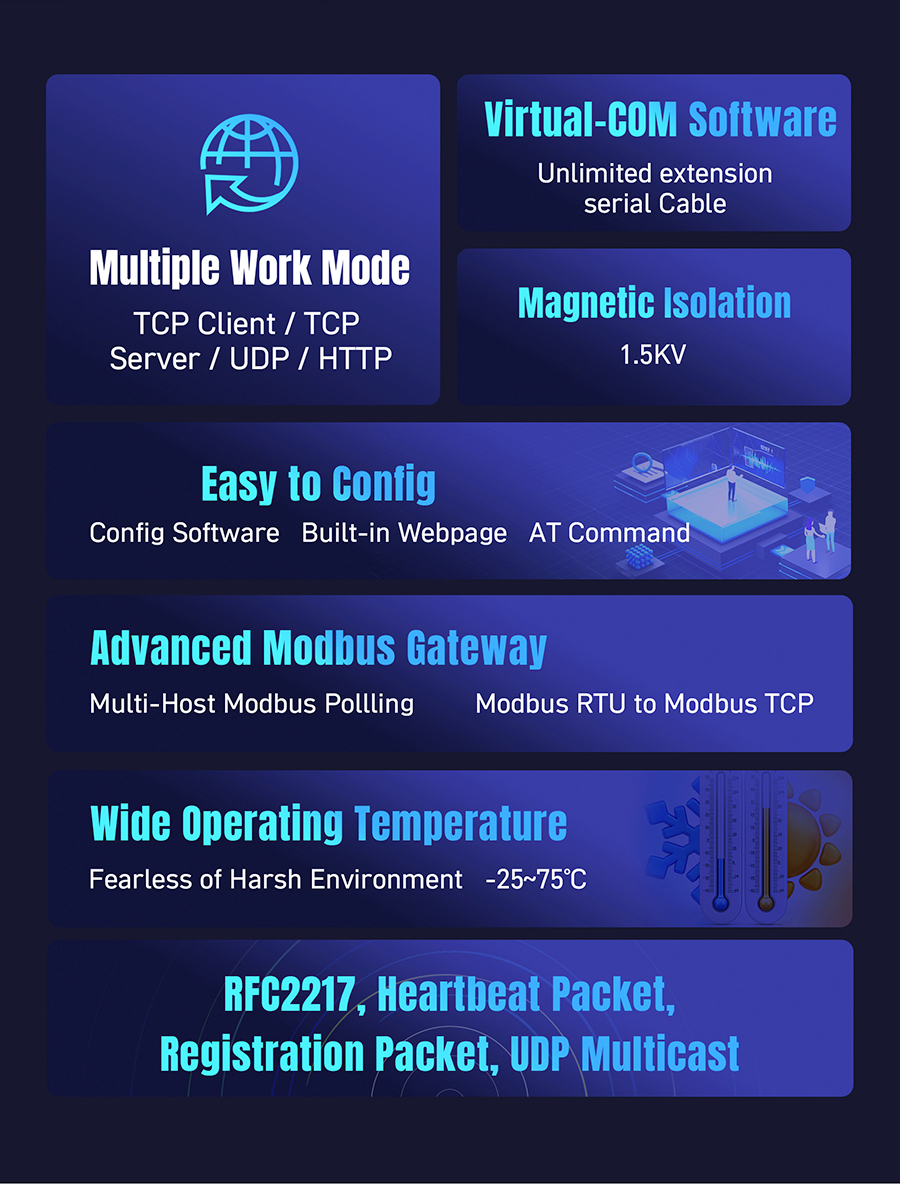

6.1 Full Protocol Support, Multi-Functional in One Device

It is compatible with RS485, Ethernet, Modbus, and MQTT, covering the complete link from field devices to cloud platforms. Users do not need to purchase multiple converters, reducing system complexity.

6.2 Industrial-Grade Reliability

Operating temperature range: -40°C to 85°C, suitable for extreme environments.

Electromagnetic compatibility (EMC) certification, strong anti-interference capability.

Isolated RS485 interface, protecting devices from surge damage.

6.3 Zero-Code Configuration, Rapid Deployment

Through a web interface or configuration tools provided by PUSR, users can set network parameters and protocol conversion rules within 5 minutes. Even non-professionals can easily get started.

6.4 Security Protection, Worry-Free Data

Supports TLS/SSL encryption to prevent data eavesdropping.

Hierarchical user permission management to avoid unauthorized operations.

Local data caching with automatic resumption during network interruptions.

6.5 Ecosystem Support, Continuous Evolution

PUSR provides comprehensive SDKs and APIs to support secondary development. Additionally, device firmware can be remotely upgraded to ensure functionality stays in sync with the latest technologies. For example, when the MQTT protocol is updated, users can obtain new features without replacing the hardware.

7. Customer Cases: From Laboratory to Large-Scale Deployment

Case 1: An Automobile Manufacturing Plant

The plant originally had over 200 RS485 welding robots, with data collection relying on manual inspections. After deploying the RS485 to Ethernet converter USR-TCP232-304, robot operating parameters were uploaded to the MES system in real-time, reducing fault response time from 2 hours to 10 minutes and lowering annual maintenance costs by 40%.

Case 2: A Smart Agriculture Project

In a 10,000-mu farm in Gansu, the converter connected soil moisture sensors, weather stations, and other devices to transmit data to Alibaba Cloud via MQTT. Farmers can precisely control irrigation systems through a mobile app, improving water resource utilization by 35%.

8. Why Choose PUSR's RS485 Over Ethernet USR-TCP232-304

The core reasons for selecting PUSR's RS485 Over Ethernet 304 lie in its high integration, protocol compatibility, edge computing capabilities, and industrial-grade reliability. It enables seamless integration of RS485 devices with modern networks at a low cost, meeting the data acquisition and remote management needs of complex industrial scenarios.

8.1 Compact Size and Low Cost: Adapt to Compact Deployments and Budget Control

Compact Design: The RS485 Over Ethernet 304 features a compact design, facilitating easy integration into space-constrained industrial equipment or control cabinets, reducing installation complexity.

Economy: Compared to traditional solutions (e.g., industrial PCs + serial cards), the RS485 Over Ethernet 304 achieves RS485-to-Ethernet conversion at a lower cost, making it particularly suitable for small- to medium-sized projects with limited budgets.

8.2 Protocol Compatibility and Communication Flexibility

Multi-Protocol Support:

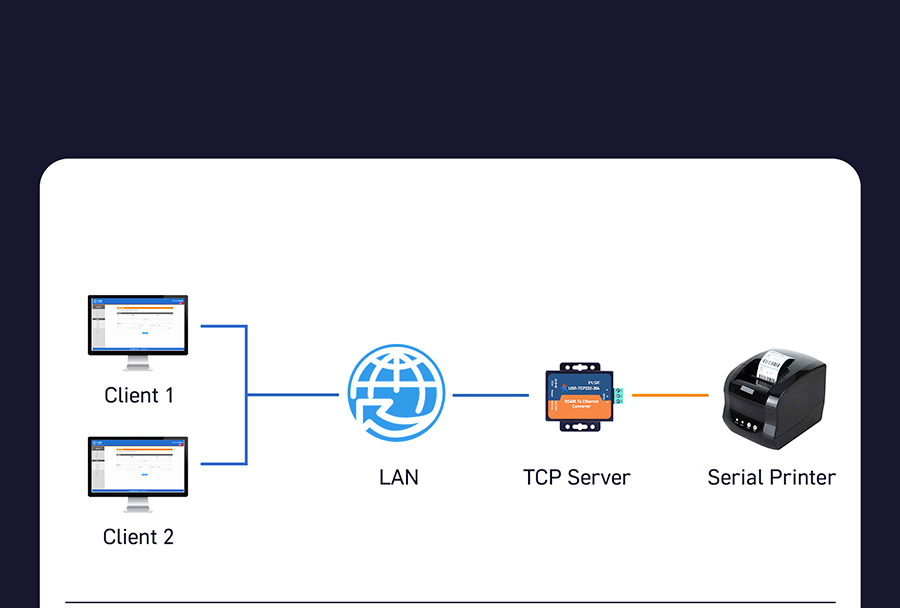

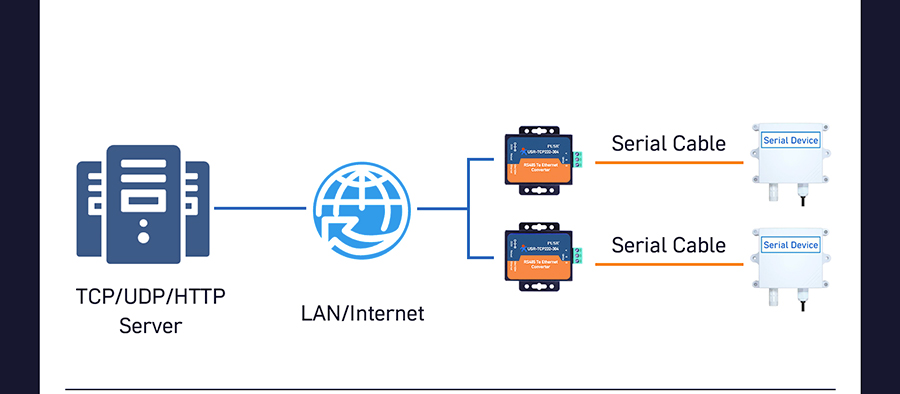

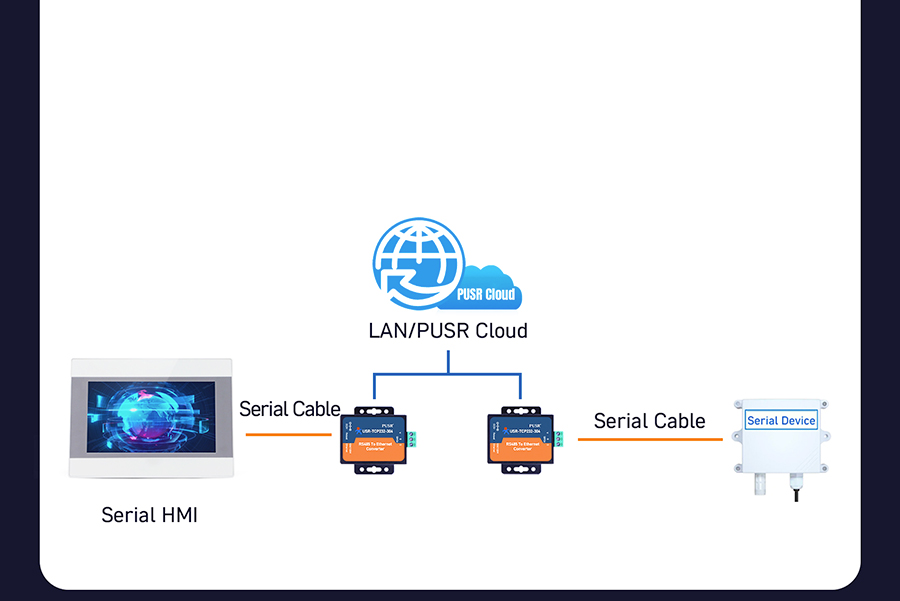

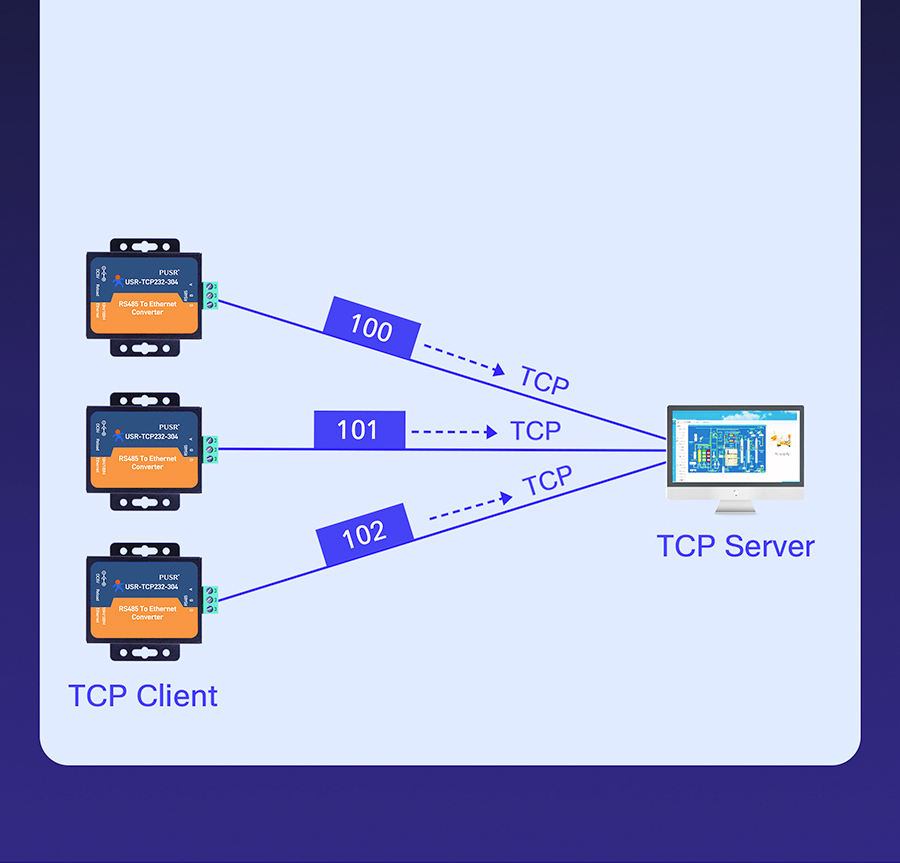

TCP/UDP Protocols: Supports multiple modes such as TCP Server, TCP Client, UDP Server, and UDP Client, adapting to diverse network architecture requirements.

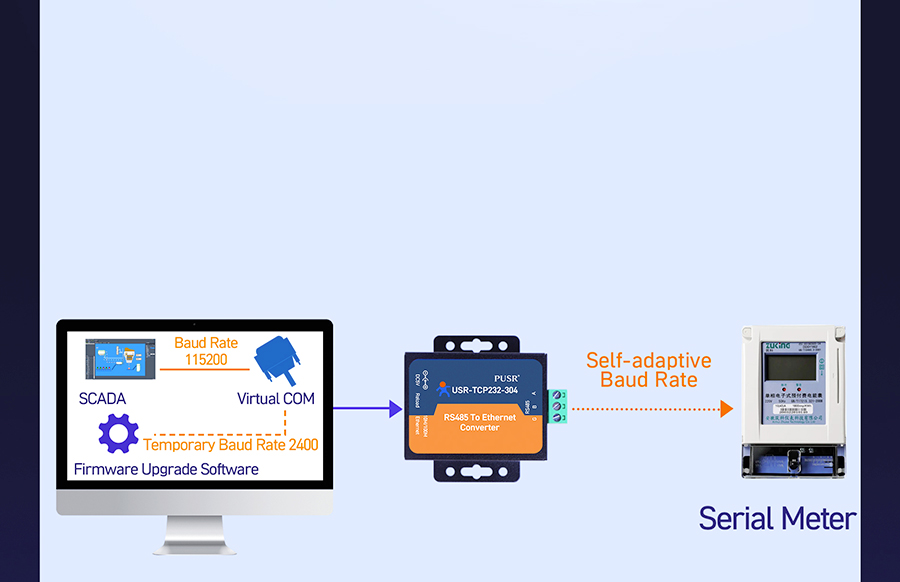

Modbus Gateway Functionality: Built-in Modbus RTU/TCP protocol conversion enables automatic polling of Modbus commands, seamless integration of PLCs, sensors, and other devices, and supports multi-host polling mechanisms (up to 20 devices).

MQTT Protocol: Supports lightweight MQTT protocol, allowing direct connection to IoT platforms like Alibaba Cloud, lowering the barrier to cloud integration.

Custom Protocol Expansion: Provides support for private protocols (TCP-ZSD, UDP-ZSD), optimized over 10 years for more stable operation.

8.3 Edge Computing Capabilities: Enhance Data Processing Efficiency

Local Data Processing: Built-in edge computing functionality enables preprocessing (e.g., JSON reporting), filtering, or simple analysis of data at the device level, reducing cloud transmission pressure.

Real-Time Response: Supports rapid acquisition of RS485 device data and proactive periodic command issuance via configuration software, meeting the real-time requirements of industrial automation.

Caching and Retransmission Mechanism: Built-in bidirectional data buffer ensures automatic data retransmission after network interruptions, preventing data loss.

8.4 Industrial-Grade Reliability: Withstand Harsh Environments

Electrical Protection: Features ISO9001 international quality certification, supports 5-36V wide voltage power supply, and employs a three-level watchdog mechanism (software + hardware + CPU) to ensure 7×24 stable operation.

Environmental Adaptability: Operates in extreme temperatures ranging from -40℃ to 85℃, meeting outdoor or industrial field requirements.

Noise Immunity: The RS485 interface utilizes balanced drivers and differential receivers, offering strong resistance to noise interference and enabling transmission distances up to 3000 meters (at 9600bps).

8.5 Convenient Configuration and Management

Multi-Parameter Configuration Methods: Supports various configuration methods such as WEB pages, Chrome browsers, serial protocols, and network protocols, reducing debugging difficulty.

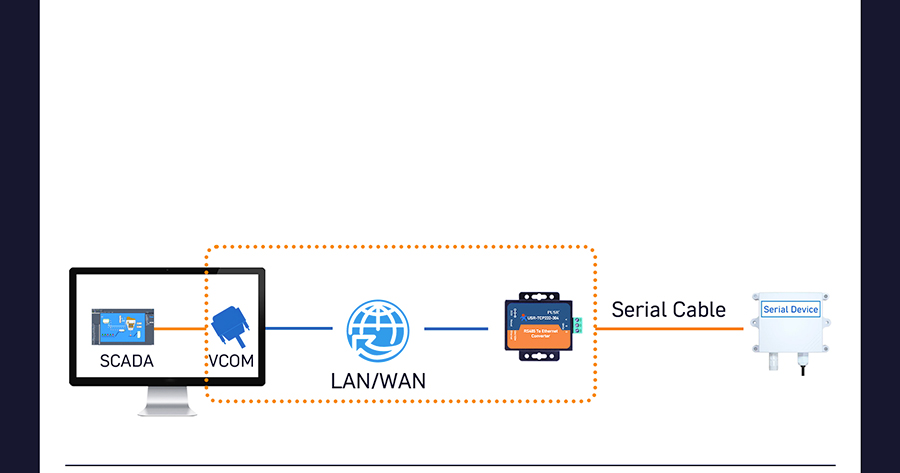

Virtual Serial Port Support: Maps network data to virtual serial ports via the (accompanying) USR-VCOM software, ensuring compatibility with traditional PC-side serial software (e.g., KingView, ForceControl).

Remote Management: Supports DHCP and DNS dynamic domain name resolution, enabling server connection without fixed IPs and simplifying network deployment.

8.6 Typical Application Scenarios

Industrial Automation: Connect RS485 devices such as PLCs and frequency converters for remote monitoring and centralized management.

Energy Management: Integrate smart meters, photovoltaic inverters, and other devices to collect data via Modbus polling and upload it to the cloud.

Environmental Monitoring: Connect temperature and humidity sensors, gas detectors, and other devices for real-time data acquisition and abnormal alerts.

Retail and Logistics: Integrate POS machines, barcode scanners, and other devices to enable real-time sales data upload via Ethernet.

The PUSR RS485 Over Ethernet USR-TCP232-304 is not just an RS485-to-Ethernet converter but also an "intelligent bridge" for the Industrial Internet of Things (IIoT). With its compact size, low cost, and high compatibility, it addresses the pain points of connecting traditional devices to networks. Through edge computing, Modbus gateway functionality, MQTT protocol support, and other features, it empowers devices with local decision-making and cloud collaboration capabilities. For enterprises seeking cost-effective digital transformation, the RS485 Over Ethernet 304 is undoubtedly one of the most cost-effective choices available.