In the era of rapid development of Industry 4.0 and the Internet of Things (IoT), interconnection among devices and efficient data transmission have become core requirements. However, traditional industrial equipment mostly adopts serial communication (such as RS232 and RS485), while modern network environments are mainly based on Ethernet (TCP/IP). How to achieve seamless integration between the two has become a key issue. PUSR's USR-TCP232-410s, as a high-performance Serial to Ethernet Converter, has become an ideal communication solution in fields such as industrial automation, smart cities, and energy management, thanks to its multi-protocol support, edge computing capabilities, secure encryption, and other features.

1. What is a Serial to Ethernet Converter?

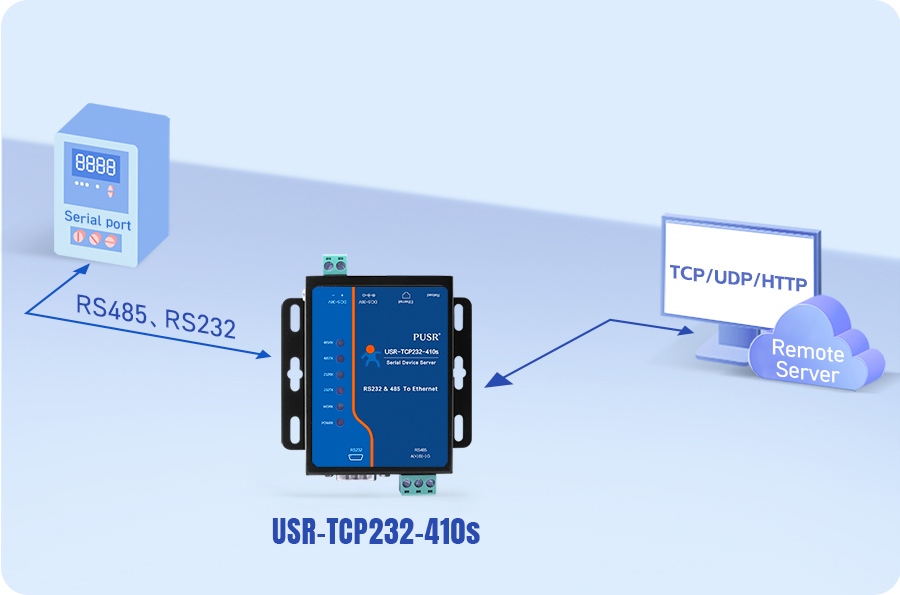

A Serial to Ethernet Converter is a hardware device used to convert traditional serial communication interfaces (such as RS232 and RS485) into Ethernet communication based on the TCP/IP protocol. Its core value lies in breaking down communication barriers between devices, enabling industrial equipment that only supports serial protocols (such as PLCs, sensors, and meters) to access local area networks or the Internet for remote monitoring, data acquisition, and centralized management.

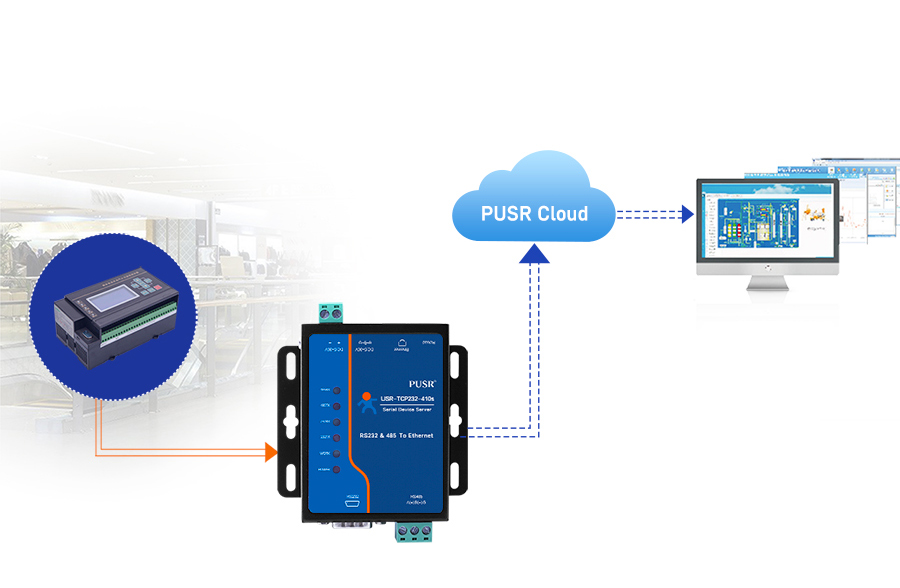

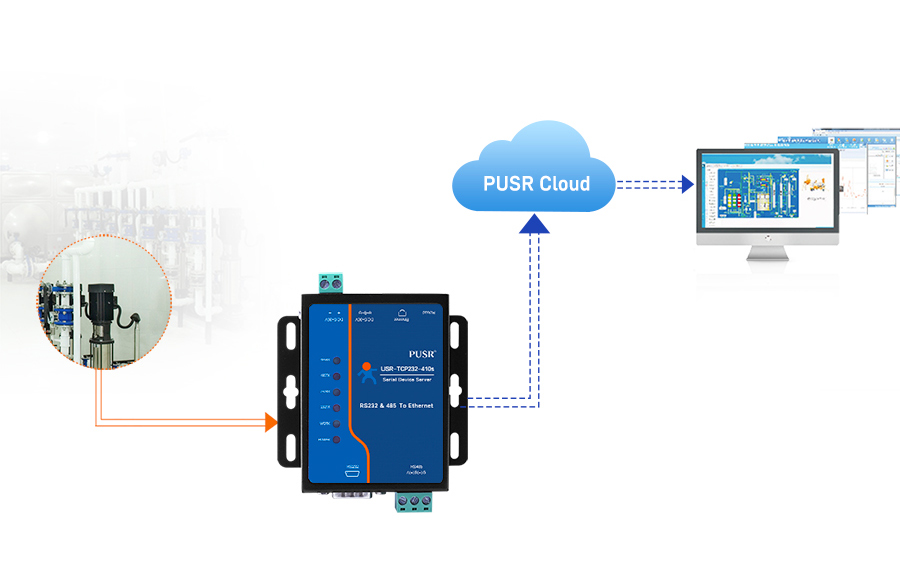

Taking the USR-TCP232-410s as an example, it encapsulates serial data into network packets through its built-in TCP/IP protocol stack and supports virtual serial port functionality, allowing host computer software to access serial devices via Ethernet without modification. This "transparent transmission" mode significantly reduces the difficulty of system integration and has become a key component in industrial IoT transformations.

2. Functions and Roles of Serial to Ethernet Converters

2.1 Protocol Conversion and Network Expansion

The Serial to Ethernet Converter 410s supports dual serial ports (RS232 and RS485), enabling simultaneous connection to devices with different protocols and access to local area networks or cloud platforms through an Ethernet interface. For example, in a factory, a PLC controls a production line via RS485, while the Serial to Ethernet Converter 410s converts its data into the TCP/IP protocol for real-time analysis by a remote server.

2.2 Multi-device Networking and Centralized Management

Through virtual serial port technology, a single PC can simultaneously manage multiple Serial to Ethernet Converter 410s devices, with each device corresponding to an independent virtual serial port, enabling centralized monitoring of distributed devices. This is particularly practical in smart building systems for unified management of subsystems such as air conditioning, lighting, and security.

2.3 Cross-platform Compatibility

It supports operating systems such as Windows, Linux, and Android, and is compatible with multiple modes including Modbus RTU/TCP and transparent transmission, adapting to industrial equipment from different manufacturers.

3. RS485 + RS232 Dual Serial Port Design: Unique Advantages and Application Scenarios of the 410s

The Serial to Ethernet Converter 410s innovatively integrates dual serial ports (RS485 and RS232) and supports simultaneous operation of both interfaces. This design addresses the pain point of frequent interface switching in traditional converters and is particularly suitable for the following scenarios:

3.1 Mixed Protocol Device Access

In energy management systems, electricity meters may use RS485 (long-distance, multi-node), while temperature and humidity sensors use RS232 (short-distance, point-to-point). The Serial to Ethernet Converter 410s can connect to both types of devices simultaneously, converting data into TCP/IP for transmission to a monitoring platform.

3.2 Cascading Communication and Redundancy Design

RS485 supports multi-device cascading (up to 128 nodes), while RS232 can be used for local debugging or backup channels. For example, in a wastewater treatment plant, the main controller connects to multiple sensors via RS485 and accesses a local HMI (human-machine interface) via RS232, ensuring system reliability.

3.3 Balancing Long-distance and High-speed Transmission

RS485 has a transmission distance of up to 1200 meters, suitable for outdoor or large factory buildings; RS232 offers higher transmission rates (up to 115.2 kbps), suitable for high-speed data acquisition scenarios. The dual-interface design of the Serial to Ethernet Converter 410s allows flexible task allocation to optimize system performance.

4. Why is USRT-TCP232-410S called "Modbus Gateway"

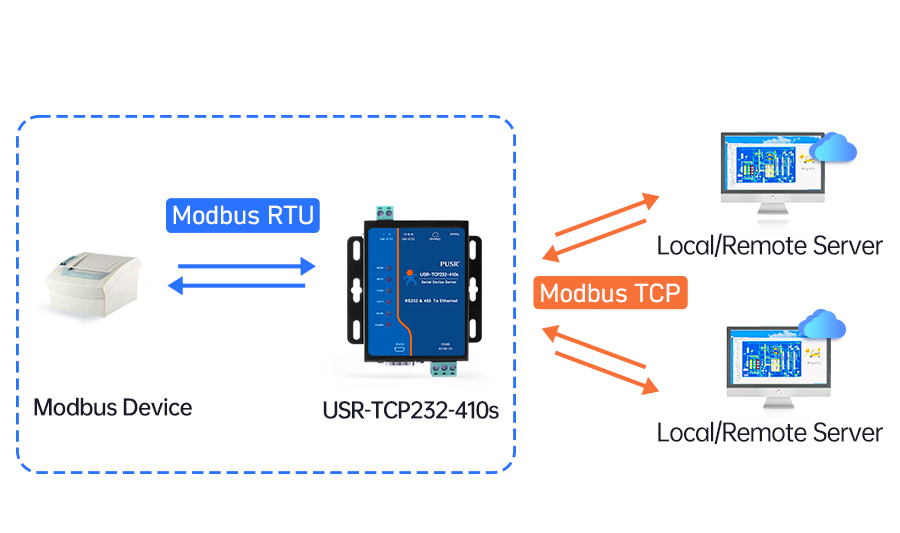

The USR-TCP232-410s is called a "Modbus Gateway" because one of its core design functions is to support bidirectional conversion between Modbus RTU and Modbus TCP protocols, acting as a bridge for the Modbus protocol between different physical layers (serial ports and Ethernet) to achieve interconnection between industrial equipment and networks. The following is a detailed explanation of why it is called a "Modbus Gateway":

4.1 Protocol Conversion Capability: Modbus RTU ↔ Modbus TCP

The core function of the Modbus Gateway 410s is bidirectional transparent transmission between serial ports (RS232/RS485) and Ethernet (TCP/IP), while the Modbus protocol itself supports two transmission modes:

Modbus RTU: An asynchronous communication protocol based on serial ports (such as RS485), widely used in industrial field devices.

Modbus TCP: A TCP/IP protocol based on Ethernet, suitable for remote monitoring and centralized management.

The Modbus Gateway 410s achieves seamless conversion between these two protocols through hardware and software design. For example:

Encapsulating Modbus RTU requests from RS485 devices into TCP/IP packets and sending them to a host computer on the network.

Decapsulating Modbus TCP instructions from the host computer into RS232/RS485 signals to drive field devices.

This capability makes it a "gateway" (Gateway) for the Modbus protocol between different physical layers, i.e., a Modbus Gateway.

4.2 Bidirectional Communication Support: Compatibility with Master-Slave Modes

The Modbus Gateway 410s not only supports protocol conversion but also has bidirectional communication capabilities, acting as both a Modbus master and a slave:

As a master: It actively polls Modbus RTU slave devices connected to the serial port and uploads data to the network via TCP/IP.

As a slave: It responds to Modbus TCP master requests from the network and feeds back data from serial devices to the master.

This flexibility enables it to adapt to different industrial scenarios, such as:

Centralized monitoring: Connecting multiple serial devices (such as sensors and PLCs) to a local area network via the Modbus Gateway 410s for unified management by a host computer.

Remote access: Transmitting Modbus RTU data from field devices to the cloud via the Internet for remote diagnosis and control.

4.3 Industrial-grade Design and Reliability

The hardware design of the Modbus Gateway 410s complies with industrial standards, further solidifying its positioning as a Modbus Gateway:

Wide operating temperature range: Supports environmental temperatures from -40°C to 85°C, adapting to harsh industrial field conditions.

Anti-electromagnetic interference: The network port adopts 2KV electromagnetic isolation, and the serial port supports hardware flow control (RTS/CTS) to ensure data transmission stability.

Redundant power supply: Supports DC 5-36V wide voltage input or terminal power supply to avoid communication interruptions caused by power failures.

These characteristics enable it to operate stably for a long time in industrial automation systems, meeting the high reliability requirements of a Modbus Gateway.

4.4 Advantages in Simplifying System Architecture

From the perspective of system integration, the USR-TCP232-410s, as a Modbus Gateway, has significant advantages:

Reducing intermediate links: Directly achieving interconnection between serial devices and networks without additional configuration of protocol converters or routers.

Cost reduction: Avoiding increased hardware costs due to in-depth protocol parsing through transparent transmission mode.

Easy deployment: Supporting web configuration, AT commands, or dedicated software settings for quick device networking.

For example, in a water plant monitoring system, the USR-TCP232-410s can convert serial water meter data into Modbus TCP and transmit it to the monitoring center via a local area network without modifying existing serial devices.

4.5 Comparison with Traditional Modbus Gateway Functions

Although the USR-TCP232-410s is called a "Modbus Gateway," its functions focus more on basic protocol conversion and general communication rather than providing complete advanced Modbus gateway functions (such as slave address mapping, data caching, and error handling). Its positioning is closer to that of a lightweight Modbus Gateway, suitable for the following scenarios:

Rapid device networking: Connecting Modbus devices that only support serial ports to the network without modifying host computer software.

Mixed protocol access: Simultaneously connecting RS232 and RS485 devices via dual serial ports and uniformly converting them into TCP/IP transmission.

Low-cost solutions: Meeting 80% of industrial needs through transparent transmission mode and avoiding cost increases due to advanced functions.

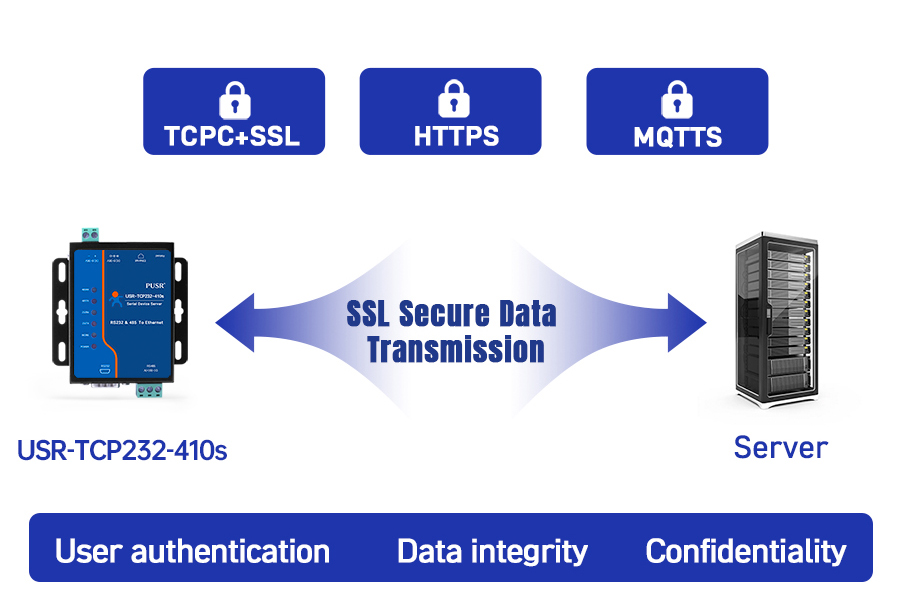

5. SSL Encryption Function: Guardian of Secure Transmission

The serial port to ethernet converter 410s supports SSL/TLS encryption, enabling the establishment of secure communication channels to prevent data from being stolen or tampered with during transmission. This function is particularly suitable for the following scenarios:

5.1 Remote Monitoring and Cloud Access

When devices access cloud platforms via the public network, SSL encryption protects data from man-in-the-middle attacks. For example, electricity meter data in smart grids needs to be encrypted and transmitted to energy management platforms to ensure the security of user electricity consumption information.

5.2 Financial and Medical Fields

In scenarios such as ATMs and medical equipment that require high security, SSL encryption can meet compliance requirements and avoid the leakage of sensitive data.

5.3 Industrial Control Systems (ICS)

Preventing hackers from infiltrating PLCs through unencrypted channels and causing production accidents. SSL encryption provides basic security protection for industrial IoT.

6. Edge Computing Function: Localized Intelligent Decision-making

The serial port to ethernet converter 410s has a built-in edge computing module that enables data preprocessing, rule engines, and local storage at the device end. This function is suitable for the following scenarios:

6.1 Real-time Response Requirements

In autonomous driving or robot control, edge computing can quickly process sensor data and trigger actions without relying on the cloud, reducing latency.

6.2 Bandwidth Optimization

In remote oil field monitoring, the serial port to ethernet converter 410s can filter invalid data (such as constant values) and only upload abnormal values, reducing network traffic and cloud storage costs.

6.3 Offline Operation Capability

When the network is interrupted, the edge computing module can continue to execute preset rules (such as alarm thresholds) to ensure uninterrupted system operation.

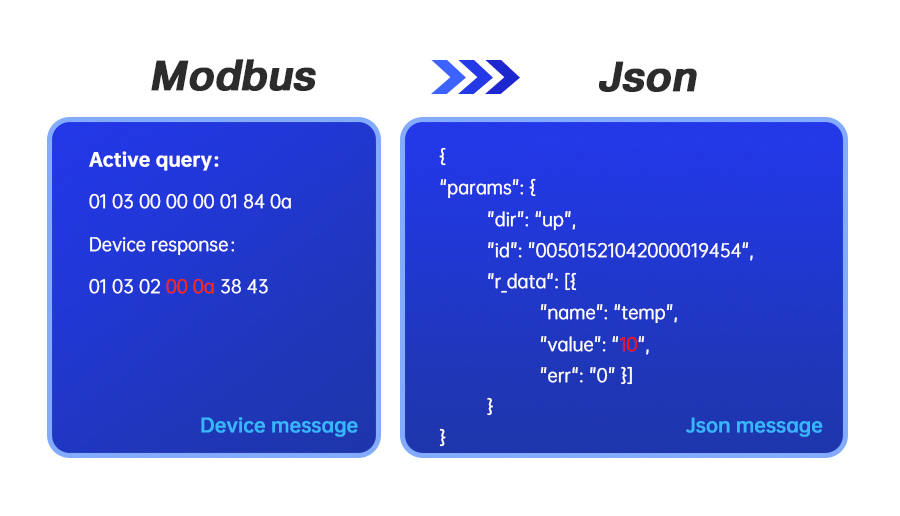

7.Custom JSON Function: Flexible Data Parsing and Integration

The serial port to ethernet converter 410s supports converting serial data into JSON format, facilitating integration with modern IT systems (such as databases and APIs). This function is particularly suitable for:

7.1 IoT Platform Integration

After encapsulating sensor data into JSON, it can be directly pushed to IoT platforms such as Alibaba Cloud and AWS without additional parsing.

7.2 Mobile Application Development

Smartphone apps can obtain device data through JSON interfaces for remote control and visualization.

7.3 Big Data Analytics

Structured JSON data is easier to process with tools such as Hadoop and Spark, supporting advanced applications such as predictive maintenance.

8. Data Encryption Transmission Methods: Multi-level Security Protection

In addition to SSL encryption, the serial port to ethernet converter 410s also supports:

8.1 AES-128/256 Encryption

End-to-end encryption of serial data, suitable for high-security scenarios such as military and government applications.

8.2 MAC Address Binding

Only allowing authorized devices to access to prevent illegal connections.

8.3 VPN Penetration

Supporting VPN protocols such as PPTP and L2TP to ensure the security of remote access.

Industrial-standard Hardware Protection: Reliability in Extreme Environments

9.The serial port to ethernet converter 410s adopts an industrial-grade design with the following characteristics:

Wide operating temperature range (-40°C~85°C): Suitable for high-temperature or low-temperature environments such as outdoors, metallurgy, and petroleum.

Anti-electromagnetic interference (EMI): Compliant with IEC 61000 standards, it can operate stably in strong electromagnetic fields (such as substations).

IP40 protection rating: Dustproof design, suitable for factory environments with a lot of dust.

Redundant power input: Supporting DC 9-36V wide voltage input and having overvoltage and reverse connection protection to ensure power supply reliability.

Typical Application Case:

In a steel plant, the USR-TCP232-410s connects a blast furnace temperature sensor (RS485) and a local controller (RS232), transmitting data to the monitoring center via Ethernet. Its industrial-grade design can withstand high temperatures and dust, while its SSL encryption and edge computing functions ensure data security and real-time performance.

Serial Port to Ethernet Converter 410s - The Communication Cornerstone of Industrial IoT

PUSR's serial port to ethernet converter 410s series redefines the technological boundaries of Serial to Ethernet Converters through innovative features such as dual serial port design, edge computing, and secure encryption. It not only solves the networking challenges of traditional industrial equipment but also, with its flexibility, security, and reliability, becomes a core communication component in fields such as smart factories, energy management, and smart cities. In the future evolution of industrial IoT, the serial port to ethernet converter 410 will continue to play its bridging role, driving the deep release of device interconnection and data value.