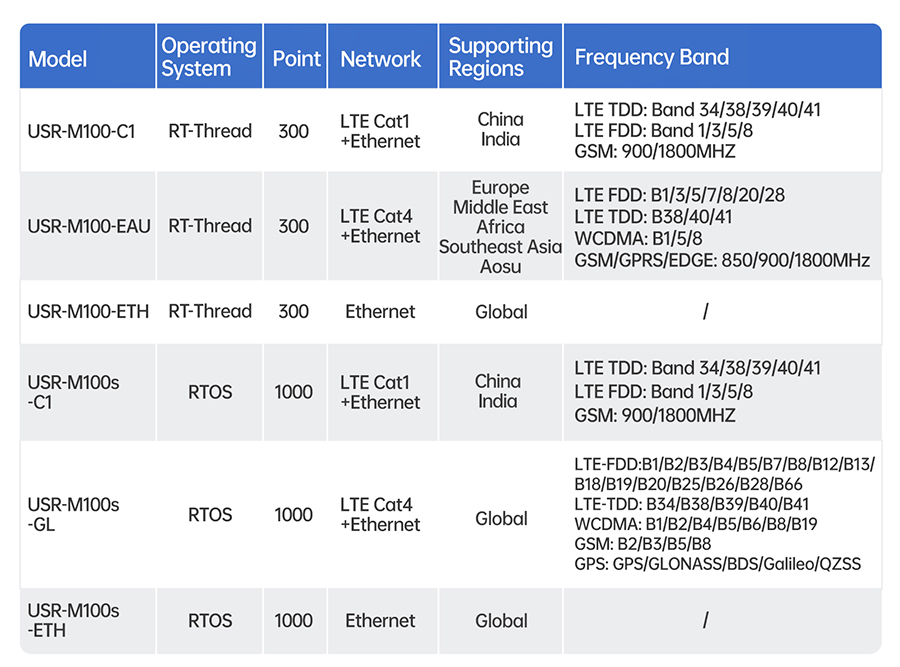

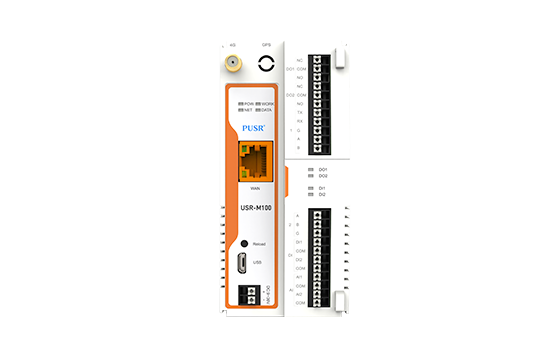

Amid the wave of deep integration between Industry 4.0 and the Internet of Things (IoT), enterprises face core pain points such as high data acquisition latency, overloaded cloud workloads, and strong network dependency. The IoT edge gateway device USR-M100 launched by PUSR has become a critical hub for data intelligence in industrial settings, thanks to its innovative design featuring a "building-block architecture, edge computing, and full protocol compatibility."

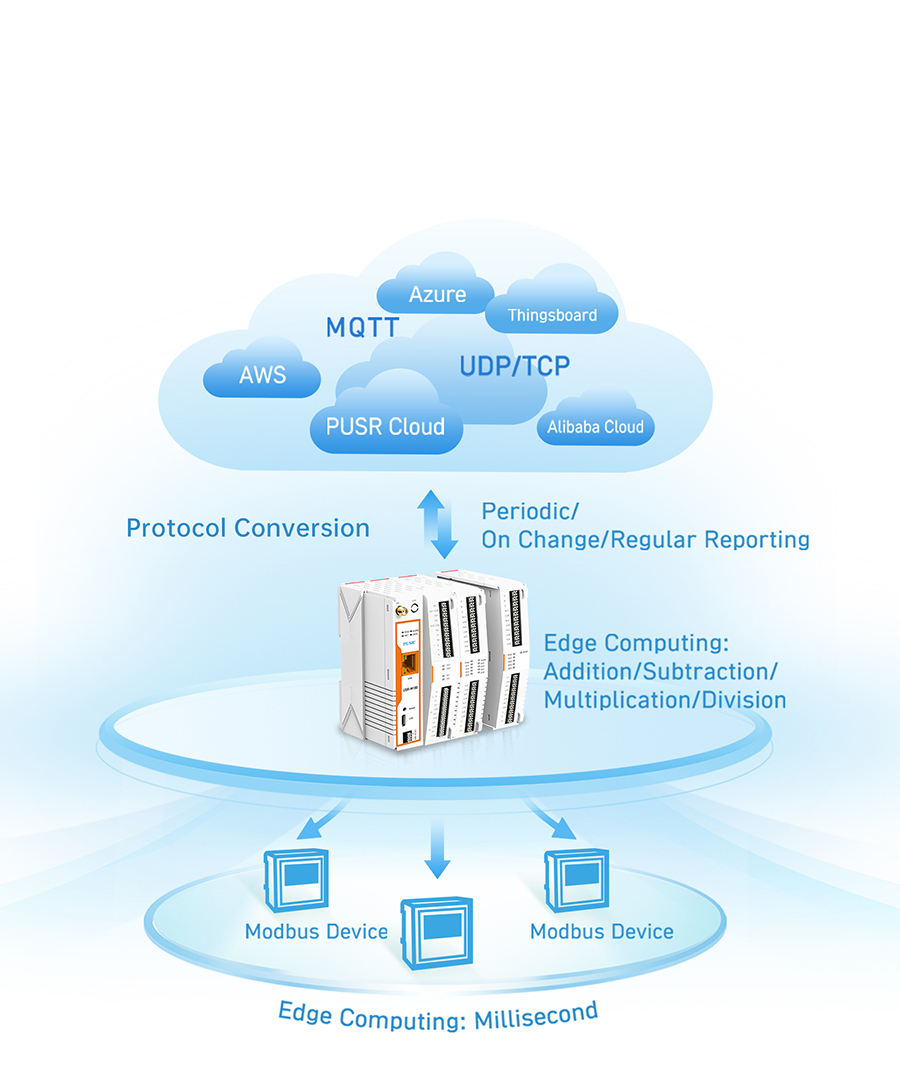

1. What is Edge Computing Functionality?

1.1 Core Functions of Edge Computing

The IoT gateway device M100 is equipped with a Cortex-M7 core (400MHz clock speed) that supports localized data acquisition, computation, and decision-making. Its edge computing capabilities deliver three core values:

Enhanced Real-time Performance: By processing data locally, industrial control response times are shortened from seconds to milliseconds. For example, in an automotive parts production line, its local FFT analysis function reduces vibration anomaly detection latency from 60 cloud-based polls per minute to just 5, boosting response speed by 12 times.

Bandwidth Optimization: Only critical or anomalous data is uploaded, reducing network traffic by over 70%. In power distribution room monitoring scenarios, its "change reporting" feature triggers data uploads only when current fluctuations exceed 5%. A single gateway can manage over 200 electricity meters, cutting operational costs by 40%.

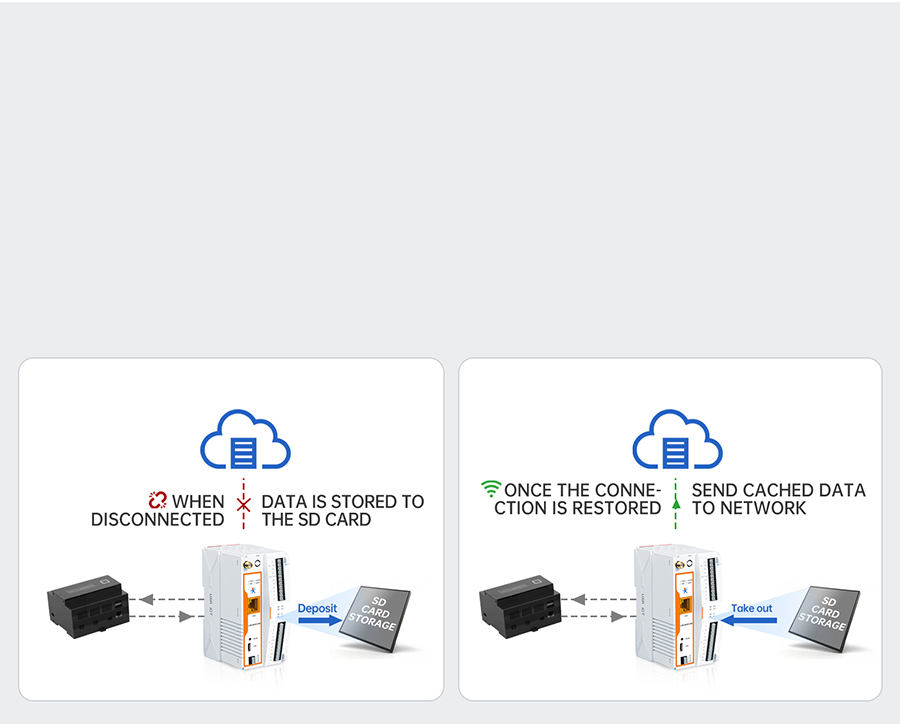

Improved Reliability: The device operates independently during network outages, ensuring production continuity. Its offline data caching and automatic resumption upon network recovery guarantee data integrity.

1.2 Value for Enterprises

Cost Efficiency and Productivity Gains: Edge computing reduces cloud computing resource consumption, lowering IT costs. For instance, after deploying the IoT gateway device M100, a smart factory saw a 60% reduction in cloud server load and annual operational savings exceeding one million yuan.

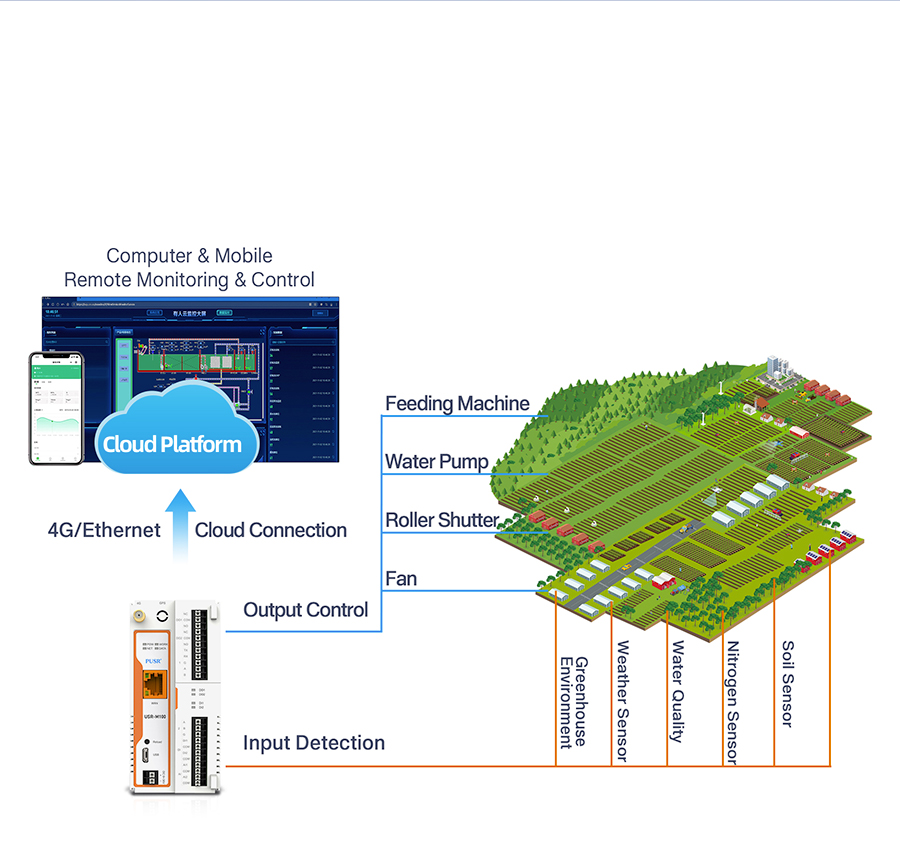

Production Transparency: Localized data aggregation and analysis enable real-time equipment monitoring and predictive maintenance. In agricultural irrigation scenarios, its built-in PID algorithm dynamically adjusts solenoid valves based on soil moisture, improving water efficiency by 30% and reducing irrigation response latency from 15 seconds to 200 milliseconds.

Security Enhancement: Sensitive data is desensitized locally, reducing transmission leakage risks. Supporting TLS1.2 encryption and bidirectional certificate authentication, it meets Level 2.0 security requirements, providing a robust security barrier for industrial control systems.

2. Comprehensive Coverage: Six Core Application Scenarios for IoT Gateway Device M100

2.1 Industrial Automation: From Equipment Monitoring to Intelligent Decision-Making

Scenario Pain Points: Traditional PLC data acquisition relies on cloud polling, resulting in high latency and bandwidth consumption.

Solution: The IoT gateway device M100 directly collects PLC data via RS485/232 interfaces, performs local logic operations (e.g., threshold judgment, unit conversion), and uploads only anomalous data to the MES system. In an automotive parts production line, its edge acquisition function reduced cloud polling frequency from 60 times per minute to 5, cutting network load by 90%.

Core Value: Achieves synergy between device-level real-time control and cloud-level data analysis, enhancing production flexibility.

2.2 Smart Agriculture: Precision Irrigation and Environmental Control

Scenario Pain Points: Scattered environmental data collection in farmland and high irrigation system response latency.

Solution: The IoT gateway device M100 integrates soil moisture sensors (4-20mA) and weather station (Modbus RTU) data, dynamically adjusting solenoid valves via built-in PID algorithms. In a smart farm in Shandong, its edge computing functionality shortened irrigation response latency to 200 milliseconds and improved water efficiency by 30%.

Core Value: Reduces reliance on the cloud through localized decision-making, adapting to weak network environments.

2.3 Energy Management: Intelligent Monitoring of Power Distribution Rooms

Scenario Pain Points: Manual inspection-based electricity meter data collection and slow fault response.

Solution: The IoT gateway device M100 supports SNMP protocol and triggers data uploads only when current fluctuations exceed 5% via its "change reporting" feature. Combined with dual-network redundancy (Ethernet + 4G Cat1), it enables centralized management of over 200 electricity meters. In a Southern Power Grid substation, its application reduced operational costs by 40% and shortened fault localization time to minutes.

Core Value: Lowers data transmission volume through edge computing, enhancing system reliability.

2.4 Smart Home: Localized Linked Control

Scenario Pain Points: Cloud-based control's network dependency and high privacy leakage risks.

Solution: The IoT gateway device M100 supports localized point linkage (e.g., automatic air conditioner activation when temperature and humidity exceed thresholds) without cloud intermediation. In a smart community, its edge computing functionality shortened alarm response time for abnormal door/window sensor openings to 100 milliseconds, storing user privacy data locally and improving security threefold.

Core Value: Enhances user experience through localized decision-making and meets privacy compliance requirements.

2.5 Logistics and Warehousing: Environmental Monitoring and Equipment Management

Scenario Pain Points: Manual inspection-based warehouse temperature and humidity monitoring and delayed equipment fault detection.

Solution: The IoT gateway device M100 integrates temperature and humidity sensors with AI cameras, enabling automatic temperature anomaly alarms and shelf tilt detection via edge computing. In a JD Logistics warehouse, its application reduced cargo damage rates by 25% and shortened equipment fault detection time to 5 minutes.

Core Value: Improves warehousing operational efficiency through localized data analysis.

2.6 Smart City: Intelligent Traffic Signal Control

Scenario Pain Points: Traditional signal control's reliance on fixed timing sequences, unable to dynamically respond to traffic flow.

Solution: The IoT gateway device M100 collects traffic flow data via cameras and dynamically adjusts signal timings using local PID algorithms. In a Shenzhen intersection pilot, its application reduced traffic congestion index by 18% and vehicle waiting time by 30%.

Core Value: Achieves real-time optimization of urban traffic through edge computing.

3. Core Function Analysis: The Technological Moat of IoT Edge Gateway M100

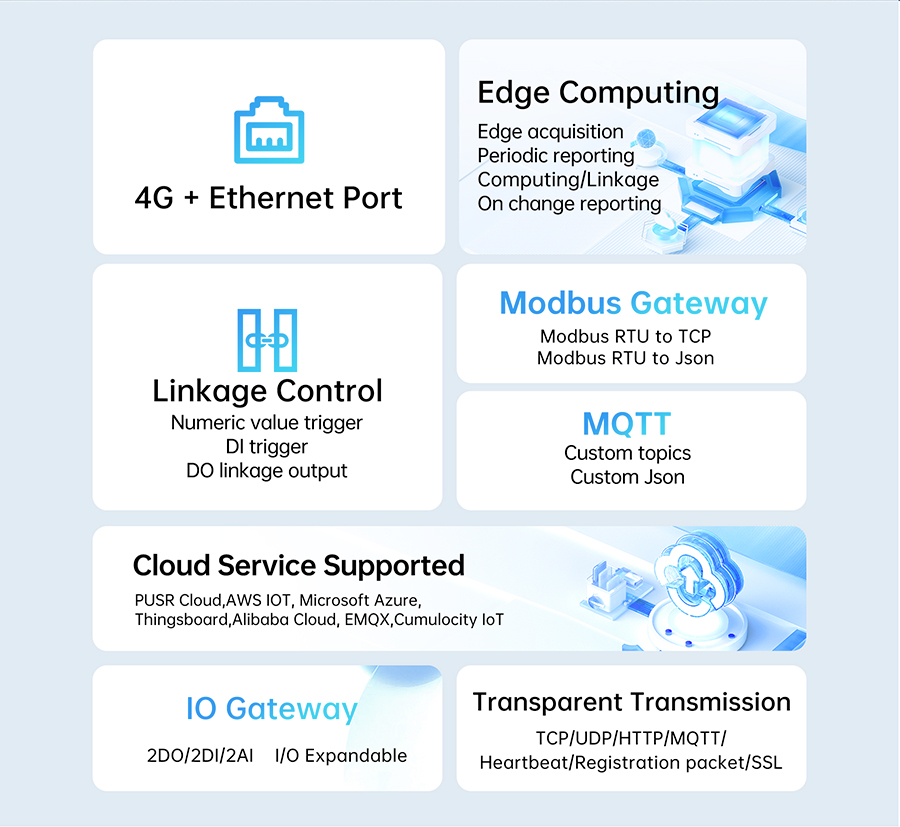

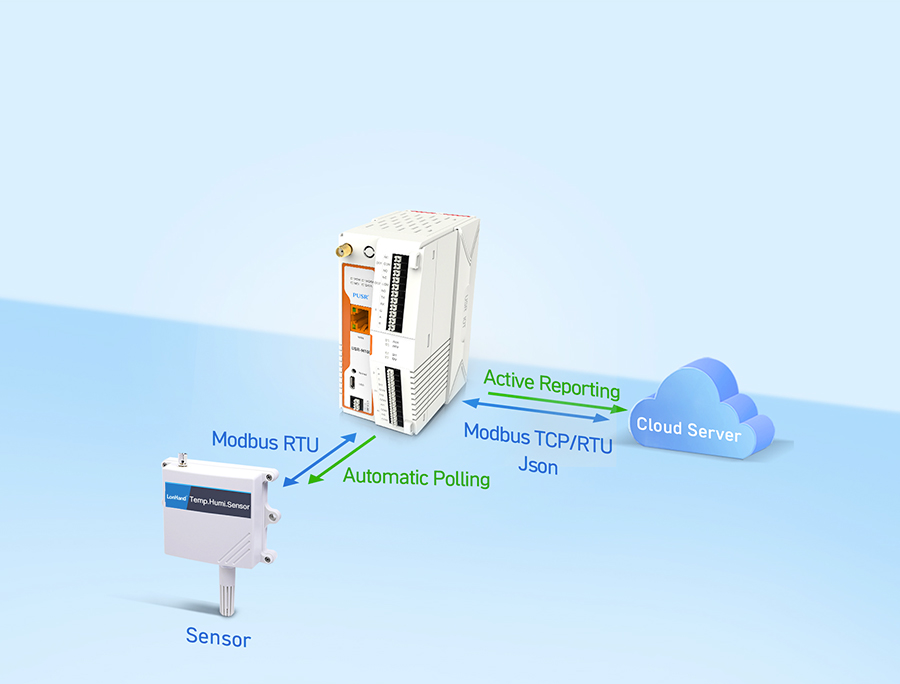

3.1 MQTT Data Uploading to the Cloud: Lightweight Protocol for Industrial Applications

Function: Converts traditional protocols like Modbus and HTTP into MQTT format, enabling seamless device-to-cloud platform integration. It supports TLS1.2 encryption and bidirectional certificate authentication for secure data transmission.

Technical Advantages:

Low Bandwidth Consumption: The MQTT protocol header is only 2 bytes, suitable for resource-constrained industrial devices.

High Reliability: Supports QoS levels (0/1/2) to ensure reliable message transmission.

Asynchronous Communication: The publish/subscribe model decouples devices, enhancing system scalability.

Suitable Environments: Weak network environments (e.g., remote farmland, underground tunnels) and large-scale device access scenarios (e.g., smart factories, smart cities)

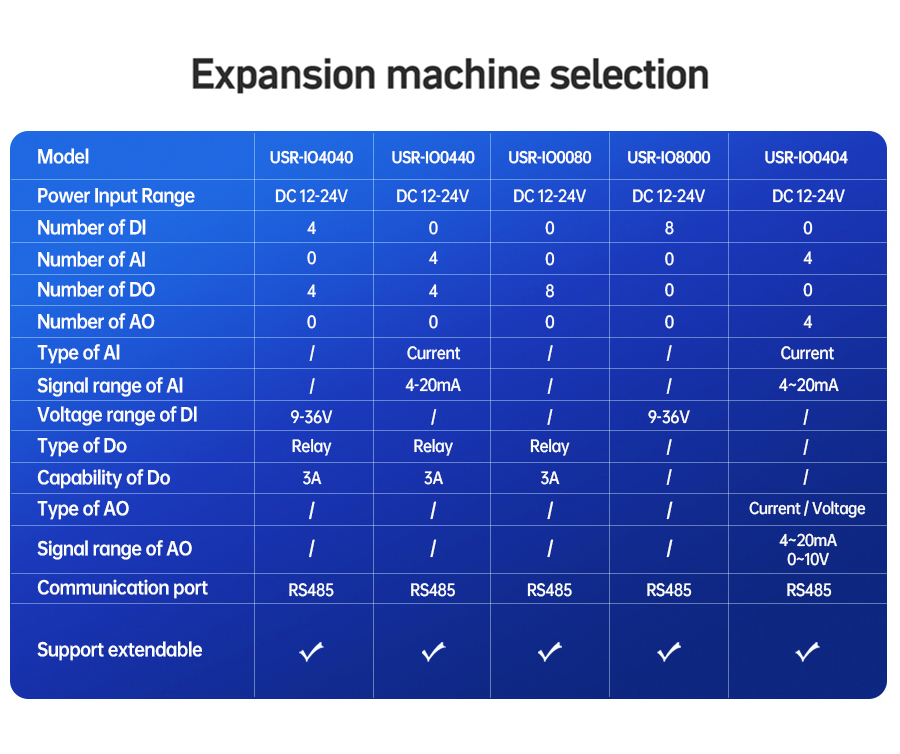

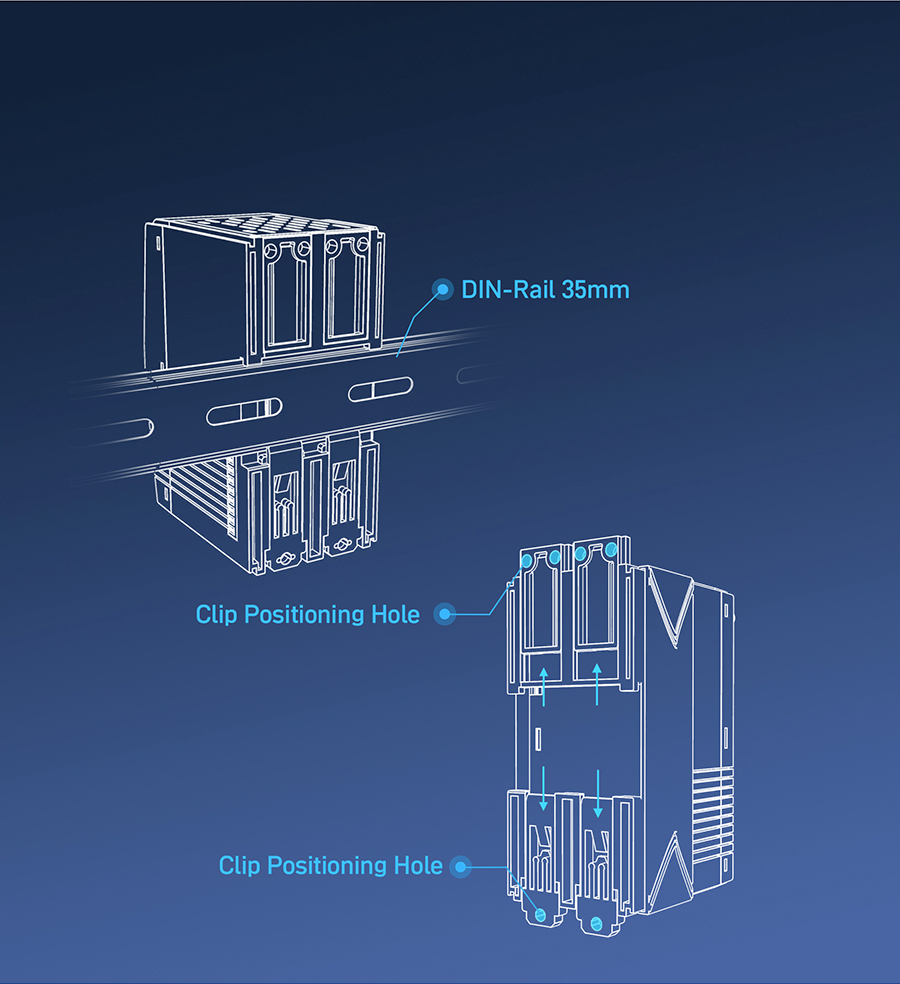

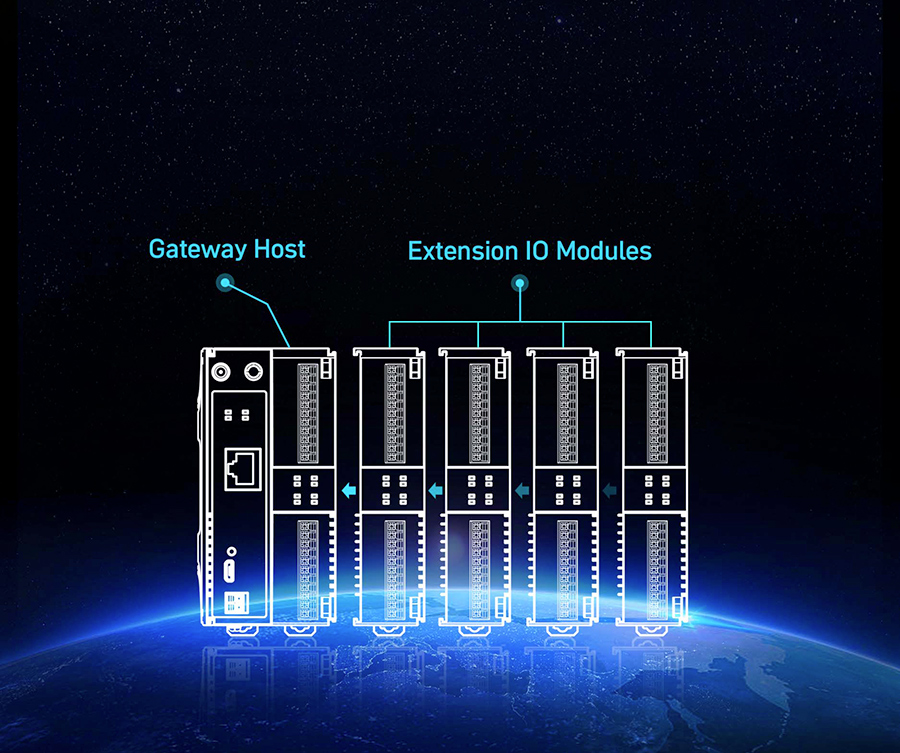

3.2 Expandable IO Gateway: Cost Advantages of Modular Design

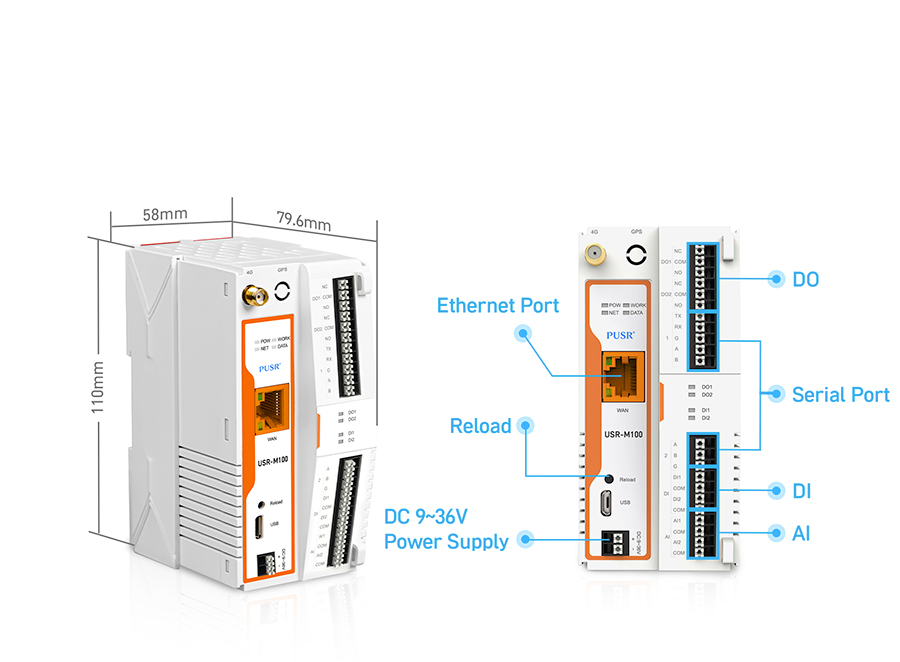

Function: The base version integrates 2DI/2DO/2AI and supports flexible IO point expansion via extension panels (up to 16DI/16DO/8AI) without replacing the entire unit.

Application Scenarios:

Production Line Upgrades: An electronics factory added temperature monitoring points by expanding 2 AI modules, saving 60% in equipment procurement costs.

Smart Agriculture: A farm added soil pH monitoring by expanding 1 AI module for data collection, avoiding full gateway replacement.

Core Value: Reduces total cost of ownership (TCO) through modular design, adapting to dynamic industrial site requirements.

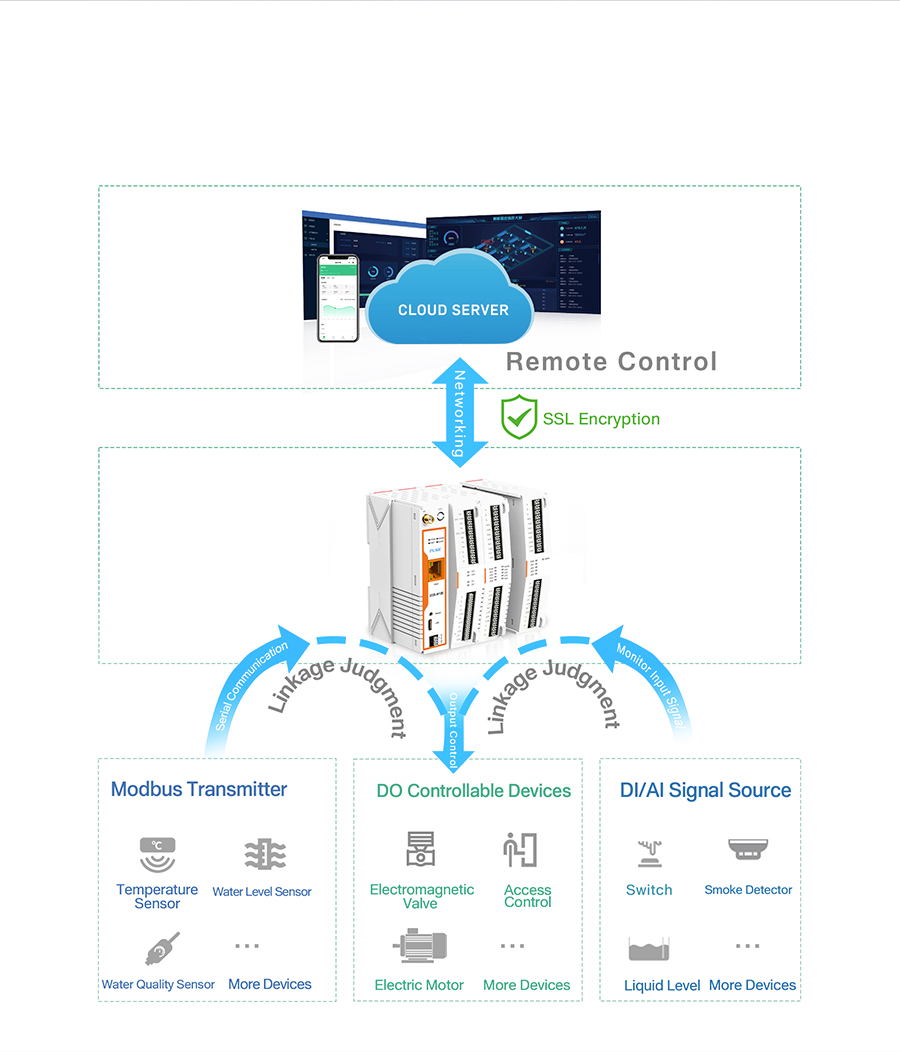

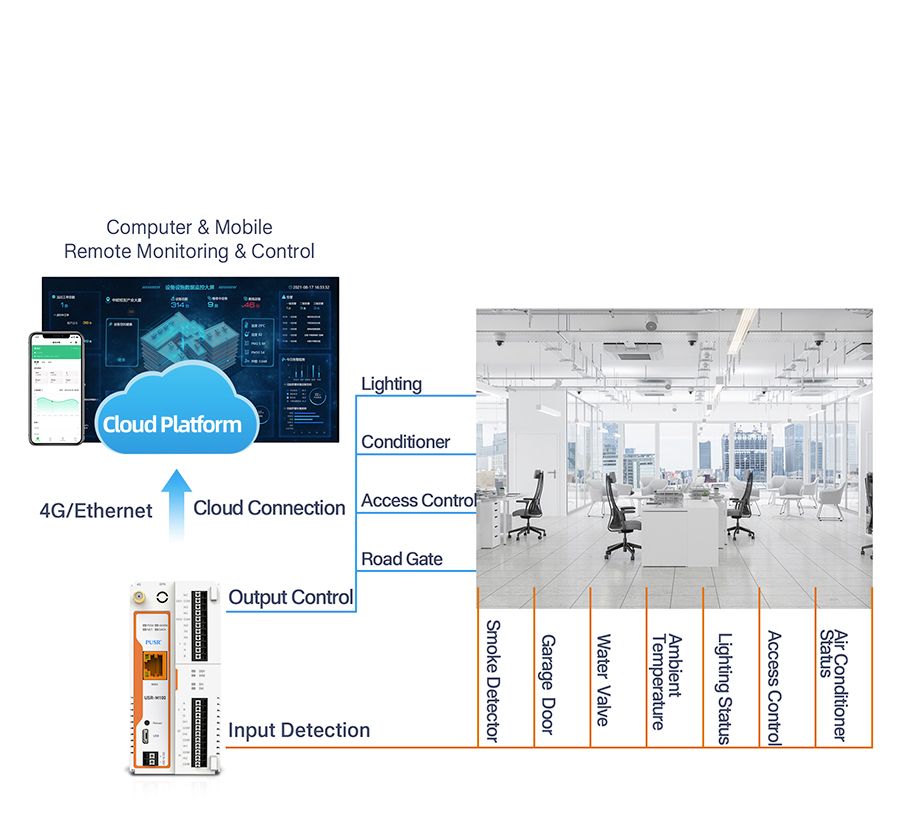

3.3 Point Linkage and Cloud Remote Control: Synergy Between Localization and Remote Management

Function:

Point Linkage: Supports 10 groups of event-driven DO control (e.g., automatic fan activation when temperature exceeds thresholds).

Cloud Remote Control: Enables device remote configuration and firmware upgrades via platforms like USR Cloud and Alibaba Cloud.

Application Scenarios:

Industrial Control: When a chemical plant's reactor temperature exceeds limits, local linkage cuts off the heating circuit while cloud alerts are pushed to managers' phones.

Smart Home: Users remotely view home temperature and humidity via a mobile app and set an "away mode" to automatically turn off the air conditioner.

Core Value: Balances localized rapid response with centralized remote management.

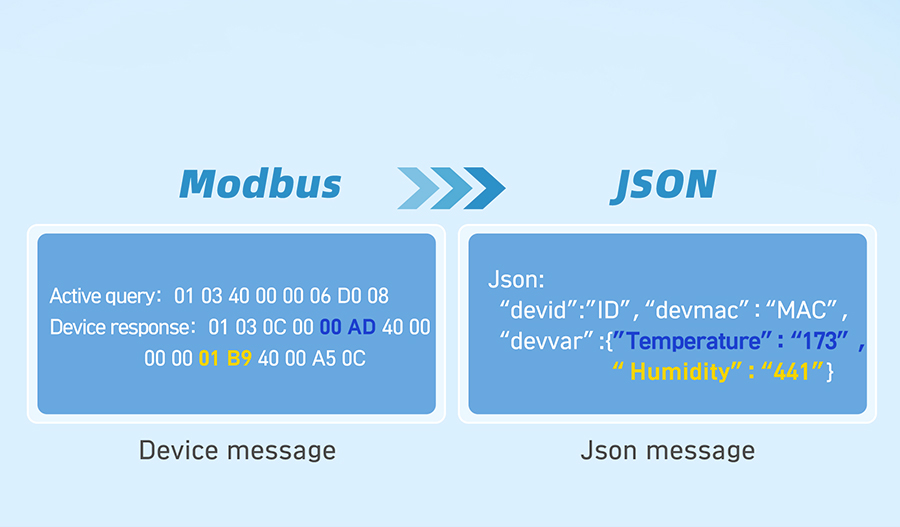

3.4 Modbus Gateway and Custom JSON: Protocol Compatibility and Data Standardization

Function:

Modbus Gateway: Supports Modbus RTU/TCP protocol conversion, compatible with mainstream PLCs like Siemens and Mitsubishi.

Custom JSON: Allows custom data reporting formats, compatible with over 90% of third-party platforms.

Application Scenarios:

Legacy Equipment Upgrades: A factory's existing Modbus RTU devices accessed the Alibaba Cloud platform via the IoT edge gateway M100 without replacement.

Multi-platform Integration: A smart park simultaneously accessed USR Cloud, Tencent Cloud, and Huawei Cloud, using custom JSON formats for unified data reporting.

Core Value: Breaks protocol barriers and reduces system upgrade costs.

4. Why Choose the Edge Computing IoT Gateway M100? Five Core Advantages

High-Performance Computing: Cortex-M7 core + 400MHz clock speed supports local execution of complex algorithms.

Full Protocol Compatibility: Supports over 20 industrial protocols like Modbus and OPC UA, covering over 90% of industrial equipment.

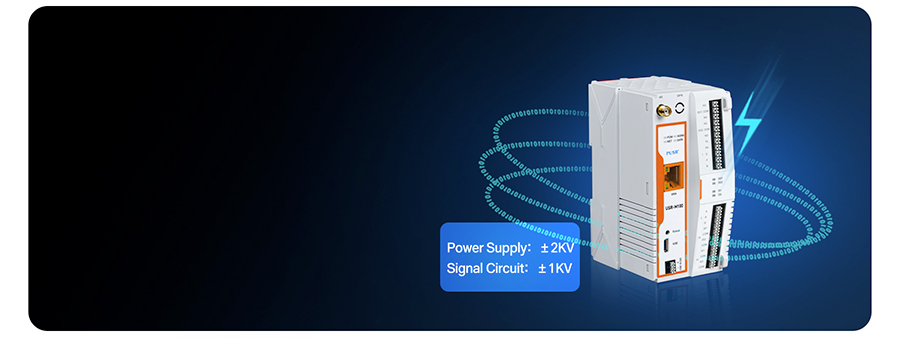

High Reliability Design: Features hardware/software watchdogs, surge protection (Level 3), and electrostatic discharge protection (Level 3), operating in -25°C to +75°C environments.

Ease of Use: Web-based debugging interface, point table import/export (CSV support), and customizable JSON templates lower deployment barriers.

Open Ecosystem: Embedded protocol stacks for platforms like USR Cloud, Alibaba Cloud, and AWS, supporting secondary development with open-source tools like Open62541 and Node-RED.

A Benchmark for Industrial Intelligence in the Edge Computing Era

The edge computing IoT gateway M100 redefines industrial IoT gateway technology standards with its core architecture of "edge computing, protocol compatibility, and modular design." From real-time quality control in automotive parts production lines to precision irrigation in smart agriculture, and from intelligent monitoring in power distribution rooms to localized linkage in smart homes, the edge computing IoT gateway M100 is becoming the "nerve center" of industrial site data intelligence. In today's era of deep integration between Industry 4.0 and IoT, choosing the edge computing IoT gateway M100 is not just selecting a product but embracing a future-oriented path to intelligent transformation.